Mastering the Art of Laser Engraving on Stainless Steel

In the world of modern fabrication and customization, laser engraving has emerged as a powerful tool for adding intricate and precise designs to a variety of materials. Stainless steel, renowned for its durability and sleek appearance, may seem challenging to work with, but laser engraving has opened up a realm of possibilities for creating personalized and intricate designs on stainless steel surfaces. We will delve into the art of laser engraving on stainless steel, exploring its feasibility, the techniques involved, and showcasing some impressive projects. Additionally, we'll discuss the best laser engraving machines for tackling stainless steel with finesse.

Free SVG & Gcode Files for Laser Engraving & Cutting can be found here, wich you can import into our laser cutters directly.

Can Stainless Steel Be Laser Engraved?

Laser engraving on stainless steel may seem counterintuitive, given the material's hardness and resistance to abrasion. However, with the right equipment and techniques, stainless steel can indeed be engraved with precision. The key lies in the power and wavelength of the laser, which can interact with the surface of stainless steel to create intricate designs, markings, and patterns. The process involves localized heating and ablation of the material, leaving behind a permanent and visually appealing mark.

How Can Stainless Steel Be Engraved with a Laser?

Engraving stainless steel with a laser involves the following steps:

1. Choosing the Right Laser

To engrave stainless steel effectively, you need a laser engraving machine equipped with a fiber laser source. Fiber lasers offer high power and excellent beam quality, making them suitable for marking and engraving metals.

2. Surface Preparation

Ensure the stainless steel surface is clean and free from any contaminants, oils, or debris. Cleaning the surface with isopropyl alcohol can help promote adhesion and enhance the quality of the engraving.

3. Design Preparation

Create or import your design into laser engraving software. Vector files, such as those in SVG or DXF formats, work well for precise and detailed designs. Adjust the design's size and position to fit the stainless steel piece.

4. Focusing and Settings

Properly focus the laser on the stainless steel surface. Adjust the laser settings, including power and speed, to achieve the desired engraving depth and quality. For stainless steel, higher power settings are typically required.

5. Test Run

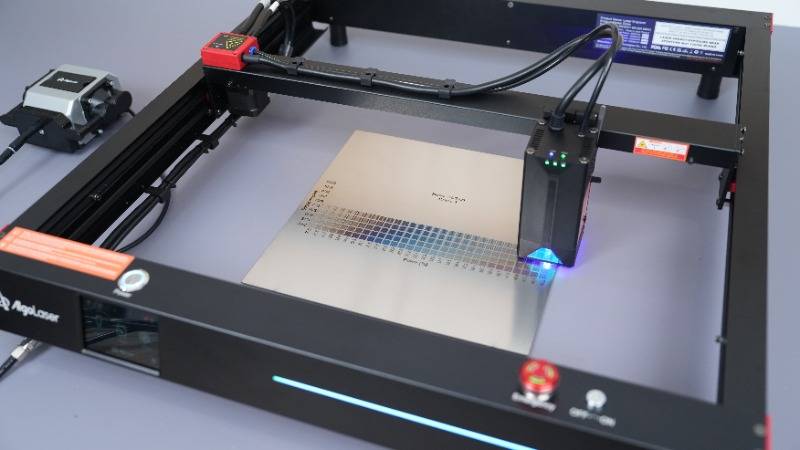

Before engraving your final design, perform a test run on a similar piece of stainless steel to ensure the settings are correct and the engraving appears as expected.

6. Engraving

Once you're satisfied with the test run, proceed to engrave the actual piece. Ensure the stainless steel is securely positioned within the laser engraving machine, and initiate the engraving process.

7. Cleaning and Inspection

After engraving, clean the stainless steel surface to remove any residues or debris. Inspect the engraving to ensure it meets your quality standards.

8. Post-Processing (Optional)

Depending on your design and preferences, you can enhance the engraved stainless steel by adding paint or other finishes to create contrast and visual appeal.

How to Engrave Stainless Steel with a Laser Engraver?

The process of engraving stainless steel with a laser engravermay seem straightforward, but achieving exceptional results requires attention to detail. Here's a step-by-step guide to help you master this art:

Step 1: Prepare Your Design

Create or select the design you want to engrave on stainless steel. Use vector-based design software to ensure high precision and accuracy.

Step 2: Clean the Stainless Steel

Wipe the stainless steel surface clean with isopropyl alcohol or another suitable cleaner to remove any oils or contaminants.

Step 3: Secure the Stainless Steel

Position the stainless steel piece securely within the laser engraving machine. Make sure it's level and well-supported to prevent movement during engraving.

