How To Laser Engrave Stainless Steel Flask With LaserGRBL

Laser engraving is a sophisticated technology that has revolutionized the way we personalize, brand, and decorate a wide range of materials, including metal, wood, glass, and plastic. At its core, laser engraving uses a highly focused beam of light (laser) to etch or vaporize the material surface, creating precise, permanent designs without direct contact with the object being engraved. This non-contact engraving method not only preserves the integrity of the material but also allows for intricate detailing that would be difficult, if not impossible, to achieve through traditional mechanical engraving methods.

The laser in a laser engraver is controlled by computer software, which directs the laser’s path over the material's surface based on a digital design. This design can be as simple as text or as complex as a detailed image. The intensity, speed, and focus of the laser beam can be adjusted to achieve different depths and shades, allowing for remarkable versatility and precision in the finished product.

Free SVG & Gcode Files for Laser Engraving & Cutting can be found here, wich you can import into our laser cutters directly.

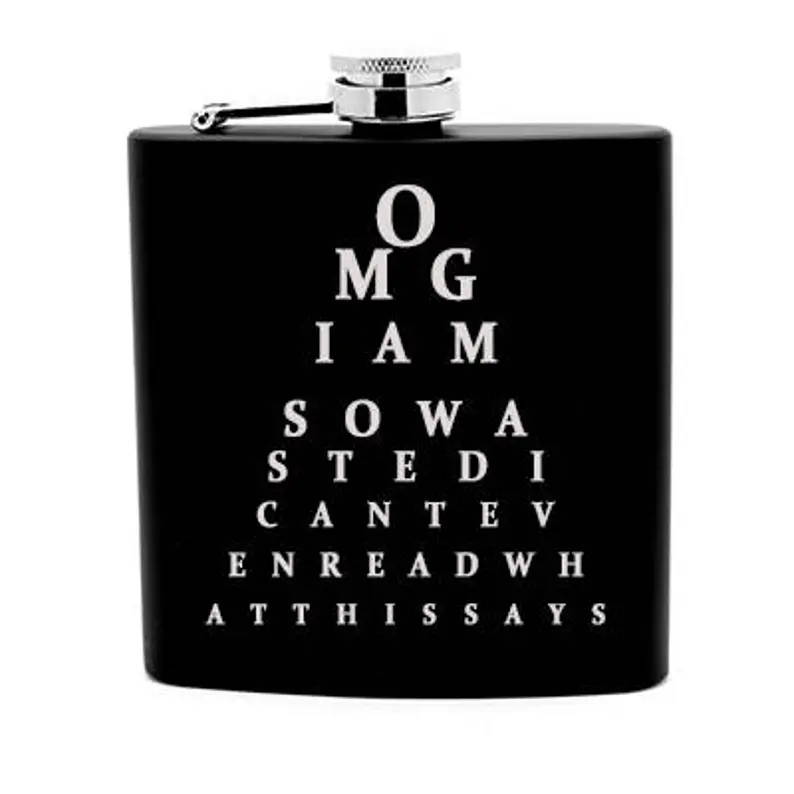

image credit: BKGift - Etsy

Overview of Laser Engraving Machines Suitable for Stainless Steel

When it comes to laser engraving stainless steel flasks, the choice of machinery extends to three primary types: fiber laser engravers, CO2 laser engravers (with a metal marking compound), and diode laser engravers. Each has its unique strengths and is capable of marking stainless steel effectively under the right conditions.

Fiber Laser Engravers

These are the gold standard for engraving metals, including stainless steel. They use a solid-state laser source to create a very fine, intense laser beam that directly interacts with the metal surface, resulting in a high-contrast, precise engraving. Fiber lasers are highly efficient, produce clear and permanent marks, and are suitable for both text and intricate designs.

CO2 Laser Engravers with Metal Marking Compounds

CO2 lasers are not naturally suited for marking metal, as the laser wavelength does not interact effectively with metallic surfaces. However, when a metal marking compound is applied to the stainless steel surface, CO2 lasers can produce a permanent mark. The compound absorbs the laser energy and bonds to the metal, creating a black, durable mark. This method is less direct and may not offer the same resolution as fiber lasers but can be a cost-effective alternative for those who already have CO2 lasers.

