1. Can I use thicker plywood than 3mm?

Yes, but keep in mind that thicker wood requires multiple passes or slower cutting speeds. For most music box designs, 3mm plywood offers the ideal balance of flexibility and durability.

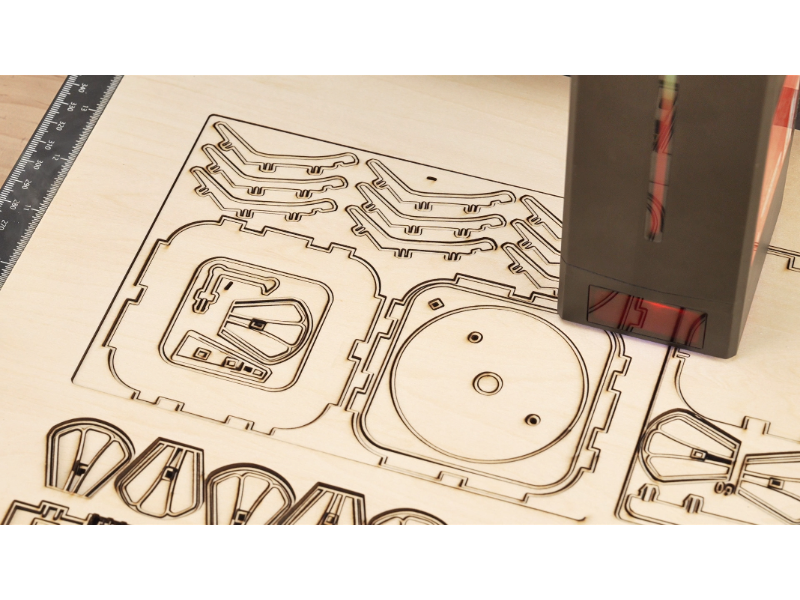

2. Will the laser burn the edges of the wood?

A slight darkening on the edges is normal, giving the wood a nice rustic finish. If you want cleaner edges, you can lightly sand them or adjust air assist to reduce scorching.

3. What file format works best for cutting?

SVG files are recommended because they preserve vector paths that the laser can follow exactly. DXF files can also work but may need conversion for compatibility.

4. Can I engrave a custom pattern or message on the lid?

Absolutely! That’s one of the best parts of using a laser engraver. You can personalize the lid with text, logos, or even a short dedication before cutting.

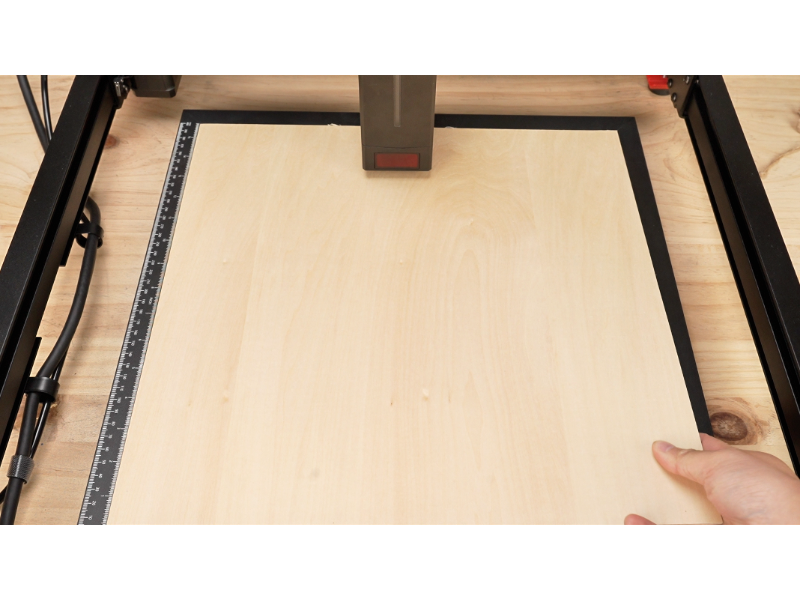

5. How do I ensure my cuts are consistent?

Make sure the plywood is flat, the laser is properly focused, and your parameters are correctly set. Using the built-in preview function to frame the job area helps too.

6. Can the Alpha MK2 handle larger or more complex projects?

Definitely. With its 40W power, dual-core CPU, and 32GB memory, the Alpha MK2 can handle multi-layer designs and even large-scale cutting projects without lag or overheating.