Laser Engraving and Cutting Acrylic vs. Traditional Methods: A Complete Comparison

Acrylic has become one of the most widely used materials in signage, awards, displays, decorative items, and prototypes. Known for its glass-like clarity, lightweight durability, and adaptability, it's a favorite among makers, businesses, and artists alike. But when it comes to shaping, engraving, and cutting acrylic, the method you choose makes a big difference in quality, speed, and cost.

Two main approaches dominate the industry today: laser engraving and cutting versus traditional mechanical methods like CNC routing, saw cutting, and manual engraving. While both techniques can get the job done, they are far from equal. This blog will explore the key differences and advantages of each method, so you can decide which is best for your projects.

1. Precision and Detail

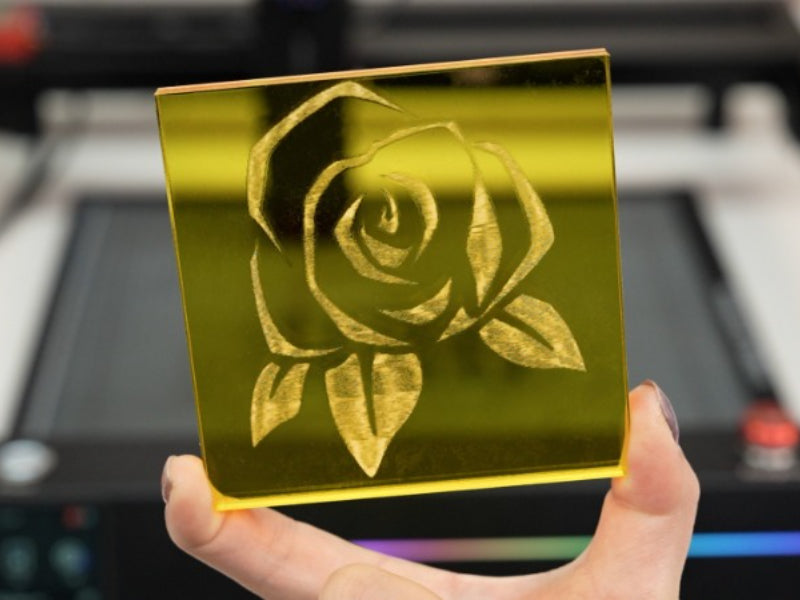

A laser engraver delivers unmatched accuracy. The laser beam is incredibly fine — typically between 0.05 mm and 0.1 mm — which allows for extremely detailed designs. Whether it's intricate text, complex geometric patterns, or even photo-like engravings, a laser can reproduce them with ease.

Traditional methods, such as CNC routers or milling tools, can achieve decent results but struggle with very fine details. Mechanical engraving tools leave tool marks and can't reach the microscopic resolution that a laser provides. For applications that demand perfection, lasers clearly lead the way.

✅ Winner: Laser engraving

2. Edge Quality

The finish of acrylic edges is often what separates professional-looking work from amateur results. With saws, drills, or routers, edges often come out cloudy, rough, or even jagged. Additional steps like flame polishing or sanding are usually required to achieve a smooth, glossy edge.

Laser cutting, on the other hand, melts the acrylic as it cuts. This process produces crystal-clear, flame-polished edges immediately, with no extra finishing needed. For industries like signage or displays where appearance is everything, this is a major advantage.

✅ Winner: Laser cutting

image credit: CardsPaperLove - Etsy

3. Speed and Efficiency

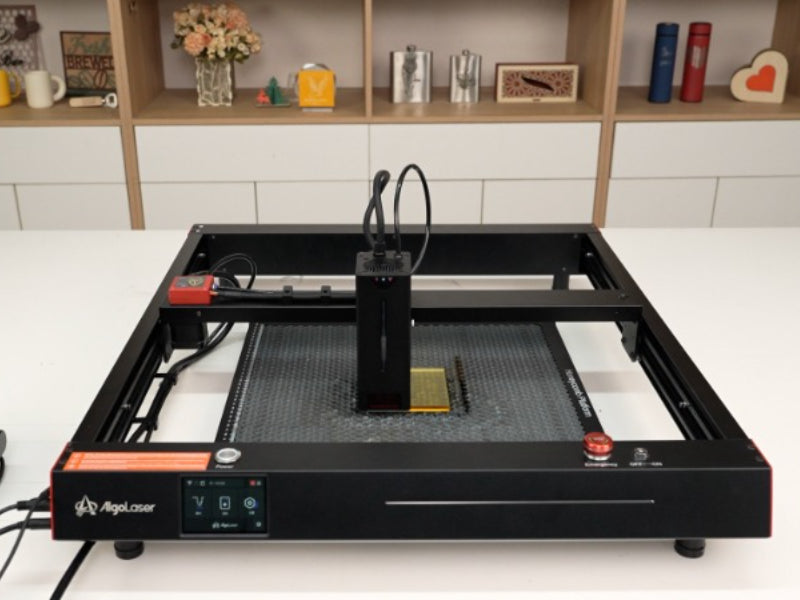

A laser engraver is fast not only in operation but also in setup. There's no need for clamping, adjusting cutting tools, or switching between machines. A single laser system can engrave and cut in one continuous process, saving significant time.

By contrast, traditional acrylic cutting often involves multiple steps. You might cut with one tool, engrave with another, and then polish afterward. Each step slows production and requires more labor.

