Why We Don't Choose to Buy a Cheap Laser Engraving Machine

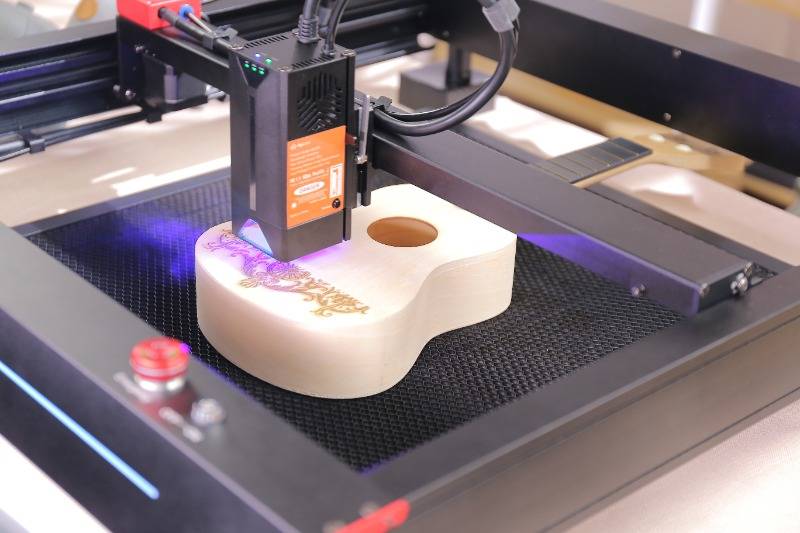

Laser engraving, a technology that has rapidly gained popularity in recent years, is revolutionizing how we personalize and transform various materials. This precise and versatile method uses concentrated laser beams to etch or cut designs into a range of materials, from wood and acrylic to glass and metal. The applications are boundless, spanning diverse industries, and laser engraving has emerged as a game-changer in the world of customization and design.

What laser engraving is

Laser engraving is a technique that utilizes high-energy laser beams to create permanent, high-precision marks or cuts on different materials. The laser's intense heat vaporizes or melts the material's surface, leaving behind intricate designs, logos, or even functional components.

The role of laser engravers in various industries

Laser engravers have carved a niche in numerous industries. In the realm of personalization, they're used to create customized gifts, jewelry, and promotional products. The technology finds a home in the manufacturing and industrial sectors, too, where it's employed for precise cutting, engraving, and marking on materials like textiles, plastics, and metals. Architects and designers use laser engravers to construct intricate scale models, and the medical field relies on them for precise part fabrication. The possibilities are immense, and the applications continue to expand.

Why quality matters in laser engraving

The role of quality in laser engraving is paramount. The distinction between a high-quality laser engraving machine and a cheap alternative can be seen not only in the precision and speed of the engraving but also in the durability of the machine and the excellence of the final product.

Overview of the reasons for advising against cheap laser engravers

In the following sections, we will delve into the pitfalls of choosing super cheap laser engraving machines. While the initial cost savings may be appealing, these low-cost options come with hidden costs and potential drawbacks that can significantly impact your productivity and the quality of your work. We'll explore topics such as subpar engraving quality, inferior component quality, the lack of essential safety measures, material compatibility issues, engraving limitations, and the economic considerations of investing in laser engravers. By understanding these potential drawbacks, you can make an informed decision that aligns with your business needs and long-term goals.

Understanding Laser Engravers

To comprehend why quality matters in the world of laser engraving, it's crucial to first understand the technology itself. Laser engraving machines, while they might seem complex, are essentially advanced tools designed for precision and versatility.

Brief Explanation of the Different Types of Laser Engravers

Laser engravers come in several distinct types, each with its unique characteristics and applications:

CO2 Laser Engravers: These machines use carbon dioxide gas as the laser medium and are widely used for engraving and cutting non-metal materials such as wood, acrylic, and leather. CO2 lasers are known for their excellent precision and are commonly used in arts, crafts, and the manufacturing industry.

Fiber Laser Engravers

Fiber lasers use solid-state technology and are exceptionally well-suited for metal engraving, marking, and cutting. They provide high power and precision, making them indispensable in industries like aerospace, automotive, and jewelry.

