How Alpha 10W Cutting 3mm Acrylic to make earrings

Types of Laser Cutting on Acrylic Materials

Laser cutting is a versatile and precise method for shaping acrylic materials into various designs and forms, including earrings. Here are the different types of laser cutting techniques commonly used on acrylic materials:

Vector Cutting

Description: Vector cutting is a process where the laser beam follows a vector path to cut through the material along the outline of the design. It cuts completely through the material, creating precise shapes with clean edges.

Applications: Vector cutting is ideal for creating intricate shapes and designs in acrylic earrings. It allows for precise cutting of outlines, curves, and fine details.

Raster Engraving

Description: Raster engraving is a process where the laser beam moves back and forth across the surface of the material, removing a thin layer of material to create a textured or engraved effect. It does not cut all the way through the material but instead engraves the surface.

Applications: Raster engraving is commonly used to add decorative patterns, textures, or text to acrylic earrings. It can create intricate designs with varying depths and shades of engraving.

Vector Engraving

Description: Vector engraving is similar to vector cutting but involves engraving the surface of the material instead of cutting through it. The laser beam follows a vector path to remove material from the surface, creating shallow indentations or markings.

Applications: Vector engraving is suitable for creating outlines, scoring, or etching on the surface of acrylic earrings. It can be used to add decorative elements or highlight details without cutting through the material.

Combined Cutting and Engraving

Description: This technique combines vector cutting and raster engraving in a single design. The laser is programmed to cut through certain areas of the material while engraving others, allowing for intricate designs with both cut-out shapes and engraved details.

Applications: Combined cutting and engraving are used to create acrylic earrings with complex designs that feature both cut-out elements and engraved patterns or textures.

Kerf Adjustment Cutting

Description: Kerf adjustment cutting involves adjusting the width of the laser beam to compensate for the material removed during cutting. By controlling the kerf (width of the cut), this technique ensures precise fitting of interlocking parts and reduces material wastage.

Applications: Kerf adjustment cutting is useful for creating acrylic earrings with interlocking components or assemblies, such as puzzle earrings or layered designs. It ensures a tight fit between the pieces and minimizes gaps or discrepancies in the final product.

Each type of laser cutting technique offers unique advantages and applications for creating acrylic earrings with intricate designs and precise detailing. By understanding the characteristics of each technique, jewelry designers can choose the most suitable method to achieve their desired results.

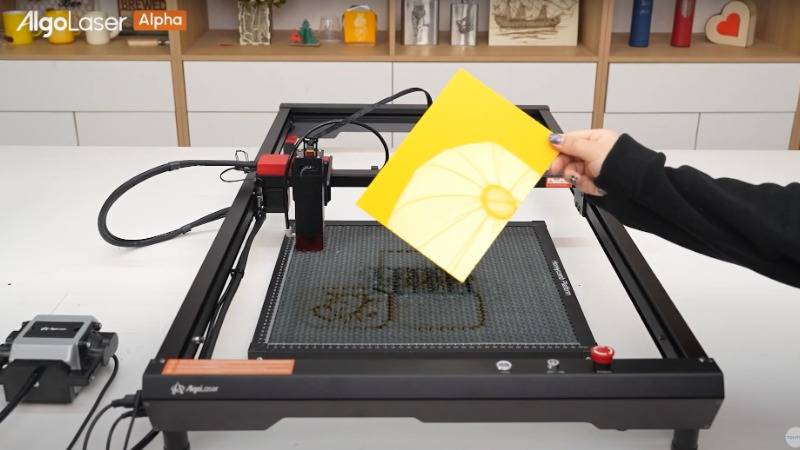

How To Laser Engrave and Cut on Acrylic with the Alpha 10W Laser Engraver

Here's a detailed guide on how to laser engrave and cut on acrylic using the Alpha 10W Laser Engraver:

Preparation

Ensure the Alpha 10W Laser Engraver is set up in a well-ventilated area with proper ventilation to remove any fumes generated during the engraving and cutting process.

Put on appropriate personal protective equipment (PPE) such as safety glasses and gloves to protect against laser radiation and hot materials.

Preparing the Acrylic Material

Start by selecting a suitable acrylic sheet for your earrings. Acrylic sheets typically come in various colors and thicknesses, with 3mm thickness being commonly used for earrings.

Clean the surface of the acrylic sheet to remove any dust, dirt, or debris that could interfere with the engraving and cutting process. Use a mild soap and water solution or acrylic cleaner for best results.

Setting Up the AlgoLaser Alpha 10W

Power on the AlgoLaser Alpha 10W Laser Engraver and ensure it is properly calibrated and aligned.

