Laser Cutting & Engraving Wood

Laser cutters for MDF, plywood, pine, cherry, and other wood types!

Wood Engraving and Cutting with Laser Engraver

Diode Laser vs. Traditional Wood Engraving

| Category | Diode Laser Engraving | Traditional Wood Engraving |

|---|---|---|

| Precision & Detail | Ultra-fine resolution (0.06 mm); consistent photo-quality engraving | Depth and texture possible; fine detail limited by hand skill |

| Speed & Efficiency | Fast production; ideal for bulk orders or complex artwork | Time-intensive; better suited for one-off or artistic pieces |

| Ease of Use | Beginner-friendly software; learn basics in days | Steep learning curve; months to years of practice |

| Material Compatibility | Works on wood, leather, acrylic, slate, cork, metal (coated) | Primarily softwood and hardwood; limited to natural materials |

| Safety & Cleanliness | Low mess; requires safety goggles and proper ventilation | Wood dust and chips; rotary tools add noise and vibration |

| Customization | Precise and repeatable; perfect for logos, fonts, graphics | Hand-drawn charm; hard to reproduce identical results |

Woods You Can Engrave With a Diode Laser Engraver

A diode laser engraver can work with almost any type of wood, but not all woods produce the same results. Factors like grain pattern, density, natural oils, and resin content affect how an engraving appears. Some woods burn darker, creating bold contrast, while others reveal subtle, lighter tones. Understanding how different woods behave helps you select the ideal material for each project—whether creating Rustic Home Decor, personalized wooden gifts, or intricate laser-engraved craft pieces.

Here's a quick comparison of the most popular woods for laser engraving:

| Wood Type | Engraving Quality | Cost & Availability | Best Uses | Notes & Tips |

|---|---|---|---|---|

| MDF | Consistent, even engraving with no visible grain | Very affordable, widely available | Signs, bulk production, prototypes | Produces more smoke; good ventilation needed |

| Basswood | Smooth, fine detail with dark contrast | Low-cost, easy to find | Models, ornaments, craft projects | Light weight; engraves quickly |

| Pine | Rustic look, quick engraving but can be uneven | Affordable and common | Farmhouse décor, plaques, rustic signs | Resin and knots may cause darker spots |

| Cherry Wood | Sharp, detailed engravings with warm tones | Mid-range price, available at lumber suppliers | High-end gifts, nameplates, decorative art | Grain darkens naturally over time |

| Maple | Crisp, detailed results with light background | Moderate price, common hardwood | Logos, fine artwork, cutting boards | Dense wood; requires slower engraving speeds |

| Oak | Strong contrast with visible grain texture | Affordable hardwood | Rustic décor, furniture accents | Heavy grain can affect fine detail |

| Walnut | Bold engravings with rich dark tones | Higher cost, but widely used | Elegant décor, professional gifts | High density; excellent natural contrast |

| Birch | Clean, light surface with clear detail | Affordable and common | Signs, ornaments, lightweight crafts | Engraves evenly; great for beginners |

| Bamboo | Smooth surface with uniform results | Affordable and eco-friendly | Cutting boards, kitchenware, modern décor | Technically a grass, but engraves like wood |

| Cedar | Easy engraving with pleasant aroma | Moderate cost, regionally available | Outdoor signs, rustic projects | Knotty grain may cause uneven patterns |

By experimenting with different woods and adjusting your laser settings, you can unlock a wide range of creative results with your diode laser engraver.

Wood Relief Engraving with a Diode Laser

Wood relief engraving using a diode laser engraver is an exciting way to add depth and texture to a wooden surface without traditional carving tools. Unlike manual techniques, a diode laser uses a concentrated light beam to precisely remove layers of wood, creating laser-engraved wood designs, patterns, and textures. By adjusting the laser speed, power, and focus, makers can achieve varying depths—from shallow highlights to deeply sculpted features—giving the artwork a rich, three-dimensional quality.

Different types of wood respond uniquely to laser engraving on wood. Hardwoods like cherry, maple, oak, and walnut provide sharp contrast and clear detail due to their dense grain, making them ideal for intricate laser-engraved designs. Softwoods such as pine, cedar, and basswood andMDF is a smooth, budget-friendly option that engraves evenly, producing consistent relief without concerns about grain direction. Understanding the properties of each wood helps artists select the perfect material for their wood relief engraving projects.

Recommended Woods for Diode Laser Relief Engraving

| Wood Type | Engraving Depth | Detail & Clarity | Ease of Use | Best Uses |

|---|---|---|---|---|

| MDF | Medium | High | Easy | Bulk signs, prototypes, consistent reliefs |

| Basswood | Shallow to Medium | Very High | Very Easy | Craft models, ornaments, fine detailed relief |

| Pine | Medium | Medium | Easy | Rustic décor, plaques, artistic projects |

| Cherry Wood | Medium to Deep | Very High | Moderate | Gifts, nameplates, decorative art |

| Maple | Medium to Deep | Very High | Moderate | Logos, cutting boards, intricate designs |

| Oak | Medium | High | Moderate | Rustic décor, large panels, furniture accents |

| Walnut | Medium to Deep | High | Moderate | Elegant décor, professional-grade reliefs |

| Birch | Medium | High | Easy | Beginner-friendly projects, small ornaments |

| Cedar | Medium | Medium | Easy | Outdoor signs, rustic panels, scented pieces |

| Bamboo | Shallow to Medium | High | Easy | Eco-friendly décor, cutting boards, modern designs |

Tips for Choosing Wood for Relief Engraving

· For precision and fine detail, choose basswood, cherry, or maple.

