The Power of AlgoLaser AlgoOS: Revolutionizing the MK2 Laser Engraver

The AlgoLaser MK2 laser engraver is a cutting-edge device designed to bring precision, efficiency, and versatility to the world of laser engraving and cutting. At the heart of this powerful tool is AlgoOS, a sophisticated operating system that streamlines the engraving process and offers a plethora of features tailored to meet the needs of both novice and experienced users. We will delve into the various aspects of the AlgoOS system and how it enhances the capabilities of the AlgoLaser MK2.

Wood Relief Engraving with AlgoLaser MK2

Wood relief engraving is one of the most popular applications for laser engravers. It involves carving intricate designs into wood surfaces, creating beautiful and tactile works of art. The AlgoLaser MK2, powered by AlgoOS, excels in this area thanks to its precise control and powerful laser module.

Preparing for Wood Relief Engraving

1. Selecting the Right Wood: Not all woods are created equal when it comes to laser engraving. Softwoods like pine are easier to engrave but may produce more residue, while hardwoods like oak provide cleaner results. Choose a wood that suits your project's requirements.

2. Design Preparation: Use design software compatible with AlgoOS to create or import your design. The Algo Graphics Engine within AlgoOS ensures that your design is processed quickly and accurately.

3. Setting Up the Laser Engraver: Secure the wood on the worktable of the AlgoLaser MK2. Ensure that the surface is flat and clean to avoid any distortions in the engraving.

Engraving Process

1. Adjusting Laser Settings: Use the 3.5-inch IPS capacitive touch screen to set the laser parameters. Adjust the power, speed, and resolution according to the type of wood and the intricacy of the design.

2. Focusing the Laser: Use the focusing post to set the correct height of the laser module. Accurate focusing is crucial for achieving detailed and precise engravings.

3. Engraving: Once everything is set, start the engraving process. The AlgoOS system allows you to monitor the progress in real-time and make adjustments if necessary.

Post-Engraving Finishing

1. Cleaning: Remove any residue left on the wood using a soft brush or cloth. For deeper cleanings, such as sap or resin, a gentle solvent may be used.

2. Finishing Touches: Apply a finish such as varnish or oil to enhance the wood's appearance and protect the engraved design.

Benefits of Using AlgoOS for Wood Relief Engraving

1. Precision: The Algo Graphics Engine processes images and designs with high accuracy, ensuring that every detail of your design is captured perfectly.

2. Ease of Use: The intuitive user interface of the AlgoOS makes it easy for anyone, regardless of experience level, to operate the laser engraver effectively.

3. Efficiency: With features like original image direct engraving and original SVG cutting, AlgoOS significantly reduces the time required to prepare and execute engraving tasks.

Mastering AlgoOS: The Heart of AlgoLaser MK2

The AlgoOS system is the backbone of the AlgoLaser MK2, providing a seamless and powerful platform for all your engraving and cutting needs. It simplifies complex tasks, enhances precision, and ensures smooth operation.

One-Touch to Engrave/Carve and Cut All on One Screen

AlgoOS consolidates the entire engraving and cutting process into a single, user-friendly interface. Here's how it works:

1. Selecting the File: Use the touch screen to browse and select the design file you want to engrave or cut. AlgoOS supports various file formats, making it versatile for different design sources.

2. Setting Parameters: Adjust the laser settings such as power, speed, and resolution directly on the touch screen. The system provides recommendations based on the material and design complexity.

3. Starting the Process: With just one touch, you can start the engraving or cutting process. The real-time monitoring feature allows you to track progress and make adjustments if needed.

Becoming an Engraving Expert in Three Steps

AlgoOS is designed to make laser engraving accessible to everyone. Here's how you can become an engraving expert in just three steps:

1. Power On: Turn on the AlgoLaser MK2 and let AlgoOS initialize. The system is ready to use within seconds.

2. Select File and Set Parameters: Choose your design file and adjust the necessary parameters. AlgoOS's intuitive interface guides you through the process.

3. Start Engraving: Begin the engraving or cutting process with a single touch. AlgoOS ensures smooth and precise execution.

The 3.5-Inch IPS Capacitive Touch Screen

The touch screen of the AlgoLaser MK2 is a standout feature, offering several advantages:

1. Simple as Using a Mobile Phone: With the AlgoOS, operating the MK2 laser engraver is as simple as using a mobile phone. The touch-based controls allow for precise adjustments and easy operation.

