Laser Cutting & Engraving Acrylic

Laser engravers & Cutting machines for acrylic

Why choose cutting and engraving Acrylic?

Laser cutting acrylic and acrylic laser engraving deliver high precision, producing laser engraved acrylic with clean edges and intricate detail. This precision laser cutting ensures sharp lines and consistent quality, making acrylic ideal for professional and creative applications.

Acrylic is widely used for laser cut acrylic signage, displays, decorations, and prototypes. With acrylic laser cutting and engraving, creators can produce custom acrylic designs, logos, and text with ease, supporting both commercial production and DIY projects.

Laser technology also enables full customization. Personalized acrylic products, engraved acrylic logos, and acrylic text engraving can be tailored to exact requirements, delivering tailored acrylic solutions with reliable repeatability.

What types of Acrylic materials can be cutted and engrave?

Acrylic is a versatile material prized for its optical clarity, durability, and flexibility. Laser cutting acrylic and acrylic laser engraving process acrylic with high precision, making it ideal for signage, displays, décor, and product fabrication. Various acrylic materials suit acrylic laser cutting and engraving, each offering distinct performance and visual effects.

Cast Acrylic

Cast acrylic laser cutting is ideal for detailed and artistic projects. With excellent optical clarity and a smooth surface, cast acrylic engraving produces clean edges and a frosted finish. Its uniform composition and low internal stress make it perfect for intricate designs and fine text.

Extruded Acrylic

Extruded acrylic laser cutting is a cost-effective option for high-volume production. Though thickness may vary slightly, it works well for extruded acrylic engraving and basic cutting. This material suits projects that prioritize budget and efficiency over deep engraving detail.