Diode Laser Engravers

Diode lasers are compact and efficient, primarily used for engraving and marking applications on various materials. Their lower power makes them suitable for smaller-scale, hobbyist, or entry-level machines.

The Mechanism Behind Laser Engraving

The core principle of laser engraving is the generation of a concentrated beam of light in a specific wavelength (typically CO2 or fiber lasers) that interacts with the surface of the material. The laser beam creates intense heat, which vaporizes or melts the material, leaving permanent marks or cuts with a high degree of precision.

Differentiating High-Quality from Cheap Laser Engravers

At first glance, it may be challenging to distinguish between high-quality and cheap laser engraving machines, especially for those new to the technology. However, several key factors set them apart:

Laser Source: High-quality machines are equipped with powerful and reliable laser sources. These sources offer consistent power and precision, resulting in superior engraving quality and faster processing speeds. Cheap alternatives often use less powerful and less reliable lasers, leading to uneven and inaccurate engraving.

Optics

The optical components in a laser engraving machine play a crucial role in focusing the laser beam. High-quality machines incorporate top-notch optics that ensure accurate and consistent focus, resulting in clean and precise engravings. Cheap machines often use subpar optics, which can lead to inconsistent engraving depth and quality.

Control Systems

High-quality machines feature sophisticated control systems that allow for fine-tuning and customization of engraving parameters. These systems provide greater flexibility and control over the engraving process. Cheap machines may use basic or outdated control systems, limiting your ability to adjust settings and optimize your work.

Durability

Quality engraving machines are built to last. They use robust materials and are designed to withstand continuous use in professional and industrial settings. In contrast, cheap machines often cut costs by using subpar components and materials, making them more prone to breakdowns and wear and tear.

In summary, understanding laser engravers and the differences between high-quality and cheap machines is vital. High-quality machines offer superior performance, precision, and durability due to their powerful laser sources, top-notch optics, advanced control systems, and robust build quality. Cheap alternatives may save you money initially, but they often come with hidden costs in the form of subpar engraving quality, frequent breakdowns, and limited control, ultimately impacting your productivity and the quality of your work.

The Pitfalls of Cheap Laser Engravers

Laser engraving is a technology that offers precision, flexibility, and efficiency. However, not all laser engraving machines are created equal. In this section, we'll delve into the pitfalls of choosing super cheap laser engraving machines. While the initial cost savings may seem enticing, these budget options often come with hidden costs and potential drawbacks that can significantly impact the quality of your work and the safety of your operations.

A. Subpar Engraving Quality - Discuss why cheaper models often deliver lesser quality engraving outcomes

One of the primary pitfalls of super cheap laser engraving machines is their subpar engraving quality. While these machines may promise precision and detail, they often fall short of delivering the desired results.

Here's why:

Power and Precision

High-quality laser engraving machines use powerful and reliable laser sources to ensure consistent power and precision. Cheap alternatives, on the other hand, often employ lower-powered lasers. This difference in power can result in uneven and inaccurate engravings. Fine details may be lost, and the final product may not meet the desired quality standards.

Inconsistent Depth

Achieving consistent engraving depth is crucial for professional and high-quality work. High-quality machines use top-notch optics and control systems to ensure precise focus and depth. In contrast, cheap machines may utilize subpar optics and control systems, leading to inconsistencies in engraving depth. This means that one part of your engraving may be deeper or lighter than another, resulting in uneven and unprofessional-looking designs.

Speed and Efficiency

Cheap laser engravers tend to be slower and less efficient than their high-quality counterparts. This sluggish performance can impact productivity, especially in a business setting. The need for slower processing times can lead to delays and bottlenecks in your workflow.

Ultimately, the subpar engraving quality of cheap laser engraving machines can result in unsatisfactory products and wasted materials. Customers may be disappointed, and the need to rework or redo engraving jobs can eat into your time and resources.

B. Inferior Component Quality - Discuss how cheaper models use lower-quality parts affecting machine lifespan

Another significant drawback of super cheap laser engraving machines is the use of inferior components, affecting the overall durability and lifespan of the machine. Here's how:

Build Quality

High-quality laser engraving machines are constructed with durable materials and top-notch components. They are built to withstand the demands of professional and industrial use. In contrast, cheap machines often cut corners by using subpar materials and components. These machines are more prone to wear and tear, frequent breakdowns, and shorter lifespans.