Diode Laser Engravers

Diode lasers are a more recent addition to the laser engraving scene, offering a portable and relatively affordable option for hobbyists and small businesses. While traditionally less powerful than their fiber and CO2 counterparts, advanced diode laser engravers can mark stainless steel, especially when used with a marking spray or paste. The laser energy reacts with the compound to leave a permanent mark. Diode lasers are suitable for light to moderate engraving needs and can achieve impressive results with proper surface preparation and settings adjustments.

Benefits of Using Laser Engraving for Stainless Steel Flasks

Regardless of the type of laser engraver used, laser engraving offers several significant benefits for customizing stainless steel flasks:

Precision and Detail

Laser engraving allows for intricate designs and fine text to be accurately and clearly marked on the surface of stainless steel flasks. This level of detail is ideal for custom logos, detailed artwork, and personalized messages.

Durability of Markings

Engravings on stainless steel are permanent and resistant to wear, corrosion, and fading. This makes laser engraving an excellent option for items that will be used and handled frequently, such as flasks.

Efficiency and Speed

Laser engraving is a fast process that can significantly reduce production times, especially when compared to traditional engraving methods. This is particularly beneficial for businesses looking to fulfill large orders efficiently.

Flexibility

Laser engravers can adapt to various design requirements, allowing for a wide range of customization options. Whether it's a simple name, a logo, or a complex piece of artwork, laser engraving can accommodate it.

Non-Contact Process

The non-contact nature of laser engraving minimizes the risk of damaging or deforming the flask during the marking process, preserving its structural integrity and appearance.

Minimal Post-Processing

Once engraved, the stainless steel flask often requires little to no post-processing, saving time and resources in the finishing stages.

Incorporating diode laser engravers into the mix broadens the accessibility of laser engraving technology, allowing even small-scale operations or hobbyists to explore the benefits of laser-engraved stainless steel flasks. With advancements in laser technology, options for marking stainless steel continue to expand, offering solutions for various needs and budgets.

image credit: FactoryEnova - Etsy

Different Methods of Laser Engraving on Stainless Steel

Laser engraving on stainless steel can be achieved through various methods, each offering unique benefits and best suited for different applications:

Direct Laser Engraving

This method involves using a laser to directly etch the design into the stainless steel surface. It is highly precise and allows for detailed designs without the need for pre-treatment of the flask surface. However, it might require high laser power and precise control to achieve optimal results on harder stainless steel grades.

Laser Marking with a Marking Compound

Before engraving, a special marking compound (such as CerMark or LaserBond) is applied to the stainless steel surface. The laser then fuses this compound into the metal, creating a high-contrast, durable mark. This method is excellent for creating black or colored marks on stainless steel and is especially useful for barcodes or QR codes that require high readability.

Annealing Laser Engraving

This technique uses the laser to heat the surface of the stainless steel, causing an oxide layer to form, which changes the color of the metal surface without removing material. This method is ideal for applications where surface integrity must be maintained. It results in a subtle, elegant engraving but may not be as visible as direct engraving.

image credit: FactoryEnova - Etsy

Types of Stainless Steel Materials Suitable for Laser Engraving

Stainless steel is available in various grades, each with unique properties that affect its suitability for laser engraving:

Austenitic Stainless Steel (300 Series)

This is the most common type used for flasks, known for its corrosion resistance and excellent engraving results. Grades like 304 and 316 are particularly popular due to their durability and resistance to rust, making them ideal for items that will be frequently handled or exposed to the elements.

Martensitic Stainless Steel (400 Series)

These grades can also be engraved but are harder than austenitic steels, which might require adjustments in laser power and speed. They are less resistant to corrosion but offer higher strength and wear resistance.

Duplex Stainless Steel

Combining austenitic and martensitic structures, duplex stainless steel offers high strength and excellent corrosion resistance, making it suitable for high-quality flasks. However, its higher hardness can pose challenges for engraving.

image credit: DaniqueTrends - Etsy

Advantages and Disadvantages of Each Type

Austenitic Stainless Steel (300 Series)

Advantages

Excellent corrosion resistance, good for detailed engravings, widely available.

Disadvantages

Softer than martensitic and duplex steels, which might not be ideal for applications requiring extreme durability.

Martensitic Stainless Steel (400 Series)

Advantages

Higher hardness and wear resistance, suitable for more demanding applications.

Disadvantages

Requires more laser power for engraving, less corrosion resistance, making post-engraving treatments potentially necessary.

Duplex Stainless Steel

Advantages

Combines corrosion resistance with high strength, offering a balance between the two primary types.