2. Clear Display: High-resolution display ensures that all details are visible, allowing for precise adjustments and real-time monitoring.

3. Responsive Touch: The capacitive touch screen responds quickly to inputs, providing a seamless user experience.

Independent Operation without LightBurn & LaserGRBL

One of the significant advantages of AlgoOS is its ability to operate independently without the need for additional software like LightBurn or LaserGRBL. This feature offers several benefits:

1. Simplified Workflow: Everything you need to design, adjust, and execute your projects is built into AlgoOS, streamlining the workflow.

2. Cost-Effective: Eliminates the need for purchasing additional software, reducing overall costs.

3. User-Friendly: AlgoOS's interface is designed to be intuitive and easy to use, even for those unfamiliar with traditional laser engraving software.

Original Image Direct Engraving & Original SVG Cutting: A Leap Forward

The AlgoLaser MK2's AlgoOS system, equipped with the Algo Graphics Engine, introduces groundbreaking features like original image direct engraving and original SVG cutting. These capabilities drastically reduce processing times and enhance the overall user experience.

The Power of Original Image Direct Engraving

Traditional laser engraving often involves lengthy image processing steps, including uploading, converting, and adjusting the design. AlgoOS simplifies this with its direct engraving capabilities:

1. Algo Graphics Engine: This powerful engine processes images quickly and accurately, reducing the time required to prepare designs for engraving.

2. Fast Processing: A 5M JPG image can be processed within 30 seconds, thanks to the Algo Graphics Engine. This rapid processing allows you to start your projects sooner.

3. Seamless Workflow: The entire process, from image processing to engraving, is completed within a minute. This seamless workflow eliminates waiting times and enhances productivity.

Original SVG Cutting: Precision and Efficiency

Original SVG cutting is another standout feature of AlgoOS, allowing for precise and efficient cutting of vector graphics. Here's how it enhances the cutting process:

1. Direct Cutting: Like direct engraving, original SVG cutting processes vector graphics without the need for lengthy conversions or adjustments.

2. Accuracy: The Algo Graphics Engine ensures that every detail of your SVG design is captured accurately during the cutting process.

3. Speed: The rapid processing capabilities of AlgoOS mean that even complex SVG designs can be cut quickly and efficiently.

Eliminating Long Upload Times

One of the significant advantages of AlgoOS is the elimination of long image upload times. Here's how it works:

1. Direct Processing: Instead of uploading images to an external software or cloud service, AlgoOS processes images directly on the device. This feature saves time and avoids potential upload issues.

2. Immediate Feedback: With direct processing, you receive immediate feedback on your design, allowing for quick adjustments and modifications if needed.

3. Increased Efficiency: By removing the upload step, the overall time required to complete a project is significantly reduced, enhancing efficiency and allowing you to complete more projects in less time.

Enhancing Creativity with Instant Processing

The ability to process images instantly opens up new possibilities for creativity:

1. Experimentation: With faster processing times, you can experiment with different designs and settings without worrying about lengthy delays. This flexibility encourages creativity and innovation.

2. On-the-Fly Adjustments: If you need to make changes to your design, you can do so quickly and see the results almost immediately. This feature is particularly useful for fine-tuning details and achieving the desired outcome.

3. Quick Prototyping: For businesses and designers, the ability to create quick prototypes is invaluable. The rapid processing capabilities of AlgoOS make it easy to test new ideas and bring them to life.

Advanced Hardware for Superior Performance

The powerful dual-core CPU and 32G memory of the AlgoLaser MK2 play a crucial role in supporting the original image direct engraving and original SVG cutting features:

1. High-Speed Processing: The advanced hardware ensures that even large and complex images are processed quickly and efficiently.

2. Smooth Operation: The combination of powerful processing and ample memory provides smooth operation without any lag or interruptions.

3. Reliable Performance: Whether you are working on a single project or batch engraving, the AlgoLaser MK2 delivers consistent and reliable performance, thanks to its robust hardware.

Unleashing the Power of AlgoLaser MK2's Hardware

The AlgoLaser MK2 laser engraver is not just about its advanced software capabilities; its hardware is equally impressive. Equipped with a dual-core CPU and 32G memory, the AlgoLaser MK2 sets a new standard in laser engraving and cutting performance.