Frequent Repairs

Cheap machines may require more frequent repairs and maintenance. The need for replacement parts and repairs can quickly add up in terms of expenses. Downtime while waiting for repairs can also result in lost productivity and revenue.

Hidden Costs

Over time, the cumulative effect of hidden costs, such as maintenance and replacement parts, can make the total cost of ownership for a cheap machine comparable to or even higher than that of a more expensive, high-quality machine.

C. Lack of Essential Safety Measures - Highlight safety risks associated with cheap laser engravers - Importance of operator safety

Safety should be a paramount concern when operating laser engraving machines. Unfortunately, cheap laser engravers often cut costs by omitting essential safety measures, which can pose significant risks to operators and the environment. Here's why safety is a concern:

Eye and Skin Hazards

The laser beam used in engraving is highly concentrated and can be harmful to the eyes and skin. High-quality machines incorporate safety features like enclosed work areas, interlocks, and emergency stop buttons to minimize the risk of accidental exposure. Cheap machines may lack these safety features, increasing the risk of eye and skin hazards for operators.

Fume Extraction

Laser engraving generates fumes and smoke, especially when engraving certain materials. High-quality machines are equipped with efficient fume extraction systems that remove these harmful byproducts, ensuring a safe working environment. Cheap machines may lack proper fume extraction, resulting in poor air quality and potential health risks for operators.

Fire Hazards

Laser engraving machines can generate heat, and in the absence of adequate safety measures, there is a risk of fire. High-quality machines include fire detection and suppression systems, while cheaper models may lack these critical safety features.

Legal and Regulatory Compliance

Many jurisdictions have specific regulations regarding the safe operation of laser machines. Non-compliance with these regulations can result in fines, legal action, or damage to your reputation. High-quality machines are often designed with regulatory compliance in mind, while cheap alternatives may lack the necessary safety features to meet these requirements.

In conclusion, super cheap laser engraving machines often compromise on engraving quality, use inferior components that affect machine lifespan, and lack essential safety measures. These pitfalls can result in subpar work, frequent repairs, and safety risks, ultimately leading to hidden costs and potential harm to operators. It's crucial to prioritize quality and safety when choosing a laser engraving machine, even if it means a higher initial investment. Your long-term productivity, work quality, and safety should always be paramount.

Assessing the Functionality

In the realm of laser engraving, functionality is king. The ability to work with a wide range of materials, achieve versatile engraving parameters, and employ advanced software can significantly impact the efficiency and productivity of your engraving endeavors. Unfortunately, super cheap laser engraving machines tend to fall short in these critical aspects. In this section, we'll explore why assessing the functionality of your engraving equipment is vital and why cheaper models may not be up to the task.

A. Limited Material Compatibility - Explain why cheaper models may not work with a wide range of materials

Material compatibility is a fundamental consideration when investing in a laser engraving machine. High-quality machines are renowned for their ability to work with a broad spectrum of materials, from wood and acrylic to glass and metal. However, cheaper models often come with limitations in this regard.

Here's why:

