How Delta Engraves on MDF with LaserGRBL

Laser engraving has revolutionized the way we personalize and embellish various materials in modern crafting and manufacturing. Due to its affordability and versatility, Medium-Density Fiberboard (MDF) stands out as a popular choice. With the combination of diode laser engraving machines and advanced software like LaserGRBL, MDF engraving has become more precise and intricate. The importance of Delta engravers and LaserGRBL software will be emphasized during our exploration of MDF engraving.

Types of Laser Engraves on MDF Materials

When it comes to engraving on Medium-Density Fiberboard (MDF) materials, choosing the right type of laser is crucial to achieving optimal results. MDF is a popular choice for engraving due to its affordability, uniform density, and smooth surface, making it suitable for a wide range of applications including signage, artwork, and decorative items. Let's explore the types of lasers commonly used for engraving on MDF:

CO2 Laser Engraver

CO2 lasers are one of the most common types of lasers used for engraving on various materials, including MDF. These lasers generate a beam of infrared light with a wavelength of around 10,600 nanometers, which is well-absorbed by the organic compounds present in MDF. CO2 lasers are known for their versatility and ability to produce high-quality engravings with precision and speed. They can cut through MDF with ease and are capable of creating intricate designs and detailed patterns.

Fiber Laser Engraver

Fiber lasers are another type of laser commonly used for engraving on MDF. Unlike CO2 lasers, fiber lasers generate a beam of light using a fiber-optic cable doped with rare-earth elements such as erbium, ytterbium, or neodymium. These lasers operate at a shorter wavelength (typically around 1,064 nanometers) and are well-suited for engraving metals and some plastics. While fiber lasers can engrave MDF, they are not as commonly used for this purpose compared to CO2 lasers.

Diode Laser Engraver

Diode lasers have gained popularity in recent years for their affordability, compact size, and ease of use. These lasers generate a coherent beam of light through the use of semiconductor diodes, making them highly efficient and reliable. Diode lasers are ideal for engraving on MDF due to their ability to produce precise and detailed engravings with minimal heat affected zones. They are particularly well-suited for engraving small objects and intricate designs on MDF surfaces.

Each type of laser has its advantages and limitations when it comes to engraving on MDF materials. CO2 lasers are known for their versatility and ability to produce high-quality engravings, while fiber lasers are better suited for engraving metals and some plastics. Diode lasers offer a cost-effective solution for engraving on MDF, making them popular among hobbyists, artists, and small businesses. Ultimately, the choice of laser depends on factors such as budget, application requirements, and desired engraving quality.

The Role of LaserGRBL in Laser Engraves on MDF

LaserGRBL plays a pivotal role in the process of laser engraving on Medium-Density Fiberboard (MDF), acting as the bridge between the user and the laser engraving machine. This advanced software provides users with the tools and functionalities needed to achieve precise and high-quality engravings on MDF surfaces. Let's explore the key roles of LaserGRBL in laser engraving on MDF:

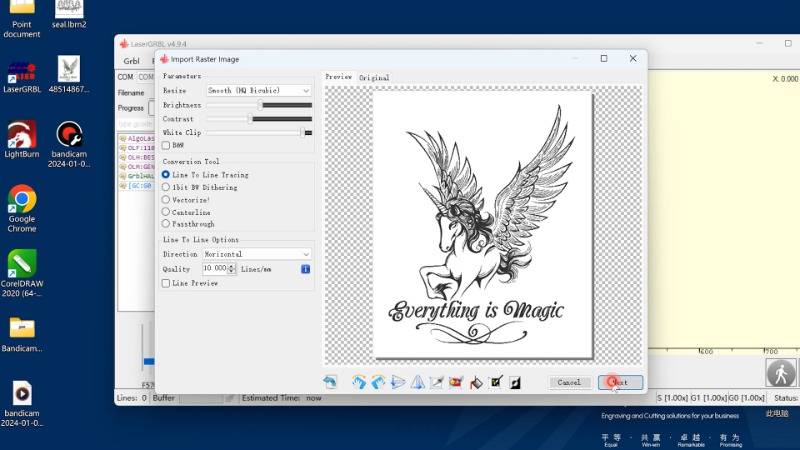

Design Upload and Editing

One of the primary functions of LaserGRBL is to facilitate the upload and editing of design files for engraving on MDF. Users can import designs in various file formats, including vector graphics (such as SVG, DXF, and AI) and raster images (such as BMP, JPG, and PNG). LaserGRBL allows users to adjust the size, position, and orientation of the design within the workspace, ensuring optimal placement on the MDF surface.