Colored Acrylic Sheets

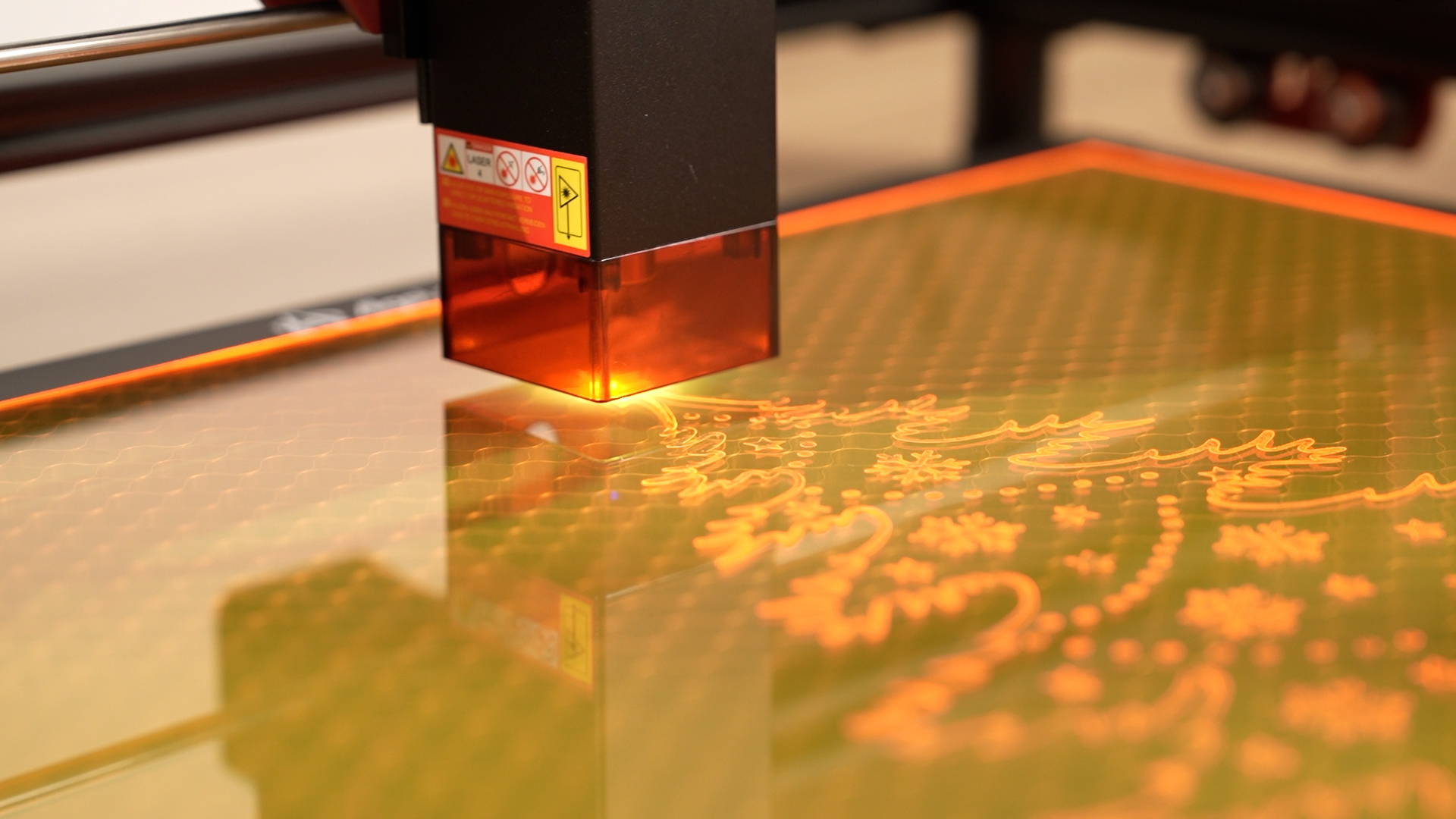

Colored acrylic laser cutting and engraving enable bold, eye-catching designs. Available in many vibrant hues, these sheets are commonly used for laser cut acrylic signage, retail displays, and decorative projects. Engraving creates strong contrast, highlighting logos, text, and patterns.

Specialized Acrylic Materials

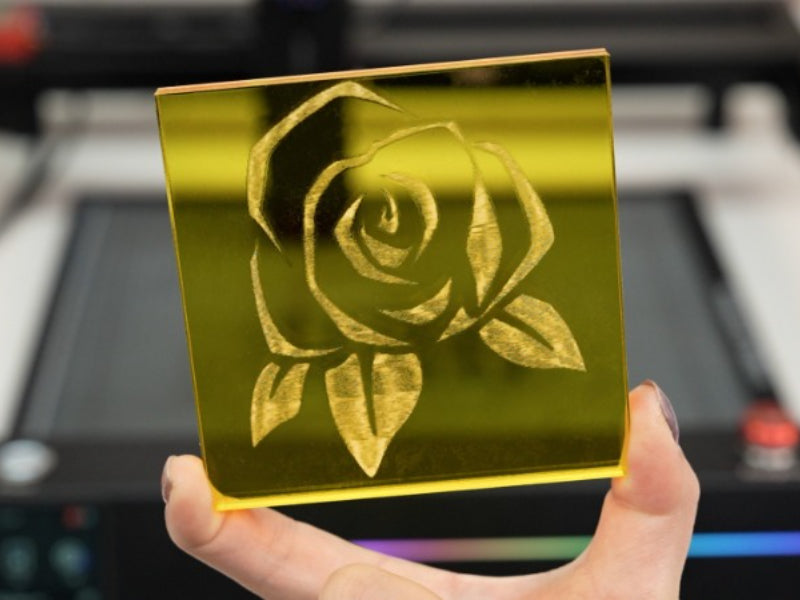

Specialty variants, such as mirrored acrylic laser cutting and fluorescent acrylic engraving, add unique visual effects. They are popular for creative, architectural, and promotional applications. With proper settings, acrylic sheet laser cutting delivers clean, precise results even on reflective or translucent surfaces.

Conclusion: Acrylic materials suitable for laser cutting acrylic and laser engraved acrylic include cast, extruded, colored, and specialized acrylics. Using professional acrylic laser cutting ensures clean edges, precise acrylic material engraving, and limitless customization possibilities for a wide range of applications.

Laser Cutting Acrylic

Laser cutting acrylic delivers precision laser cutting, polished acrylic edges, and intricate acrylic designs with professional results.

Easy Setup: Start with high-quality acrylic sheets for laser cutting and a digital design for acrylic cutting using vector graphics software. Define your dimensions and cutting paths for accurate results.