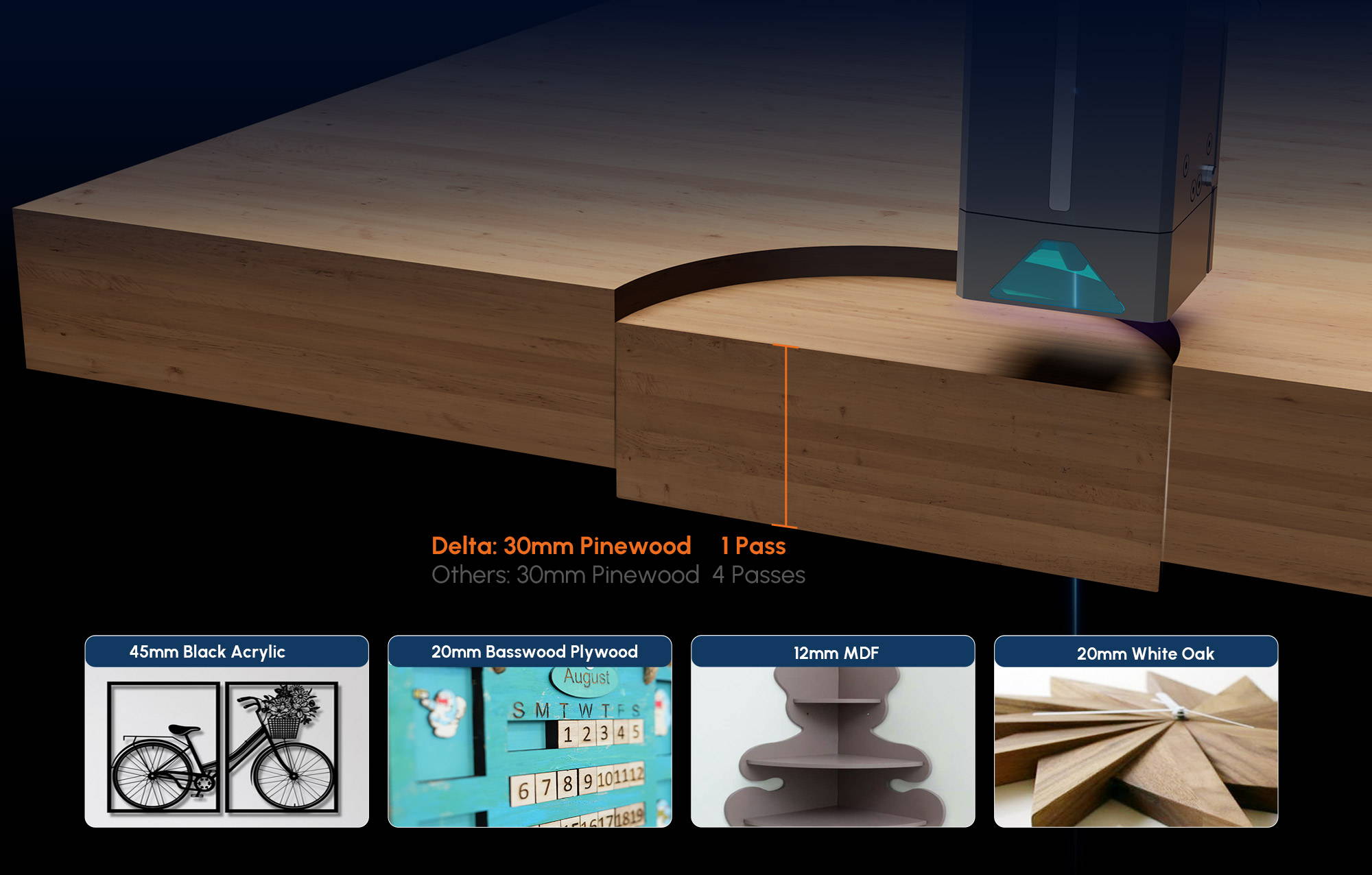

Laser Power

The type and power of the laser source play a crucial role in determining a machine's material compatibility. High-quality laser engraving machines use powerful laser sources that can handle a wide variety of materials, both thick and thin. In contrast, super cheap models frequently employ lower-powered lasers, which may struggle to engrave or cut through certain materials effectively.

Material Handling

The design and features of the engraving machine also impact material compatibility. High-quality machines often have adjustable bed heights, rotary attachments, and other accessories that allow for versatile material handling. Cheaper alternatives may lack these features, making it challenging to work with unconventional materials or irregularly shaped items.

Lens and Optics

The quality of the lens and optics used in a laser engraving machine can significantly affect material compatibility. High-quality machines are equipped with top-notch optics that ensure precise focus and depth control. Cheap machines often feature subpar optics, leading to inconsistent engraving results on different materials.

Software Flexibility

Software plays a crucial role in material compatibility. High-quality machines are usually compatible with a wide range of design software, allowing for flexibility and customization. Cheaper machines may have limited software compatibility, making it challenging to work with different file formats or design programs.

In summary, limited material compatibility in super cheap laser engraving machines can hinder your ability to expand your offerings and cater to a diverse clientele. The inability to engrave specific materials effectively can result in missed business opportunities and limited revenue potential.