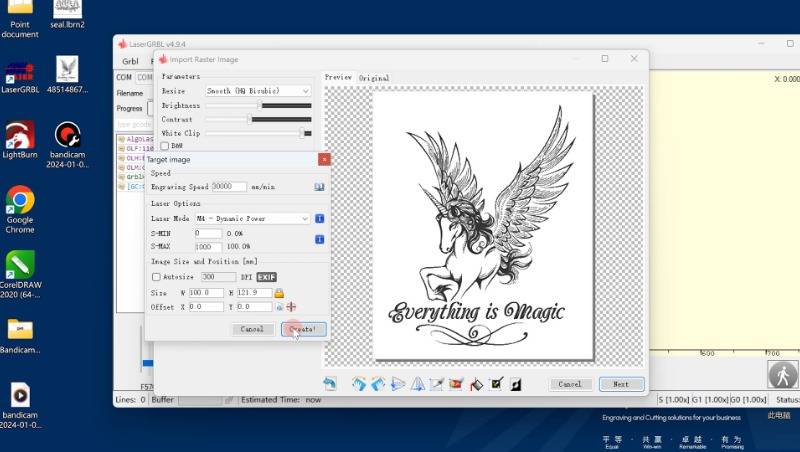

Engraving Parameters Adjustment

LaserGRBL provides users with precise control over the engraving process by allowing them to adjust various parameters such as power, speed, and frequency. These parameters determine the intensity and depth of the laser beam, as well as the speed at which it moves across the MDF surface. By fine-tuning these settings, users can achieve desired engraving results, whether it's deep engraving for a dramatic effect or shallow engraving for a subtle finish.

Real-Time Preview and Simulation

LaserGRBL offers users the ability to preview and simulate the engraving process in real-time before executing the job on the MDF material. This feature allows users to visualize how the design will appear on the finished product and make any necessary adjustments to optimize the engraving quality. By simulating the engraving process, users can identify potential issues such as overlapping paths or uneven engraving depths and address them before starting the job.

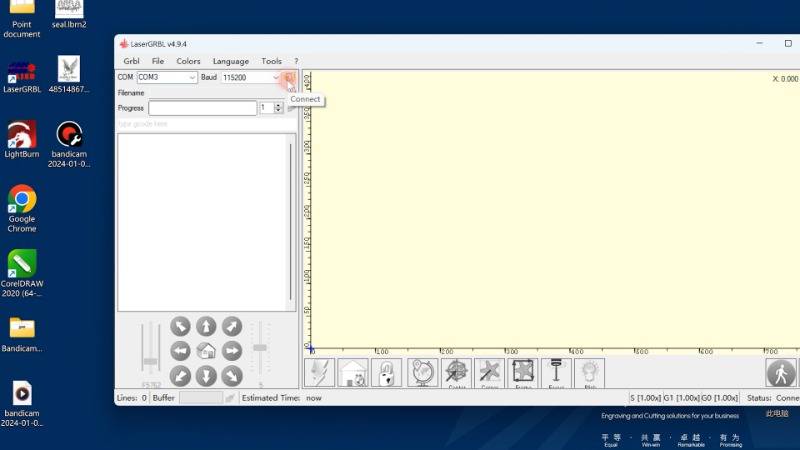

Laser Control and Monitoring

LaserGRBL enables users to control the laser engraving machine directly from the software interface, providing them with seamless integration and ease of operation. Users can start, pause, and stop the engraving process with the click of a button, as well as adjust laser power and speed settings on the fly. Additionally, LaserGRBL provides real-time monitoring of the engraving progress, allowing users to track the job status and ensure consistent and accurate results.

