Laser and Material Interaction - Plasma Effect

What is Plasma?

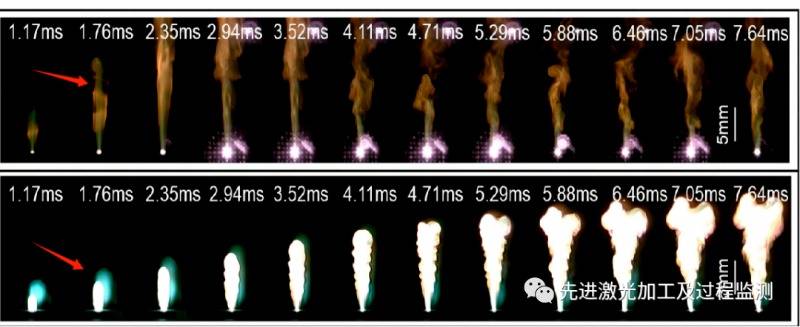

In laser welding, a flame-like flow is often accompanied (jets of flames, yellow light, blue light, purple light are all present), which is commonly referred to as plasma.

Plasma Definition

Plasma is a gaseous mixture of free electrons, ions, and electrically neutral particles (atoms, molecules, and radicals) that is produced during the laser welding process by the vaporization of metal materials due to laser radiation. This type of plasma, generated by light, is known as photo-induced plasma. The main components of photo-induced plasma are metal vapors, free electrons, ions, and electrically neutral particles.

Plasma Formation Process

During the laser ablation of the material surface, plasma is generated when the laser power density reaches a certain threshold. The specific microscopic mechanism can be divided into two steps:

Step One

When the laser irradiates the metal surface, electrons near the surface absorb photons through inverse bremsstrahlung recombination, and these energized electrons transfer their absorbed energy to the metal lattice through interactions with phonons. The process of electrons being heated and the energy transfer process within the lattice are both completed within a few picoseconds, resulting in a rapid increase in both electron temperature and lattice vibrational temperature, ultimately leading to the breaking of bonds within the lattice and exhibiting phenomena such as metal vaporization and explosion.

Step Two

The initial products of ablation and the laser interact near the surface of the material, causing the evaporated substance to continue heating and ionizing. This process includes three effects: free electrons absorbing the energy of laser radiation, continuously colliding with atoms and molecules causing ionization, thereby generating new free electrons that continue to collide and ionize in a cyclic manner, triggering an avalanche of ionization; charge carrying ions colliding with atoms and molecules, causing ionization; and excited state atoms and molecular groups undergoing photoionization.

In summary

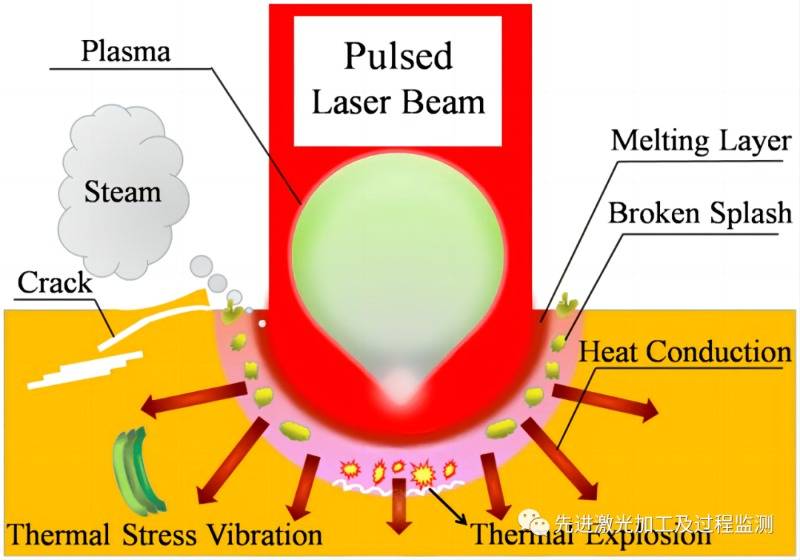

During the laser deep penetration welding process, when the energy density of the incident laser is sufficiently high, it can vaporize the metal and form a keyhole in the melt pool. At the same time, metal vapor ejected from the metal surface and the keyhole, as well as some free electrons from the protective gas, are accelerated by absorbing laser energy, increasing their kinetic energy. This causes them to collide with vapor particles and protective gas, triggering a chain reaction, thereby ionizing extensively. As a result, a dense plasma is formed above the keyhole, which significantly affects the laser welding process.