B. Restricted Engraving Capability - Discuss how a lesser price tag often signifies limited engraving parameters

Engraving capability refers to the machine's range of parameters and settings, including engraving speed, power, and precision. High-quality machines offer a wide spectrum of options, allowing for precise control and customization. Cheaper models, however, tend to come with restricted engraving parameters.

Here's why:

Laser Power and Speed

High-quality laser engravers typically offer a broader range of laser power and engraving speed settings. This flexibility allows for fine-tuning to achieve different levels of depth and detail on various materials. In contrast, super cheap models often have limited power and speed settings, making it challenging to adapt to specific engraving requirements.

Depth and Detail

Achieving consistent engraving depth and intricate detail is essential for professional work. High-quality machines are equipped with advanced control systems that provide precision and consistency. Cheaper machines may lack these advanced control systems, resulting in shallower engravings and less detail.

Quality Control

High-quality machines often undergo rigorous quality control and testing, ensuring that they meet industry standards for precision and consistency. Cheap machines may not undergo such rigorous testing, leading to variations in engraving quality and accuracy.

Engraving Area

The size of the engraving area is another factor to consider. High-quality machines are available in various sizes to accommodate different project requirements. Cheaper models may have smaller engraving areas, limiting the size of materials you can work with and the scope of your projects.

Restricted engraving capability can lead to unsatisfactory results, where the final product lacks the level of detail, depth, or precision required. This can affect customer satisfaction and potentially result in rework or wasted materials.

C. Limited Software Capabilities - Highlight the drawbacks of cheaper models having less advanced or outdated software

Software is the brains behind a laser engraving machine, and its capabilities significantly impact the efficiency and quality of the engraving process. High-quality machines are often paired with advanced software that offers a wide range of features and functionalities. Cheaper models, however, tend to lag in software capabilities.

Here's why:

Design Flexibility

High-quality engraving software allows for intricate and complex designs. It can handle a variety of file formats, including vector graphics and bitmap images, enabling flexibility in design. Cheaper models may have limited compatibility with design software, restricting your ability to work with diverse design formats.

Customization

Advanced software provides a wide array of parameters that can be adjusted, including power, speed, and resolution. This level of customization is essential for adapting to different materials and project requirements. Cheaper models may have simplified software with fewer parameters, limiting your ability to fine-tune your engraving settings.

Compatibility

High-quality laser engraving machines are designed to work with a range of software, providing seamless integration with popular design programs. Cheaper models may not have the same level of compatibility, requiring additional steps or conversions to prepare designs for engraving.

Updates and Support

High-quality machine manufacturers often provide regular software updates and support, ensuring that your equipment remains up-to-date and functional. Cheaper models may lack ongoing support and updates, leaving you with outdated or incompatible software.

Inadequate software capabilities can result in inefficiency, limitations in design possibilities, and difficulties in adapting to different materials and projects. This can hinder your productivity and the quality of your work, ultimately affecting customer satisfaction and your ability to compete in the market.

In conclusion, assessing the functionality of a laser engraving machine is crucial for achieving versatile and high-quality results. Super cheap laser engraving machines often come with limitations in material compatibility, restricted engraving parameters, and limited software capabilities. These limitations can hinder your ability to expand your offerings, achieve precise and detailed engravings, and efficiently adapt to different materials and project requirements. When choosing a laser engraving machine, it's essential to consider the functionality and how it aligns with your business needs and goals.

Economic Considerations

While the upfront cost of a super cheap laser engraving machine may seem like a tempting proposition, it's essential to look beyond the initial investment. The economic considerations associated with cheap laser engravers often reveal a stark contrast between short-term savings and long-term costs. In this section, we'll explore the hidden expenses and challenges that arise when choosing a low-cost machine.

A. Short-Term vs. Long-Term Costs - Break Down Potential Additional Costs Associated with Cheap Laser Engravers - Discuss Maintenance Frequency and Costs

Maintenance Frequency

Cheap laser engraving machines frequently require more frequent maintenance compared to their high-quality counterparts. The lower-quality components, including the laser source, optics, and mechanical parts, tend to wear out quickly. As a result, you may find yourself investing significant time and money in maintaining and repairing your machine. This increased maintenance frequency can lead to downtime, disrupting your workflow and potentially costing you valuable business opportunities.