Compatibility and Customization

LaserGRBL is compatible with a wide range of laser engraving machines, including those equipped with diode lasers commonly used for engraving on MDF. The software offers extensive customization options, allowing users to configure settings and parameters to suit their specific engraving needs. Whether it's adjusting laser power for different types of MDF or optimizing engraving speed for intricate designs, LaserGRBL provides users with the flexibility to achieve optimal results.

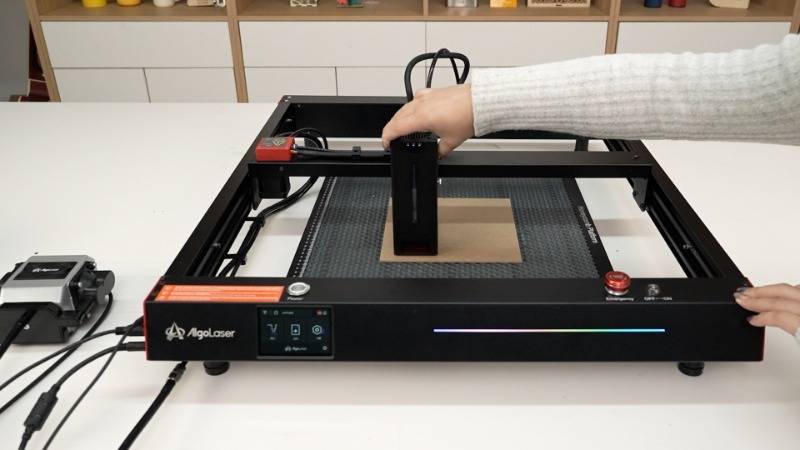

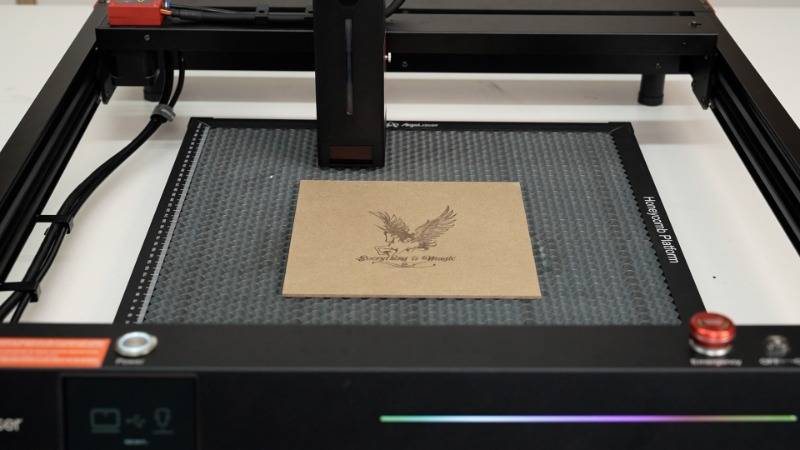

How Delta Engraves on MDF with LaserGRBL by AlgoLaser Delta

Delta engraving machines by AlgoLaser represent the pinnacle of diode laser engraving technology, offering unparalleled precision and efficiency in engraving on Medium-Density Fiberboard (MDF) surfaces. When combined with LaserGRBL, these cutting-edge machines provide users with a seamless and intuitive engraving experience. Let's delve into how Delta engraves on MDF with LaserGRBL:

