Laser Cutting Paper

Laser Cuttinging machines for Invitations and Greeting Cards, business cards, packaging, flyers or brochures, Stencils, Paper Models and Prototypes, etc.

Why choose Laser Cutting Paper?

Laser cutting paper delivers precision paper cutting and intricate paper designs that traditional methods cannot achieve. Its high-precision paper cutting is fast and efficient, perfect for invitations, packaging, or paper art.

Working with various paper types and thicknesses, custom paper cutting allows for personalized paper designs, unique patterns, and clean edge paper cutting.

As a non-contact paper cutting method, it reduces the risk of damaging delicate materials and ensures consistent laser cutting results. Minimal material waste makes paper laser cutting cost-effective and eco-friendly.

Overall, laser cutting paper combines efficiency, precision, and customization, providing creative potential for high-quality, personalized paper projects.

What types of Paper materials can be laser cutting?

Paper laser cutting works with a wide variety of materials, each offering unique characteristics and creative possibilities.

Printer Paper: Thin and commonly used for everyday printing, printer paper laser cutting is suitable for simple cut designs, prototypes, and test patterns.

Cardstock: Thicker than standard paper, cardstock laser cutting is ideal for greeting cards, invitations, and detailed projects. It produces clean edge paper cutting while maintaining structural integrity.

Vellum Paper: Translucent and smooth, vellum paper laser cutting is perfect for overlays, invitations, and art projects. Due to its delicate nature, careful handling ensures high-precision results.

Kraft Paper: Durable and naturally brown, kraft paper laser cutting is great for packaging, tags, and rustic-themed designs. Its distinct appearance makes it ideal for custom, engraved paper projects.

Laser Cutting Paper

Laser cutting paper provides precision paper cutting, speed, and versatility for highly detailed designs. It works with a wide range of paper types, including standard paper, cardstock, construction paper, vellum, kraft, tissue, watercolor, metallic, embossed, glitter, recycled, and handmade paper.

The process ensures clean edge paper cutting and allows for easy custom paper cutting, making it ideal for invitations, packaging, art, and other creative projects. Paper laser cutting is efficient, minimizes material waste, and is suitable for both intricate designs and high-volume production.

What kinds of Paper products can Laser Cutting?

Greeting Cards

Laser cutting paper enables the creation of intricate and unique designs on greeting cards. From simple cut-out shapes to elaborate lace-like patterns, precision paper cutting ensures each card is a high-quality engraved paper project. This technique is especially popular for birthdays, anniversaries, holidays, and other special occasions, allowing for custom paper cutting that makes every card truly memorable.

Invitations

Laser cutting paper can transform wedding invitations, party invites, and corporate event invitations into elegant keepsakes. With precision paper cutting, designs can feature delicate filigree, monograms, and custom shapes, producing high-quality engraved paper projects with a luxurious, professional finish. Custom paper cutting allows for personalized touches that make each invitation unique and memorable.

Packaging

Laser cutting paper is ideal for custom packaging solutions, including gift boxes, product packaging, and tags. Precision paper cutting allows for unique shapes and intricate designs that enhance both the visual appeal and functionality of packaging. Custom paper cutting is especially valuable for small businesses seeking to differentiate their products with distinctive, high-quality engraved paper projects.

Stationery

Laser cutting paper allows for personalized stationery, including letterheads, envelopes, and notebooks, to feature intricate laser-cut designs. With precision paper cutting, you can add company logos, detailed borders, or custom illustrations, creating custom paper cutting that reflects your brand identity and produces professional, high-quality engraved paper projects.

Art and Craft Projects

Laser cutting paper enables artists and crafters to create detailed papercuts, shadow boxes, and decorative elements. With precision paper cutting, even the most complex and delicate designs can be achieved, producing high-quality engraved paper projects. Custom paper cutting provides flexibility and accuracy, making it ideal for intricate artworks that are difficult to achieve by hand.

Business Cards

Laser cutting paper can elevate business cards with precision paper cutting, creating unique cut-out shapes, intricate patterns, and layered effects. Custom paper cutting allows businesses to produce distinctive engraved paper projects that leave a lasting impression on clients and partners.