Replacement Parts

Cheap machines often use inferior components that are more prone to failure. When these components break down, you'll need to purchase replacement parts. However, finding replacement parts for budget machines can be challenging and expensive. High-quality machines usually have a readily available supply of quality replacement parts, reducing the downtime and costs associated with repairs.

Hidden Costs

Over time, the cumulative effect of maintenance and replacement parts can make the total cost of ownership for a cheap machine comparable to or even higher than that of a more expensive, high-quality machine. What initially seemed like a cost-effective solution can quickly turn into a financial burden, erasing the initial savings.

Reduced Lifespan

Cheap laser engraving machines have a significantly shorter lifespan due to the wear and tear on their components. This means you'll need to replace the entire machine more frequently, incurring substantial costs and resulting in further downtime.

In summary, the short-term cost savings of a super cheap laser engraving machine can quickly be overshadowed by the long-term expenses associated with frequent maintenance, replacement parts, and reduced machine lifespan.

B. The Trade-off Between Price and Efficiency - Discuss how cheaper models may have lower productivity, slowing down business progress

Efficiency is a critical factor in any business, and it's essential to consider how a laser engraving machine's price may impact its efficiency and, subsequently, your business progress. Here's why choosing a cheaper machine can lead to a trade-off between price and efficiency:

Productivity

High-quality laser engraving machines are designed for efficiency and productivity. They offer faster engraving speeds, better precision, and more consistent results. In contrast, cheaper models often lack the power and precision required for professional or industrial applications. Slower engraving speeds can lead to longer production times, reducing your overall productivity and ability to meet customer demand.

Quality

The quality of the engraving is directly related to efficiency. High-quality machines produce consistent, high-precision engravings, reducing the need for rework and ensuring customer satisfaction. Cheaper models may struggle to deliver the same level of quality, potentially resulting in more time spent on re-engraving or customer complaints.

Customization

High-quality machines often offer advanced software and settings that allow for precise customization of engraving parameters. This customization can significantly enhance your efficiency and versatility. Cheaper models tend to have limited software capabilities and engraving parameters, reducing your ability to adapt to different materials and project requirements.

Competitiveness

In today's competitive market, efficiency and the ability to meet customer demands quickly are crucial. A laser engraving machine that operates slowly or produces subpar results can hinder your competitiveness. It may lead to lost business opportunities and lower revenue potential.

In conclusion, the trade-off between price and efficiency is a critical consideration when choosing a laser engraving machine. While a super cheap machine may save you money upfront, it can slow down your business progress, reduce productivity, and hinder your competitiveness. The hidden costs associated with reduced efficiency and the need for rework can negate the initial savings, ultimately impacting your bottom line. It's essential to weigh the upfront cost against the long-term benefits and efficiency of a high-quality laser engraving machine when making your investment decision.

Choosing Wisely: Things to Consider While Investing in a Laser Engraver

Investing in a laser engraving machine is a decision that can have a significant impact on your business, whether you're a hobbyist or an industrial professional. When it comes to choosing the right machine, there are crucial factors to consider that go beyond the initial cost. In this section, we'll explore these considerations to help you make an informed decision that aligns with your long-term goals.

A. Quality and Reliability - Highlight why investing in a quality product pays off in the long run

Durability: High-quality laser engraving machines are built to last. They are constructed with robust materials and top-notch components that can withstand the demands of continuous use. This durability ensures that your machine will have a longer lifespan, reducing the need for frequent replacements and repairs.

Consistency

Quality engraving machines offer consistent results. The precision, power, and speed they provide result in high-quality engravings with minimal variation. This consistency is essential for professional work and customer satisfaction.

Material Versatility

Quality machines are designed to work with a wide range of materials, from wood and acrylic to metal and glass. This material versatility allows you to diversify your offerings and meet a broader spectrum of customer demands.

Resale Value

High-quality machines often have a better resale value. When the time comes to upgrade or change your machine, you can recoup a significant portion of your initial investment. In contrast, super cheap machines have limited resale value.

Warranty

Quality machines typically come with comprehensive warranties that provide peace of mind and protection against unforeseen issues. These warranties offer added security, reducing the risk of unexpected repair or replacement costs.