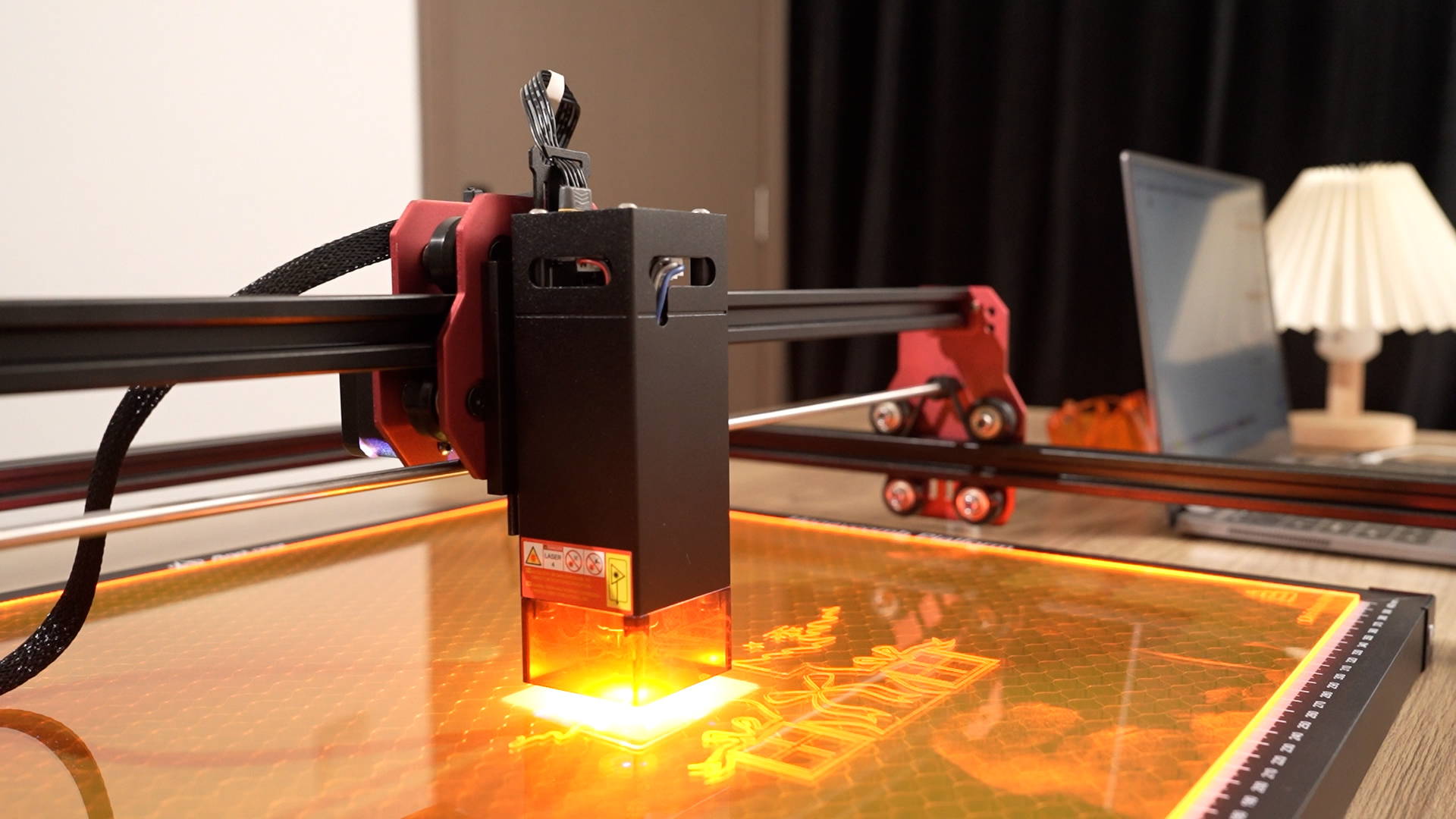

Precise Cutting: Set your laser cutter for acrylic, adjusting power and speed based on thickness. Secure the acrylic on the cutting bed for stable, damage-free cutting. The laser beam follows your design, melting and vaporizing the material to produce clean edge acrylic cutting with minimal post-processing.

Safe Handling: After cutting, allow the acrylic to cool. Carefully remove the cut acrylic sheets to maintain flawless edges and avoid damage.

Laser cutting acrylic is ideal for signage, displays, décor, and custom fabrication, combining speed, accuracy, and versatility in every project.

Laser Engraving Acrylic

Laser engraving acrylic provides a precision laser engraving method for adding intricate acrylic designs, logos, or text with professional results.

Prepare Your Material and Design: Start with high-quality acrylic sheets for engraving, ensuring they are free from scratches or imperfections. Create your digital design for acrylic engraving using vector graphics software, specifying engraving depth and fine details.