✅ Winner: Laser engraving and cutting

image credit: runningwithscissorss - Etsy

4. Material Waste and Risk of Damage

Traditional cutting methods exert physical force on the acrylic, which can cause cracks, chips, or breakage if the tool is dull or misaligned. Additionally, the kerf — the width of the cut — is larger, which leads to more wasted material.

Lasers, being non-contact tools, eliminate most of these issues. The laser beam has an extremely thin kerf, reducing material waste and maximizing precision. Since there's no blade touching the surface, there's also little risk of damaging the acrylic during cutting.

✅ Winner: Laser cutting

image credit: ADifferentRouteStore - Etsy

5. Design Flexibility

When it comes to design freedom, the laser engraver is hard to beat. Any digital design created in CAD or graphic software can be directly cut or engraved into acrylic. Whether it's a custom sign, layered artwork, or complex shapes with interior cutouts, lasers handle it with ease.

Traditional methods, while effective for straight cuts or simple designs, struggle with highly detailed or intricate shapes. Customization is possible but often requires expensive tooling and extra setup time.

✅ Winner: Laser engraving

image credit: FranJohnsonHouse - Etsy

6. Maintenance and Wear

Mechanical tools wear down over time. Router bits, saw blades, and engraving tips need frequent replacement, and dull tools reduce the quality of cuts. Traditional cutting also generates dust and debris, requiring constant cleanup.

Laser engravers don't suffer from tool wear since there's no direct contact with the material. The only regular maintenance involves cleaning lenses and mirrors. This makes lasers more reliable in the long run.

✅ Winner: Laser systems

7. Cost Considerations

Upfront cost is one area where traditional methods have the advantage. Saws, drills, and CNC routers are generally cheaper to buy initially compared to a laser engraver.

However, when you consider long-term efficiency, reduced labor, less waste, and lower maintenance, laser systems often prove to be more cost-effective. For businesses that rely heavily on acrylic work, the return on investment with lasers is substantial.

✅ Winner: Traditional for initial cost, laser for long-term value

image credit: DryforgeCreative - Etsy

8. Applications

· Laser Engraving & Cutting Acrylic:

Best for signage, awards, displays, acrylic jewelry, decorative panels, promotional items, and fine artistic work. Perfect for both custom one-offs and batch production.

· Traditional Acrylic Methods:

Still practical for very thick acrylic sheets (25 mm+), large construction panels, or basic projects where edge quality and fine detail are less critical.

image credit: CardsPaperLove - Etsy

Laser Engraving vs. Traditional Acrylic Cutting: Quick Comparison

| Category | Laser Engraving & Cutting | Traditional Methods (CNC, Saw, Drill, Milling) |

|---|---|---|

| Precision & Detail | Extremely fine (0.05–0.1 mm beam), supports intricate designs and photo engraving | Limited to simple text, logos, and shapes |

| Edge Quality | Smooth, flame-polished, crystal clear edges | Rough, cloudy, or jagged edges that need polishing |

| Speed & Efficiency | Fast setup, can cut and engrave in one process | Slower, requires clamping, tool changes, and post-polishing |

| Material Waste | Minimal waste, very thin kerf, non-contact cutting prevents cracks | Wider cuts, higher waste, risk of chipping or cracking |

| Design Flexibility | Almost unlimited — curves, detailed patterns, fine lettering | Limited to straight cuts and simple routed shapes |

| Maintenance & Wear | No tool wear, only lens/mirror cleaning needed | Tools dull and need frequent replacement |

| Upfront Cost | Higher investment, but cost-effective long-term | Lower initial cost but higher long-term expense |

| Best Applications | Signage, awards, displays, jewelry, custom art, fine details | Thick acrylic sheets, large panels, basic shapes |

Frequently Asked Questions (FAQs)

1. Can a laser engraver cut all types of acrylic?

Yes. A laser engraver works with both cast acrylic (ideal for engraving, frosted finish) and extruded acrylic (better for clean cutting, engraving looks more transparent).

2. How thick of an acrylic sheet can a laser engraver cut?

Most hobby and professional lasers can cut acrylic up to 10–20 mm thick, depending on power. For sheets over 25 mm, traditional methods are often more efficient.

3. Do laser-cut acrylic edges need polishing?

No. Laser cutting produces flame-polished edges automatically, unlike traditional methods, which often require sanding or flame finishing.

4. Is laser engraving acrylic faster than traditional engraving?

Yes. Lasers eliminate clamping, tool changes, and polishing steps, making the process significantly faster and more efficient.

5. Is a laser engraver expensive to maintain?

Not really. Maintenance usually involves cleaning optics and replacing occasional components, but there are no cutting blades to dull, which keeps upkeep costs low.

6. Can beginners use a laser engraver for acrylic projects?

Absolutely. Modern laser engravers are designed with user-friendly software and presets, making them easy for beginners while still powerful enough for professionals.

image credit: LuckandLuck - Etsy

Final Thoughts

When weighing laser engraving and cutting acrylic against traditional methods, the benefits of laser technology are clear. From smoother edges and faster production to greater design freedom and lower maintenance, lasers consistently deliver superior results.

Traditional methods still hold value for very thick materials and workshops seeking a lower entry cost. But for businesses and makers who care about efficiency, precision, and professional-quality results, a laser engraver is the smarter choice.

Whether you're crafting detailed signage, personalized awards, or stunning decorative pieces, investing in a laser engraver will not only save you time but also open up creative possibilities that traditional tools simply can't match.

- Choosing a selection results in a full page refresh.