Disadvantages

The increased hardness can make engraving more challenging, and duplex steels are generally more expensive and less commonly used for flasks.

Choosing the right stainless steel material and engraving method depends on the specific requirements of the project, including the desired aesthetic, the environment in which the item will be used, and the level of detail in the design. Each method and material type has its place, and understanding the benefits and limitations of each can help ensure the best outcome for any laser engraving project.

image credit: FactoryEnova - Etsy

Features and Benefits of Using LaserGRBL for Laser Engraving

LaserGRBL is a popular, open-source software designed for controlling laser engravers for the purpose of engraving and cutting. It's particularly favored by hobbyists and professionals who use laser engraving machine that operate on GRBL, an open-source firmware that runs on Arduino to control the movement of machines like 3D printers and laser cutters. LaserGRBL is renowned for its compatibility with Windows OS and its user-friendly interface that simplifies the laser engraving process, making it accessible even to those with limited experience in digital fabrication.

Features and Benefits of Using LaserGRBL

User-Friendly Interface

LaserGRBL is designed with a straightforward and intuitive interface, making it easy for users to navigate and operate. This accessibility is particularly beneficial for beginners in laser engraving.

Customization and Control

It offers a wide range of settings that can be adjusted according to the material being engraved and the specific requirements of the project, including laser power, speed, and the number of passes. This level of control ensures optimal results for various materials and designs.

Real-Time Preview

LaserGRBL provides a real-time preview of the engraving or cutting path. This feature allows users to verify the accuracy of the design and its alignment on the material before starting the engraving process, reducing errors and material wastage.

Support for Multiple File Formats

The software supports various file formats, including JPG, BMP, PNG, and G-code, facilitating the import and conversion of different types of designs and images for engraving.

Cost-Effectiveness

As an open-source platform, LaserGRBL is freely available to download and use, offering a cost-effective solution for laser engraving needs without compromising on functionality.

Active Community Support

Being open-source, LaserGRBL is supported by a vibrant community of users and developers. This community contributes to regular updates, improvements, and a wealth of knowledge and troubleshooting advice readily available to all users.

Comparison with Other Laser Engraving Software

When compared to other laser engraving software options, such as LightBurn, LaserGRBL offers a unique set of advantages and limitations:

Platform Compatibility

Unlike LaserGRBL, which is exclusive to Windows, some alternatives like LightBurn provide cross-platform support, including macOS and Linux. This broader compatibility can be a decisive factor for users operating on different operating systems.

Ease of Use

LaserGRBL's interface is particularly suited to those new to laser engraving, offering a less steep learning curve than some of its competitors. However, software like LightBurn, while more complex, offers advanced features and greater control over the engraving process, catering to both beginners and experienced users.

Features and Functionality

While LaserGRBL covers the basics efficiently, other software solutions may offer a wider array of advanced features, such as more sophisticated image editing tools, support for additional laser cutter models, and enhanced project management capabilities.

Cost: The fact that LaserGRBL is free makes it an attractive option for individuals or small businesses on a tight budget. In contrast, some alternatives require a purchase or subscription, though they may offer additional features and support that justify the expense.

image credit: CustomizeLaserWorks - Etsy

How to Laser Engrave Stainless Steel Flask

Step 1, power on the machine.

Step 2, adjust the focus according to the engraved item.

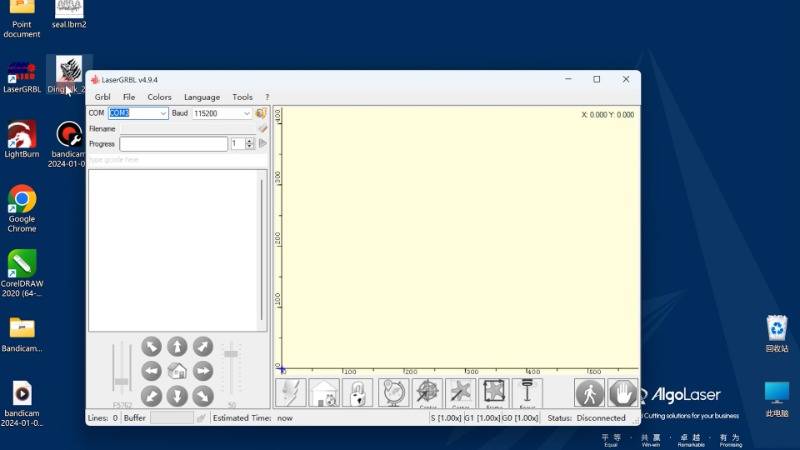

Step 3, open the LaserRGBL.