Step 4: Focus the Laser

Properly focus the laser beam on the stainless steel surface. This step is crucial for achieving a sharp and clear engraving.

Step 5: Adjust Laser Settings

Configure the laser settings, including power, speed, and frequency, based on the specifics of your engraving project. Stainless steel typically requires higher power settings for effective engraving.

Step 6: Test Run

Perform a test run on a scrap piece of stainless steel to verify that the settings are optimal. Adjust as needed to achieve the desired engraving depth and quality.

Step 7: Begin Engraving

Once satisfied with the test run, proceed to engrave the final piece. Ensure that the laser engraving machine operates smoothly and that the stainless steel is secure.

Step 8: Monitor the Process

Keep a close eye on the engraving process, ensuring that everything proceeds as planned. If any issues arise, be prepared to pause or stop the machine.

Step 9: Post-Processing (Optional)

After engraving is complete, clean the stainless steel to remove any residues. If desired, you can apply paint or other finishes to enhance the appearance of the engraving.

Step 10: Inspect and Admire

Examine the finished engraving, appreciating the precision and intricacy of the design on the stainless steel surface.

The Best Laser Engraved Stainless Steel Projects

Laser engraving on stainless steel opens the door to a wide range of creative and functional projects. Here are some impressive examples to spark your inspiration:

1. Personalized Jewelry

Create custom pendants, bracelets, and rings with names, dates, or meaningful symbols laser-engraved on stainless steel.

2. Custom Knife Blades

Engrave intricate designs, logos, or patterns on knife blades for a unique and personalized touch.

3. Industrial Labels and Tags

Produce durable and permanent identification tags and labels for machinery, equipment, and tools in industrial settings.

4. Personalized Drinkware

Add names, initials, or custom designs to stainless steel tumblers, mugs, and flasks for a personalized drinking experience.

5. Architectural Signage

Create sleek and modern signage for homes, offices, or commercial spaces using laser-engraved stainless steel plates.

6. Promotional Items

Design branded promotional items like keychains, business card holders, or USB drives with your logo or message on stainless steel.

7. Art and Décor

Craft stunning pieces of art or home décor by laser engraving intricate designs or inspirational quotes on stainless steel panels or sculptures.

8. Functional Gadgets

Engrave stainless steel tools, such as multitools or flashlights, to make them stand out and serve as unique gifts.

The Best Laser Engraving Machine for Stainless Steel

To achieve exceptional results when laser engraving on stainless steel, the choice of the right laser engraving machine is paramount. Several factors should be considered when selecting the best machine for your stainless steel engraving needs:

1. Power and Wavelength

Opt for a laser engraving machine with a high-power fiber laser source, as this is essential for effectively marking and engraving metals like stainless steel.

2. Software Compatibility

Ensure that the machine is compatible with a variety of design and engraving software, allowing you flexibility in creating and customizing your designs.

3. Bed Size and Flexibility

The size of the engraving bed determines the maximum dimensions of your stainless steel pieces. Choose a machine with a bed size suitable for your intended projects.

4. Autofocus and Z-Axis Control

Features like autofocus and Z-axis control enhance the machine's ability to adapt to various material thicknesses and maintain a consistent focal distance.

5. Durability and Build Quality

Look for a robust and durable machine, as engraving on stainless steel can put the equipment through demanding tasks.

6. Speed and Precision

The machine's engraving speed and precision are critical for achieving fine details and high-quality results. Consider models with advanced motion control systems for superior accuracy.

7. Cooling System

A reliable cooling system is crucial, as it ensures the laser source remains at an optimal temperature during extended engraving sessions.

8. Technical Support and Training

Access to technical support and training resources can be invaluable, especially if you're new to laser engraving. Look for a manufacturer or distributor that offers comprehensive support.

9. User-Friendly Interface

An intuitive and user-friendly interface simplifies the engraving process, making it accessible to users of varying experience levels.

When selecting the best laser engraving machine for your specific needs, it's essential to consider factors such as the size of your projects, your budget, and the level of technical support required. Additionally, you should choose a machine that offers the appropriate power and capabilities for your intended applications on stainless steel.

In conclusion, laser engraving on stainless steel is a versatile and precise method for adding intricate designs and markings to a wide range of products and projects. With the right equipment and techniques, you can transform stainless steel into personalized and visually striking pieces. Whether you're creating jewelry, industrial labels, or custom drinkware, laser engraving opens up a world of creative possibilities. To ensure the best results, choose a laser engraving machine that meets your specific requirements and provides the power and precision necessary for stainless steel engraving.

Free SVG & Gcode Files for Laser Engraving & Cutting can be found here, wich you can import into our laser cutters directly.

- Choosing a selection results in a full page refresh.