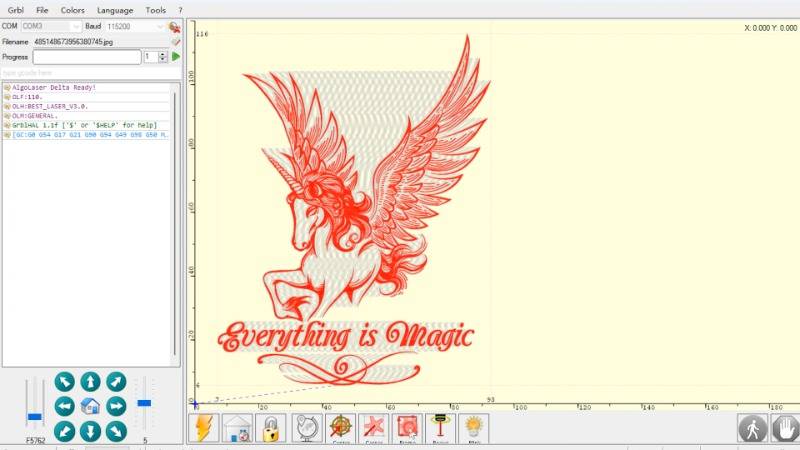

Step 1, open the LaserRGBL, click on the connection icon. Drag the prepared pattern into the workspace.

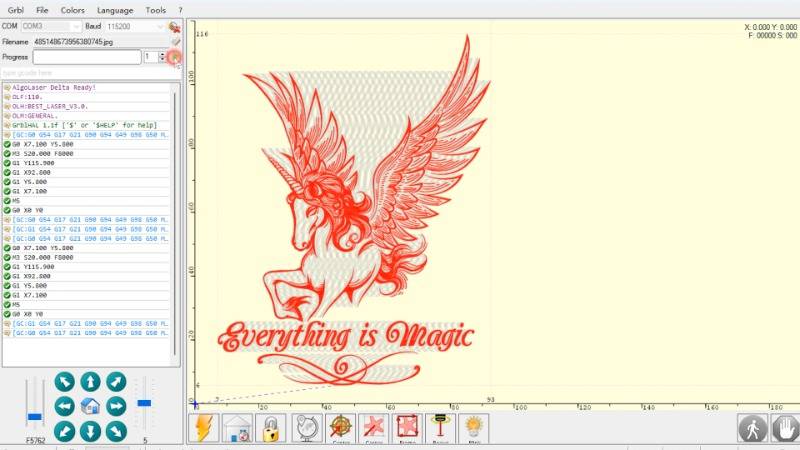

Step 2, set the engraving parameters as required. Wait for the image processing to complete.

Step 3, click "Frame" button to determine the processing area.

Step 4, click "Start".

FAQs About Laser Engraves on MDF

Can MDF withstand laser engraving?

Yes, MDF (Medium-Density Fiberboard) is well-suited for laser engraving. Its composition of wood fibers and resin allows it to be effectively engraved by laser engraving machines without significant damage to the material.

What are the recommended settings for MDF engraving with a laser engraver?

Recommended settings typically include using low to medium power levels (around 10-30% power) and moderate speed settings. These settings help to achieve clean and precise engravings on MDF without burning or scorching the material.

How deep can you engrave into MDF with a laser engraver?

The depth of engraving into MDF with a laser engraver can vary depending on factors such as the power of the laser, the speed of engraving, and the desired outcome. Generally, laser engravers can achieve depths ranging from 0.1mm to 1mm into the surface of MDF.

Is MDF safe for laser engraving in terms of fumes?

MDF produces minimal fumes during laser engraving, especially when compared to other materials like plastics. However, it's still advisable to work in a well-ventilated area or use a fume extraction system to remove any smoke or odor generated during the engraving process.

How should MDF be prepared for laser engraving?

Before laser engraving, it's essential to ensure that the surface of the MDF is clean and free from any dust or debris. Additionally, applying a thin layer of masking tape or engraving spray can help protect the surface and improve the quality of the engraving.

Can you color laser-engraved MDF?

Yes, laser-engraved MDF can be colored using various methods. One common method is to apply wood stains or dyes to the engraved areas, which can enhance the contrast and appearance of the engraving. Additionally, painting or using markers on the engraved surface can also add color and detail to the design.

Conclusion

From the versatility of diode lasers to the seamless integration provided by LaserGRBL, and the precision and efficiency of Delta engravers, it's evident that laser engraving on MDF offers endless possibilities for creativity and craftsmanship. Whether you're a hobbyist, artist, or professional, laser engraving on MDF allows you to unleash your imagination and bring your designs to life with unparalleled accuracy and detail.

- Choosing a selection results in a full page refresh.