Open the LightBurn software on your computer and connect it to the Alpha 10W Laser Engraver.

Import or create the design you want to engrave and cut on the acrylic sheet. Ensure the design fits within the dimensions of the acrylic sheet and is properly aligned.

Adjusting Cutting Parameters

Before starting the engraving and cutting process, adjust the cutting parameters in the LightBurn software to suit the properties of the acrylic material.

Set the appropriate laser power, cutting speed, and frequency settings based on the thickness and type of acrylic being used. It's recommended to start with lower power and speed settings and gradually increase them until the desired results are achieved.

Executing the Engraving and Cutting Process

Once the cutting parameters are adjusted, place the acrylic sheet onto the bed of the AlgoLaser Alpha 10W Laser Engraver and secure it in place using clamps or tape.

Start the engraving and cutting process by sending the design to the laser engraver through the LightBurn software. Ensure the laser head is positioned correctly over the starting point of the design.

Monitor the engraving and cutting process closely to ensure the laser is cutting through the acrylic material smoothly and accurately. Make any necessary adjustments to the cutting parameters if needed.

Post-Processing

Once the engraving and cutting process is complete, carefully remove the acrylic sheet from the laser engraver bed.

Clean the engraved and cut acrylic earrings with a mild soap and water solution to remove any residue or debris.

If desired, you can further polish the edges of the earrings using a flame polisher or sandpaper to achieve a smooth and professional finish.

Safety Precautions

Always follow proper safety precautions when operating the Alpha 10W Laser Engraver, including wearing appropriate PPE and ensuring proper ventilation in the workspace.

Never leave the laser engraver unattended during operation, and always follow manufacturer guidelines and recommendations for safe use.

By following these steps, you can effectively laser engrave and cut acrylic to create customized and intricately designed earrings using the Alpha 10W Laser Engraver.

FAQs About Laser Cut on Acrylic

What thickness of acrylic is suitable for laser cutting earrings?

Acrylic sheets typically come in various thicknesses, ranging from 1mm to 10mm or more. For earrings, a thickness of around 3mm is commonly used as it provides sufficient rigidity while still allowing for intricate designs to be cut.

How does laser cutting affect the edges of acrylic earrings?

Laser cutting produces clean, precise edges on acrylic, resulting in a smooth and polished finish. However, it's essential to adjust the laser parameters properly to avoid overheating, which can cause melting or charring along the edges.

Can laser cutting acrylic produce sharp corners and intricate designs?

Yes, laser cutting is capable of creating sharp corners and intricate designs with high precision. The focused laser beam can cut through acrylic with extreme accuracy, allowing for the creation of detailed shapes and patterns in earrings.

Is it possible to achieve different colors or effects on acrylic earrings through laser engraving?

While laser cutting removes material to create shapes, laser engraving selectively burns the surface of the acrylic to produce different colors and effects. By adjusting the laser power and speed settings, it's possible to achieve variations in color, depth, and texture on acrylic earrings.

How durable are acrylic earrings made with laser cutting?

Acrylic earrings made with laser cutting are durable and lightweight. Acrylic is known for its strength and resilience, making it suitable for everyday wear. However, care should be taken to avoid excessive bending or scratching, as acrylic can be prone to surface damage.

Are there any safety precautions to consider when laser cutting acrylic for earrings?

Yes, safety precautions are essential when working with a laser cutter. Proper ventilation is necessary to remove fumes and gases produced during the cutting process. Additionally, wearing protective eyewear and gloves can help prevent exposure to laser radiation and hot materials.

Can laser cutting acrylic produce toxic fumes?

When acrylic is cut with a laser, it can produce fumes that may be harmful if inhaled. It's essential to ensure adequate ventilation in the workspace to remove these fumes and protect against potential health risks. Using a laser cutter with an exhaust system can help mitigate this issue.

How can I clean and finish laser-cut acrylic earrings for a professional look?

To clean laser-cut acrylic earrings, use a mild soap and water solution or acrylic cleaner to remove any dirt or residue. For a polished finish, you can also use a polishing compound or a flame polisher to smooth out any rough edges and enhance the clarity of the acrylic surface.

Each type of laser cutting technique offers unique advantages and applications for creating acrylic earrings with intricate designs and precise detailing. By understanding the characteristics of each technique, jewelry designers can choose the most suitable method to achieve their desired results.

Free SVG & Gcode Files for Laser Engraving & Cutting can be found here, wich you can import into our laser cutters directly.

- Choosing a selection results in a full page refresh.