Characteristics of Plasma

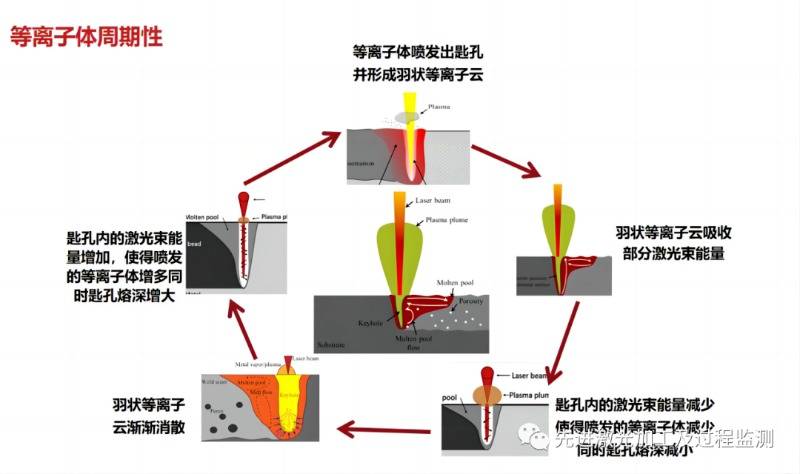

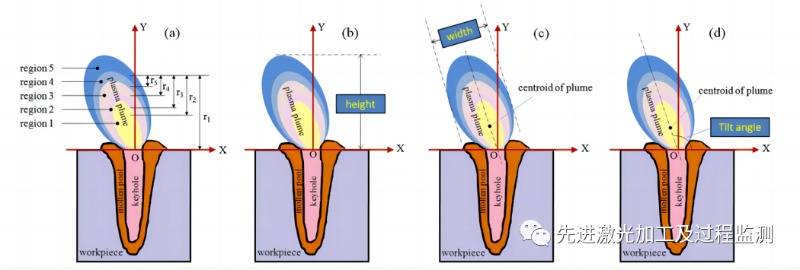

Periodic Characteristics of Plasma

As the laser outputs and irradiates the surface of the material, it generates plasma. When the density of the photo-induced plasma becomes too high, it significantly increases the loss of laser energy, causing the energy density reaching the surface of the workpiece to weaken. This results in a decreasing amount of metal vapor produced, and the plasma gradually disappears. At this point, the laser can directly irradiate the surface of the workpiece again, recreating a large amount of metal vapor, and the intensity of the plasma gradually increases, once again shielding the incident laser. This cycle repeats, with the intensity of the plasma undergoing periodic changes. Through spectral analysis and high-speed camera observation, the frequency of plasma intensity oscillations is found to be in the order of several hundred Hertz. This also leads to periodic serrated fluctuations in laser welding, which is particularly noteworthy in welding thin plates (laser modulation, CW modulated, is one direction for solving this problem).

The Role of Plasma in Energy Transfer

In high-power laser welding processes, as the high-energy density laser beam continues to output, energy is transferred to the surface of the workpiece, continuously melting and evaporating the metal material. The vapor cloud rapidly jets upwards from the keyhole, and upon reaching ionization conditions, it quickly ionizes to form plasma, predominantly composed of metal vapor plasma. Once formed, the plasma will reflect, scatter, and absorb the incident light beam through refraction and radiative absorption, creating a shielding effect on the laser beam. This affects the coupling of laser energy with the workpiece, influencing the melt depth, the formation of pores, and the composition of the weld seam, ultimately directly affecting the quality of laser welding and the reliability of the process.