And More…

Engraving Made Simple!

Printing and Operating Your Laser on Paper

You can print directly to your laser from any graphics software for paper laser cutting or engraved paper projects.

1. Design Blueprint: Prepare your digital design for paper cutting, specifying dimensions and engraving paths.

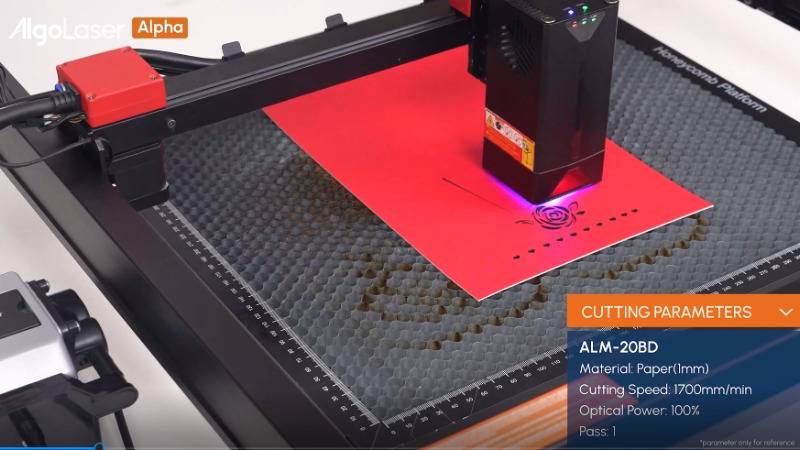

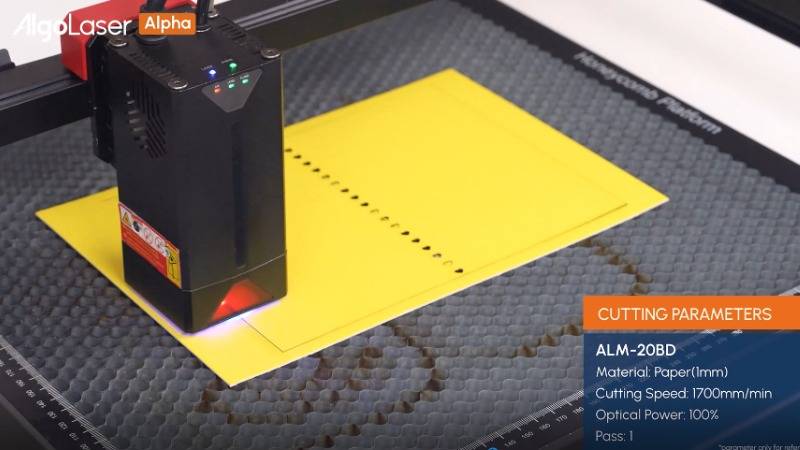

2. Material Settings: Adjust laser cutter settings for paper, including power and speed, for precision paper cutting and clean edges.

3. Operating the laser engraver: Secure the paper on the engraving bed, calibrate the laser, and initiate laser cutting paper. After completion, carefully remove the paper to maintain professional-quality custom paper cutting.

Step 1, Place the engraving material and focus.

Step 2, Set the parameter ofLiahtBurn.

Step 3, Set the image size and drag it into the engraving area.

Step 4, Click"Start" to run the laser engraver machine.

Step 5, Laser Cutting Paper.

Step 6, Paper laser cutting finished product display.

The Sample Club — You May Also Like…

Get fresh project inspiration every month with step-by-step guides and free SVG & G-code files for all your laser engraving and cutting projects!

Related to: Paper

How to laser engrave various materials?

Various projects and ideas about how laser engraving small business owners and freelance engravers use laser engravers and start a business.

Recommendations for Laser Engraving Machines

Whether you're working on single items or managing a heavy workload, an AlgoLaser Laser Engraver is the right solution. Check out our full product line for reliable and efficient engraving of Stones.

- Choosing a selection results in a full page refresh.