Choosing a high-quality laser engraving machine may involve a higher upfront cost, but the long-term benefits in terms of durability, consistency, material versatility, and resale value can significantly outweigh the initial investment.

B. After-sales Support - Discuss the importance of customer support and after-sales service which cheaper brands might not offer

Technical Support

High-quality manufacturers often provide robust technical support to assist customers with any issues or questions. Whether it's troubleshooting a problem or helping with software-related concerns, having access to knowledgeable and responsive support can save you time and frustration.

Repairs and Maintenance

Quality manufacturers typically offer maintenance and repair services for their machines. This ensures that your machine remains in top working condition and reduces downtime.

Software Updates: High-quality manufacturers frequently provide software updates to enhance the performance and capabilities of your machine. These updates can improve efficiency, expand material compatibility, and provide additional features.

Training and Resources

Quality manufacturers may offer training resources and materials to help you make the most of your machine. This can include instructional videos, user manuals, and online communities for sharing tips and insights.

C. Research, Reviews, and Reputation - The importance of researching product reviews and the reputation of the company before making a purchase

Product Reviews

Before making a significant investment in a laser engraving machine, it's essential to research and read product reviews. Reviews from other users provide valuable insights into the machine's performance, reliability, and any potential issues. Consider both expert reviews and user feedback to get a comprehensive understanding.

Company Reputation

Investigate the reputation of the manufacturer. Established and reputable companies are more likely to produce high-quality machines and offer excellent customer support. Look for manufacturers with a track record of producing reliable equipment.

Ask for Recommendations: Don't hesitate to ask for recommendations from fellow engravers or businesses in your industry. They can provide firsthand insights into their experiences with specific brands and models.

Demo and Testing

Whenever possible, try out the machine or request a demo. Testing the machine yourself can help you gauge its performance and ease of use, ensuring it aligns with your specific needs.

In conclusion, investing in a laser engraving machine is a significant decision, and it's crucial to consider quality, after-sales support, and reputation. Quality and reliability in a machine can result in long-term cost savings and consistent results. Additionally, having access to responsive customer support and maintenance services is essential for addressing any issues that may arise. Researching product reviews and the reputation of the manufacturer can help you make an informed decision that aligns with your business goals and ensures you're not lured by the hidden costs of super-cheap alternatives.

Conclusion

In the world of laser engraving, the allure of super cheap machines is undeniable. However, as we've explored in this comprehensive guide, the hidden costs associated with these budget options can far outweigh the initial savings. Choosing a laser engraving machine should be a decision driven by careful consideration of long-term factors rather than a focus on the immediate price tag.

Throughout this article, We've highlighted several critical reasons why super cheap laser engraving machines often prove to be unwise investments:

Subpar Engraving Quality

Low-quality results can lead to customer dissatisfaction, rework, and lost business opportunities.

Inferior Component Quality

Frequent breakdowns and costly replacement parts can erode any initial savings.

Lack of Essential Safety Measures

Operator safety is paramount, and cheap machines often compromise on safety features.

Limited Material Compatibility

The inability to work with various materials can hinder your ability to diversify your offerings.

Restricted Engraving Capability

Reduced engraving parameters can limit your creative possibilities and efficiency.

Limited Software Capabilities

Outdated or limited software can hamper your productivity and design flexibility.

Short-Term vs. Long-Term Costs

Frequent maintenance, repairs, and shorter lifespans can turn the initial savings into long-term financial burdens.

The Trade-off between Price and Efficiency

Slower processing and lower quality can impact your productivity and competitiveness.

Choosing Wisely

Prioritizing quality, after-sales support, and researching reviews and reputation is essential for making an informed investment.

In conclusion, while it's natural to be cost-conscious, it's equally important to see the bigger picture. The initial savings of a super cheap laser engraving machine can be enticing, but the hidden costs and limitations may significantly impact your business and your peace of mind. By considering the long-term benefits of quality, efficient performance, and robust support, you'll be better equipped to choose wisely and realize the full value of your investment. When it comes to laser engraving, quality, reliability, and support are not expenses but invaluable assets that ensure your success in the long run.

- Choosing a selection results in a full page refresh.