Plasma Applications

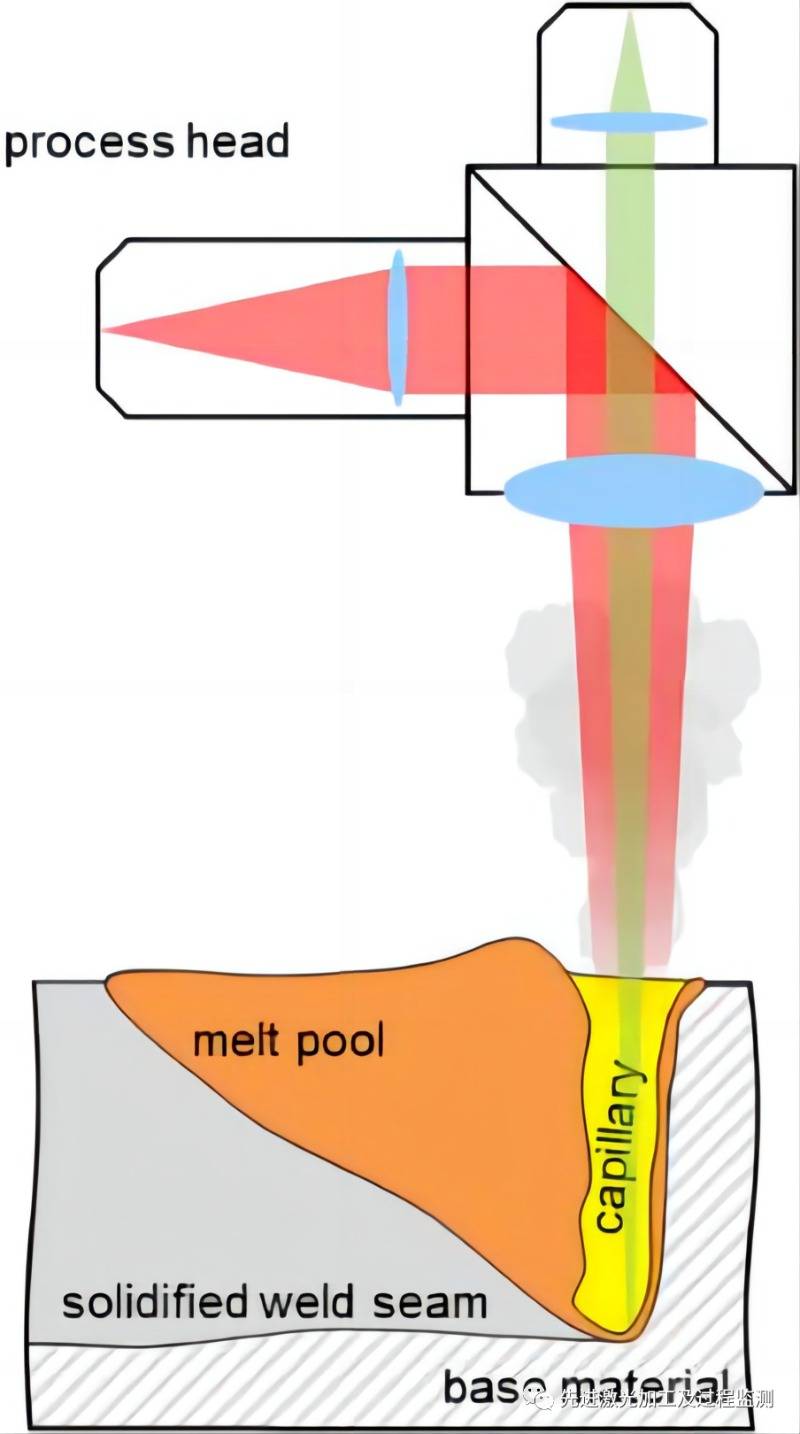

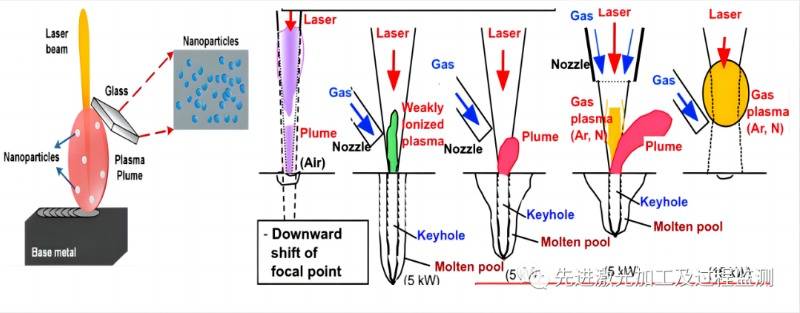

Refraction of Laser by Plasma

Plasma acts as a lens positioned between the material and the laser, leading to what can be summarized as the negative lens effect of plasma: air is an optically denser medium, whereas plasma is an optically rarer medium. This results in the divergence of the laser beam, worsening the laser's focusing ability and dispersing the laser, thereby reducing the energy density. When the incident laser beam passes through the plasma, it can also cause a change in the direction of the laser beam propagation. The deflection angle is related to the gradient of the plasma's electron density and the length of the plasma, leading to an uneven energy density of the laser reaching the material surface, with energy fluctuations changing in accordance with plasma fluctuations.

As illustrated, the more plasma accumulates, the greater the impact on laser welding. The more the laser diverges, the lower the energy density, leading to a sudden decrease in penetration depth. Therefore, common issues like lack of penetration in welding are often due to not using shielding gas, resulting in poor weld quality.