· For rustic or textured designs, try pine, oak, or cedar.

· For budget-friendly bulk projects, MDF or birch works well.

· For high-contrast, elegant finishes, walnut or cherry are ideal.

Using this table alongside a diode laser ensures you can pick the best wood for your project, adjust settings confidently, and achieve consistent, professional-quality relief engravings every time.

What can you create?

Customized Wooden Signs

The laser engraver excels at produce.person, from business logos and Good to custom Home Decor Parts, delivering crisp edges, highly detailed imagery, and professional-quality results with every engraving project.

Artistic Photo Engravings

By laser engraving photographs on wood, diode laser engravers can transform cherished images into personalized wooden keepsakes, capturing the essence of memories with remarkable detail, high fidelity, and lasting beauty.

Elegant Inlays

Ideal for musical instruments and fine wooden furniture, diode laser engravers create intricate laser-engraved inlays and wood detailing that enhance both the aesthetic appeal and craftsmanship of each piece.

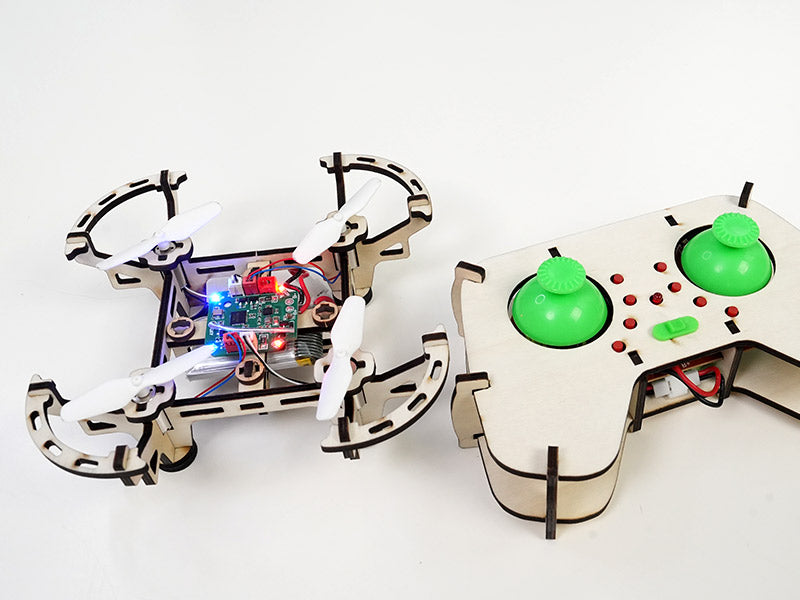

Rapid Prototyping

For designers, the diode laser engraver is an indispensable tool, allowing rapid transitions from digital design to laser-engraved prototypes using materials like MDF, plywood, and other engraved wood materials, streamlining both creative and production processes.

Personalized Gifts

The ability to laser engrave personalized items such as phone cases, jewelry boxes, and other keepsakes makes the diode laser engraver ideal for creating unique, heartfelt gifts that combine precision, durability, and custom design.

Architectural Models

Precision laser cutting enables the creation of highly detailed architectural models and prototypes, highlighting the diode laser engraver's exceptional accuracy and ability to produce intricate engraved designs with clean, sharp edges.

Educational Puzzles

Educational tools, learning aids, and puzzles benefit from the diode laser engraver's precision, which allows for cutting complex shapes and creating intricately laser-engraved designs, making learning more interactive, engaging, and visually appealing.

Decorative Art Pieces

Artists utilize diode laser engravers to craft intricate laser-engraved patterns and detailed scenes on wood panels, pushing the boundaries of traditional craftsmanship while enabling precision wood engraving and innovative laser-engraved artwork.

Functional Kitchenware

From cutting boards to coasters, diode laser engravers bring personalized laser engraving and refined etched designs to everyday items, adding both sophistication and a unique, custom touch to functional household objects.

And More…

Engraving Made Simple!

Engraving a Wooden Skateboard with AlgoOS

Creating laser-engraved designs on a wooden skateboard combines precision, personalization, and the power of a diode laser engraving machine . Follow these steps for professional results using AlgoOS and your Alpha MK2 or compatible laser engraver:

Step 1, Place the Wooden Surfboard Skateboard in the Engraving Area.

Step 2, Use the Focal Gauge to Adjust the Focal Length of the Laser Module.

Step3, Click on "Projects" Then "SD Card".

Step 4, Select the Prepared G-code File and Click the Frame Button.

Step 5, Start Engraving and Monitor the Process.

Step 6, Wooden Surfboard Skateboard Laser Engraving Completed .

The Sample Club — You May Also Like…

Get fresh project inspiration every month with step-by-step guides and free SVG & G-code files for all your laser engraving and cutting projects!

Related to: Wood

How to laser engrave various materials?

Various projects and ideas about how laser engraving small business owners and freelance engravers use laser engravers and start a business.

Recommendations for Laser Engraving Machines

Whether you're working on single items or managing a heavy workload, an AlgoLaser Laser Engraver is the right solution. Check out our full product line for reliable and efficient engraving of Stones.

- Choosing a selection results in a full page refresh.