Set Up Your Laser Engraver: Adjust your laser engraver settings for acrylic, including power, speed, and resolution, based on the acrylic type and desired outcome. Secure the acrylic on the engraving bed, ensuring it lies flat and stable, and verify the alignment for precise placement.

Engraving Process: Initiate the engraving process. The laser beam etches the design onto the surface, vaporizing a thin layer of acrylic to leave a permanent, high-precision engraved acrylic mark. This process ensures consistent detail and clean, professional results.

Post-Processing: After engraving, carefully remove the engraved acrylic from the bed. Clean off any debris to reveal crisp, polished details and maintain flawless edges.

Acrylic laser engraving is ideal for custom signage, awards, decorative projects, and personalized items, combining accuracy, versatility, and lasting quality.

Laser cutting and engraving for what kinds of Acrylic products?

Signage and Displays

Acrylic signs are a popular choice for businesses, events, and retail spaces because of their durability and visual appeal. Laser cutting acrylic enables the creation of intricate acrylic designs and custom shapes, while acrylic laser engraving adds logos, text, and graphics with precision laser engraving. This combination ensures that engraved acrylic signage stands out with professional, high-quality results.

Art and Decor

Artists and designers leverage laser cutting acrylic and acrylic laser engraving to produce stunning engraved acrylic artwork and decorative pieces. From wall art to tabletop sculptures, precision laser engraving allows for intricate patterns, textures, and layered designs, adding depth and complexity to custom acrylic creations.

Custom Awards and Trophies

Laser-cut acrylic awards and trophies provide a modern and elegant alternative to traditional materials. Using acrylic laser engraving, you can add recipient names, dates, and achievements, producing custom engraved acrylic awards that are unique, professional, and memorable keepsakes.

Architectural Models

Architects and model makers use laser cutting acrylic to create detailed scale models of buildings and structures. The precision laser cutting ensures accurate representation of architectural elements, while acrylic laser engraving adds fine details such as windows, doors, and textures, resulting in highly realistic engraved acrylic models.

Jewelry and Accessories

Laser cutting acrylic enables the creation of intricate shapes and designs, making it perfect for crafting acrylic jewelry and accessories. With acrylic laser engraving, you can add custom patterns, monograms, or decorative elements, enhancing the aesthetic appeal of engraved acrylic pieces.

Prototyping and Product Development

Acrylic is a popular material for prototyping thanks to its affordability and ease of machining. Laser cutting acrylic and acrylic laser engraving allow for rapid iteration and custom acrylic prototypes across industries such as electronics, packaging, and consumer goods, providing precision, speed, and versatility in product development.

Personalized Gifts

Laser-cut and engraved acrylic products make thoughtful and personalized acrylic gifts for special occasions such as weddings, birthdays, and anniversaries. From custom engraved acrylic photo frames to keepsake boxes, acrylic laser engraving allows for endless creative possibilities and unique, memorable presents.

Industrial Applications

Acrylic parts and components are widely used in industrial applications, including machinery, electronics, and automotive manufacturing. Laser cutting acrylic ensures precise shaping and sizing, while acrylic laser engraving can add part numbers, logos, or identification markings, producing accurate and traceable engraved acrylic components.

And More…

Engraving Made Simple!

Printing and Operating Your Laser on Acrylic

You can print directly to your laser from any graphics software for laser cutting acrylic or acrylic laser engraving.

1. Design Blueprint: Prepare your digital design for acrylic cutting or engraving, specifying dimensions, cutting paths, and engraving details.

2. Material Settings: Adjust laser cutter settings for acrylic, including power, speed, and resolution based on acrylic type and thickness.

3. Operating the Laser Engraving Machine: Secure the acrylic on the engraving or cutting bed, calibrate the laser, and initiate high-precision acrylic cutting or engraving. After completion, carefully remove the engraved or cut acrylic and clean debris for polished acrylic edges.