Absorption of Laser by Plasma

The absorption of laser energy by plasma increases its temperature and ionization level. The absorption process can be divided into normal absorption and anomalous absorption. Normal absorption, also known as inverse bremsstrahlung absorption, refers to electrons being excited by the laser's electric field to oscillate at high frequencies, colliding with surrounding particles (mainly ions), and transferring energy to each other, thereby increasing the temperature and ionization level of the plasma. Anomalous absorption, on the other hand, refers to a series of non-collision mechanisms that convert laser energy into plasma wave energy, which is then transformed into plasma thermal energy through different dissipation mechanisms and dissipated into the air.

Because of the absorption of laser by plasma, only a portion of the incident laser energy can penetrate the plasma and reach the surface of the workpiece. This increases the energy transmission loss along the external optical path (from the laser OBH to the material surface), reducing the laser energy density. The overall absorption rate decreases, and if the window is at the upper boundary, it can easily lead to lack of fusion, especially with highly reflective materials (like aluminum and copper).

How to Suppress Plasma Effect?

The main factors influencing the plasma's refractive index, negative lens effect, and absorption rate include:

1. Laser Wavelength

The ignition and maintenance thresholds of plasma are directly proportional to the square of the wavelength. Short-wavelength lasers (such as blue and green light) have shorter plasma maintenance times, making the process more stable.

2. Laser Power Density

The electron temperature and density of the plasma increase with the laser power density. Excessively high power density is a primary cause of plasma instability. Composite heat sources (e.g., ring-shaped spots, fiber semiconductor composites, laser-arc composites) can achieve controlled energy distribution of the heat source. Compared to single fiber laser welding, the impact of plasma effects is smaller, making the welding process more stable.

3. Spot Size

Smaller spot diameters increase the ignition and maintenance values of plasma (wobble welding can avoid this).

4. Material Properties

The density and ionization energy of materials greatly affect the plasma. Metals with lower ionization energy and higher reflectivity are more likely to be affected by plasma effects, impacting deep penetration welding stability.

5. Environmental Gas and Pressure

It is generally believed that gases with good thermal conductivity and high ionization energy have higher plasma ignition and maintenance thresholds. Lower environmental air pressure leads to lower electron temperature, electron density, and plasma center height. Under vacuum or negative pressure conditions, laser deep penetration welding is more stable than at atmospheric pressure.

6. Gas Flow Rate

Increasing the flow rate of the environmental gas reduces the volume of the plasma, thereby decreasing its absorption rate of the laser and effectively reducing the plasma's impact on the deep penetration welding process. However, excessively high gas flow rates can cause fluctuations on the surface of the welding pool and splashing of molten metal, as well as cracks and surface roughness due to rapid cooling.

7. Welding Speed

The center temperature of the plasma increases as the welding speed decreases. Lower welding speeds make it easier to produce plasma and more unstable. Increasing the welding speed to a certain extent can also improve the stability of the welding process.

Approaches to Suppressing Plasma Effects

1. Wobble Welding

The laser processing head sways left and right along the welding direction. Before the formation of plasma after the keyhole appears, the laser spot is momentarily moved to the rear edge of the melt pool or another location to avoid the influence of plasma on the optical path transmission.

2. Pulsed Laser Welding

Adjusting the pulse and frequency of the laser so that the laser's irradiation time is less than the formation time of the plasma. This ensures that the laser always hits during the dissipation phase of the plasma formation-dissipation cycle, avoiding interference with the optical path transmission by the plasma.

3. Low-Pressure Welding

Employing reduced pressure welding, when the air pressure is below a certain level, the density of metal vapor on the material surface and inside the keyhole is low, causing the plasma to disappear.

4. Blowing Protective Gas

One method involves using auxiliary gas to disperse the plasma, and another uses gases with good thermal conductivity and high ionization energy to suppress the ionization of the environmental gas and condense the metal ion vapor. A double-layer nozzle coaxial with the main blow can be used, where the outer nozzle is angled to the horizontal direction, using the radial component of the outer airflow to blow the plasma sideways. A straight tube nozzle can also be used, aimed directly at the plasma and blowing gas laterally along the welding direction.

This method requires strict control over the positioning accuracy of the side-blowing nozzle and the airflow volume. Among the many control methods, controlling plasma through airflow is relatively flexible and simple. Therefore, side-blowing protective gas is a widely adopted method in laser deep penetration welding.

Free SVG & Gcode Files for Laser Engraving & Cutting can be found here, wich you can import into our laser cutters directly.

- Choosing a selection results in a full page refresh.