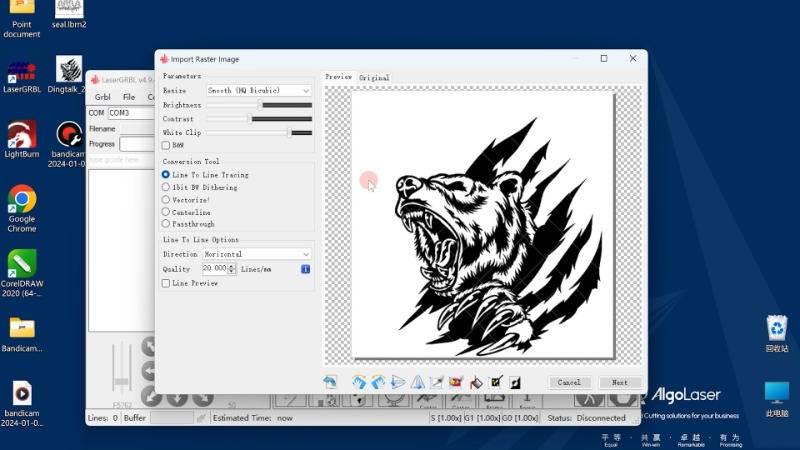

Drag the prepared pattern into the workspace.

Step 4, set the engraving parameters as required.

Wait for the image processing to complete.

Step 5,Click on the connection icon.

Click “Frame”button to determine the processing area.

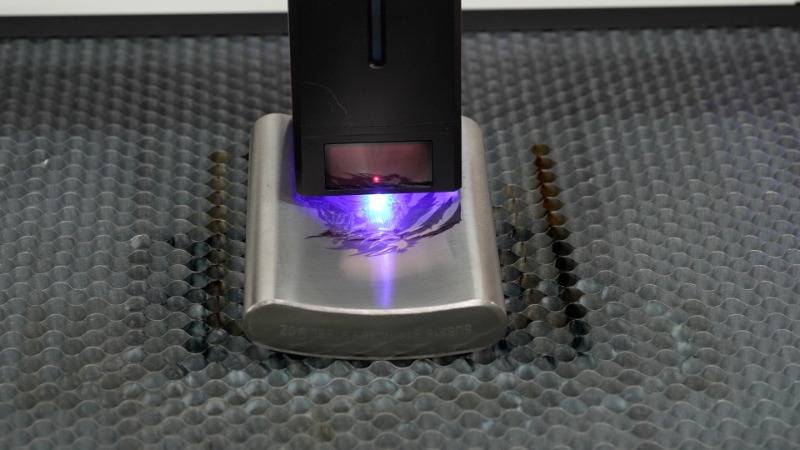

Step 6, click “Start”.

Illustrative Examples of High-Quality Laser Engraved Stainless Steel Flask Products

1. Precision-Engraved Commemorative Flask

A stainless steel flask featuring intricately detailed, laser-engraved commemorative dates or events. Stands out for its precise detailing and ability to capture fine text and images, making it a perfect keepsake or gift.

2. Personalized Wedding Party Flasks

These flasks come engraved with the wedding date, names, or a special message for each member of the wedding party. They're notable for their personalized touch and the use of high-contrast engraving for lasting visibility.

image credit: ImprintandImpress - Etsy

3. Corporate Branded Flasks

Designed for corporate events or as high-end promotional items, these flasks feature laser-engraved company logos or slogans. They are distinguished by their professional appearance and the precision of the brand's logo reproduction.

4. Adventure-Themed Flasks

These flasks showcase detailed landscapes, maps, or adventure-related quotes, appealing to outdoor enthusiasts. They stand out due to their unique thematic engravings that are both inspirational and aesthetically pleasing.

image credit: Mintsignia - Etsy

5. Limited Edition Artist Series Flasks

A series of flasks featuring artwork from various artists, laser-engraved into the stainless steel. These are unique for their artistry and the collaboration with artists, making each flask a collectible item.

6. Monogrammed Classic Flasks

Elegantly designed with personalized monograms or initials. These flasks are noted for their timeless appeal and the deep engraving that offers a tactile experience as well as visual elegance.

image credit: DaniqueTrends - Etsy

7. Sports Team Flasks

Featuring the logos or mascots of favorite sports teams, these are perfect for fans wishing to show their support. They're unique for their vibrant, fan-focused designs and the precision with which team emblems are reproduced.