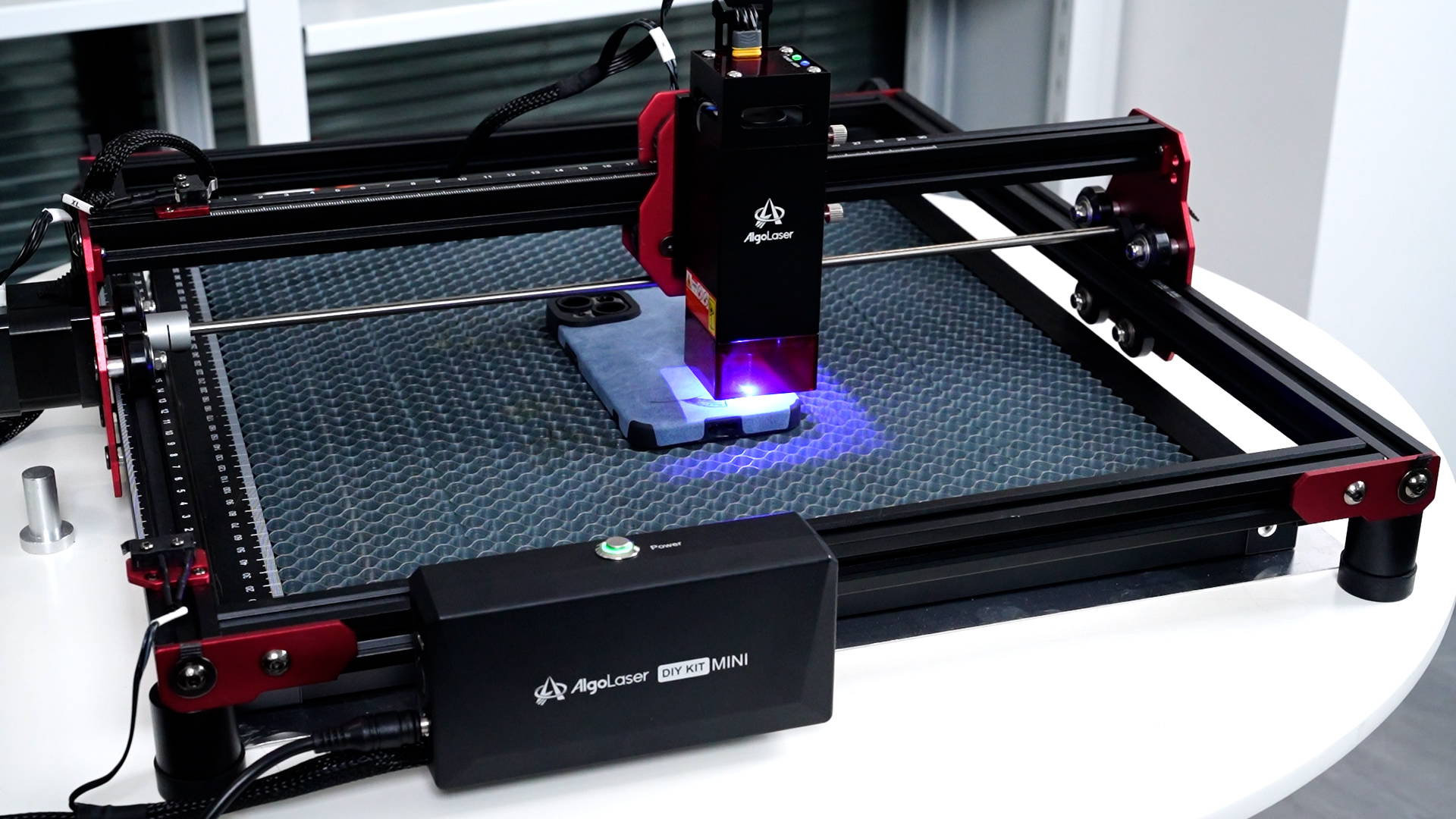

Step 1, power on the machine, and wait for the module stopping at the original point.

Step 2, open the LightBurn. Choose the corresponding machine. Wait for the console to display "OK" .

Step 3, drag the prepared pattern into the workspace. The recommended parameters for cutting and engraving acrylic are shown in the video.

Step 4, click “Frame” button to determine the processing area.

Step 5, click "Start" .

Step 6, Acrylic laser engraving finished product display.

The Sample Club — You May Also Like…

Get fresh project inspiration every month with step-by-step guides and free SVG & G-code files for all your laser engraving and cutting projects!

Related to: Acrylic

How to laser engrave various materials?

Various projects and ideas about how laser engraving small business owners and freelance engravers use laser engravers and start a business.

Recommendations for Laser Engraving Machines

Whether you're working on single items or managing a heavy workload, an AlgoLaser Laser Engraver is the right solution. Check out our full product line for reliable and efficient engraving of Stones.