8. Interactive QR Code Flasks

Engraved with QR codes that link to a personal message, video, or website, these flasks merge traditional gift-giving with digital interactivity. They stand out for incorporating technology in a meaningful, personalized way.

image credit: DZHatsandCrafts - Etsy

9. Fitness Inspirational Quotes Flasks

Aimed at fitness enthusiasts, these flasks carry motivational quotes or fitness challenges. They're notable for their role in inspiring daily hydration and fitness goals, with clear, durable engravings that endure daily wear and tear.

10. Culinary Cocktail Recipe Flasks

These feature laser-engraved cocktail recipes or culinary quotes, ideal for culinary enthusiasts. They stand out for their utility and creativity, offering both aesthetic appeal and practical value to those who enjoy mixing drinks or cooking.

image credit: FactoryEnova - Etsy

FAQs Of Laser Engraving Stainless Steel Flask

1. Can any type of stainless steel flask be laser engraved?

Yes, most stainless steel flasks can be laser engraved. However, the quality of the engraving can vary depending on the alloy composition and the coating of the flask. It's important to check with the manufacturer or perform a test engraving if you're unsure about the flask's suitability.

2. What type of laser engraver is best for stainless steel?

Diode laser engravers are generally considered the best for engraving stainless steel due to their ability to produce high-contrast, precise engravings.

3. What settings should I use for engraving stainless steel?

The optimal settings can vary depending on your laser engraver and the specific stainless steel flask. Generally, a high power and slow speed setting are recommended for a deep and clear engraving. Always refer to your laser engraver's manual and perform test engravings to determine the best settings.

4. How do I maintain my laser engraved stainless steel flask?

Laser-engraved stainless steel flasks can be maintained with regular cleaning using mild soap and water. Avoid abrasive cleaners that can damage the engraving. If the flask has a special coating, follow the manufacturer's care instructions to avoid damaging it.

5. Is laser engraving stainless steel expensive?

The cost of laser engraving can vary based on the complexity of the design, the size of the engraving, and the quantity of flasks being engraved. While investing in your own laser engraver can be costly upfront, the actual cost per engraving is relatively low, especially for bulk orders.

6. Can I remove or correct an engraving mistake on a stainless steel flask?

Removing or correcting an engraving on stainless steel is challenging due to the permanence of the laser marking. In some cases, the engraved area can be mechanically polished to remove the top layer of metal, but this may not completely erase the engraving and can alter the flask's finish.

7. Are there any limitations to what I can engrave on a stainless steel flask?

The primary limitations are related to the size of the engraving area and the complexity of the design. Fine details may not always translate well to engraving, especially on smaller flasks. Copyrighted material or offensive content should also be avoided unless you have permission to use the design.

8. How long does laser engraving on a stainless steel flask last?

Laser engraving is a permanent process that modifies the surface of the stainless steel. It should last the lifetime of the flask under normal use and care conditions.

9. Can laser engraving on stainless steel flasks be done in color?

Traditional laser engraving on stainless steel results in a monochrome finish, typically in shades of black or gray, depending on the material and settings. However, some specialized laser processes can induce colors on stainless steel, but these are less common and depend on very specific material properties and laser parameters.

image credit: MemoriesMadeCustom - Etsy

Conclusion

Tips for First-Timers

Start with a simple design to understand how your machine handles stainless steel.

Always perform a test run on a similar material to fine-tune your settings.

Clean the flask thoroughly before engraving to ensure the laser interacts directly with the metal surface for a clean, clear engraving.

Troubleshooting Common Issues

Faint Engraving: Increase the power or decrease the speed of your laser engraver. Also, ensure the flask's surface is clean and free of coatings.

Inconsistent Engraving: Check the focus of your laser engraver and ensure the flask is flat and securely positioned.

Design Misalignment

Double-check the alignment of your flask before starting the engraving process and use the preview feature if your software offers it.

Laser engraving stainless steel flasks can be a rewarding process, allowing for high levels of customization and creating unique, personalized items. With practice and attention to detail, even beginners can achieve professional-looking results.

Free SVG & Gcode Files for Laser Engraving & Cutting can be found here, wich you can import into our laser cutters directly.

- Choosing a selection results in a full page refresh.