The Dual-Core CPU: Speed and Efficiency

The dual-core CPU in the AlgoLaser MK2 provides several benefits:

1. High-Speed Processing: The dual-core architecture allows for high-speed processing of complex designs, ensuring that your projects are completed quickly and efficiently.

2. Multitasking: The dual-core CPU enables the laser engraver to handle multiple tasks simultaneously, such as processing images while executing engraving or cutting commands.

3. Enhanced Performance: The powerful CPU ensures smooth and uninterrupted operation, even when dealing with large and intricate designs.

The 32G Memory: Ample Storage and Smooth Operation

The 32G memory in the AlgoLaser MK2 is another standout feature:

1. Ample Storage: With 32G of memory, you can store multiple design files directly on the device, eliminating the need for constant file transfers.

2. Smooth Operation: The ample memory ensures that the laser engraver operates smoothly, even when processing large files or complex graphics.

3. Backup Capabilities: The large memory capacity allows for the backup of important design files and data, ensuring that your projects are safe and secure.

Superior Performance for Complex Projects

The combination of a dual-core CPU and 32G memory provides the AlgoLaser MK2 with the power and capability to handle complex projects with ease:

1. Large Engraving Images: The powerful hardware can process and engrave large images without any lag or interruptions, ensuring high-quality results.

2. Complex Graphics: Intricate designs and complex graphics are processed smoothly, thanks to the advanced hardware capabilities of the AlgoLaser MK2.

3. Consistent Quality: The robust hardware ensures consistent quality and performance, regardless of the complexity or size of the project.

Enhancing User Experience with Advanced Hardware

The advanced hardware of the AlgoLaser MK2 enhances the overall user experience in several ways:

1. Faster Processing Times: The dual-core CPU and 32G memory significantly reduce processing times, allowing you to complete projects faster and more efficiently.

2. Smooth Operation: The powerful hardware ensures smooth and uninterrupted operation, providing a seamless user experience.

3. Reliable Performance: The advanced hardware delivers consistent and reliable performance, ensuring that your projects are completed to the highest standard.

Say Goodbye to Engraving Interruptions with Power-Off Resume

One of the most frustrating aspects of laser engraving is dealing with interruptions. Whether due to power outages or other unexpected issues, interruptions can disrupt your workflow and waste valuable time and materials. The AlgoLaser MK2, with its AlgoOS system, addresses this issue with its innovative power-off resume function.

The Power-Off Resume Function

The power-off resume function in AlgoOS ensures that your engraving tasks are completed, even in the event of an interruption. Here's how it works:

1. High-Precision Control System: AlgoOS uses a high-precision control system to track the progress of your engraving tasks accurately.

2. Data Storage Capabilities: The system stores detailed information about the current state of the engraving task, including the exact position of the laser head and the progress made so far.

3. Automatic Resumption: In the event of an interruption, such as a power outage, AlgoOS automatically resumes the engraving task from the point where it was interrupted once power is restored.

Benefits of the Power-Off Resume Function

1. Minimizes Material Waste: By resuming tasks from the point of interruption, the power-off resume function minimizes material waste, saving you time and money.

2. Saves Time: Instead of restarting the engraving task from the beginning, AlgoOS resumes the task from where it left off, saving valuable time and ensuring efficient operation.

3. Ensures Consistency: The high-precision control system ensures that the resumed engraving task is consistent with the original, maintaining the quality and accuracy of your projects.

How to Use the Power-Off Resume Function

Using the power-off resume function is straightforward:

1. Enable the Function: Ensure that the power-off resume function is enabled in the AlgoOS settings.

2. Start Engraving: Begin your engraving task as usual.

3. Automatic Resumption: In the event of an interruption, AlgoOS will automatically resume the task from the point of interruption once power is restored.

Practical Applications of the Power-Off Resume Function

The power-off resume function is particularly useful in various practical applications:

1. Large Projects: For large engraving projects that take a significant amount of time, the power-off resume function ensures that interruptions do not result in wasted time or materials.

2. Batch Production: In batch production scenarios, the power-off resume function ensures that interruptions do not disrupt the entire batch, maintaining consistency and efficiency.

3. Unreliable Power Supply: In areas with an unreliable power supply, the power-off resume function provides peace of mind, ensuring that your projects are completed regardless of power interruptions.

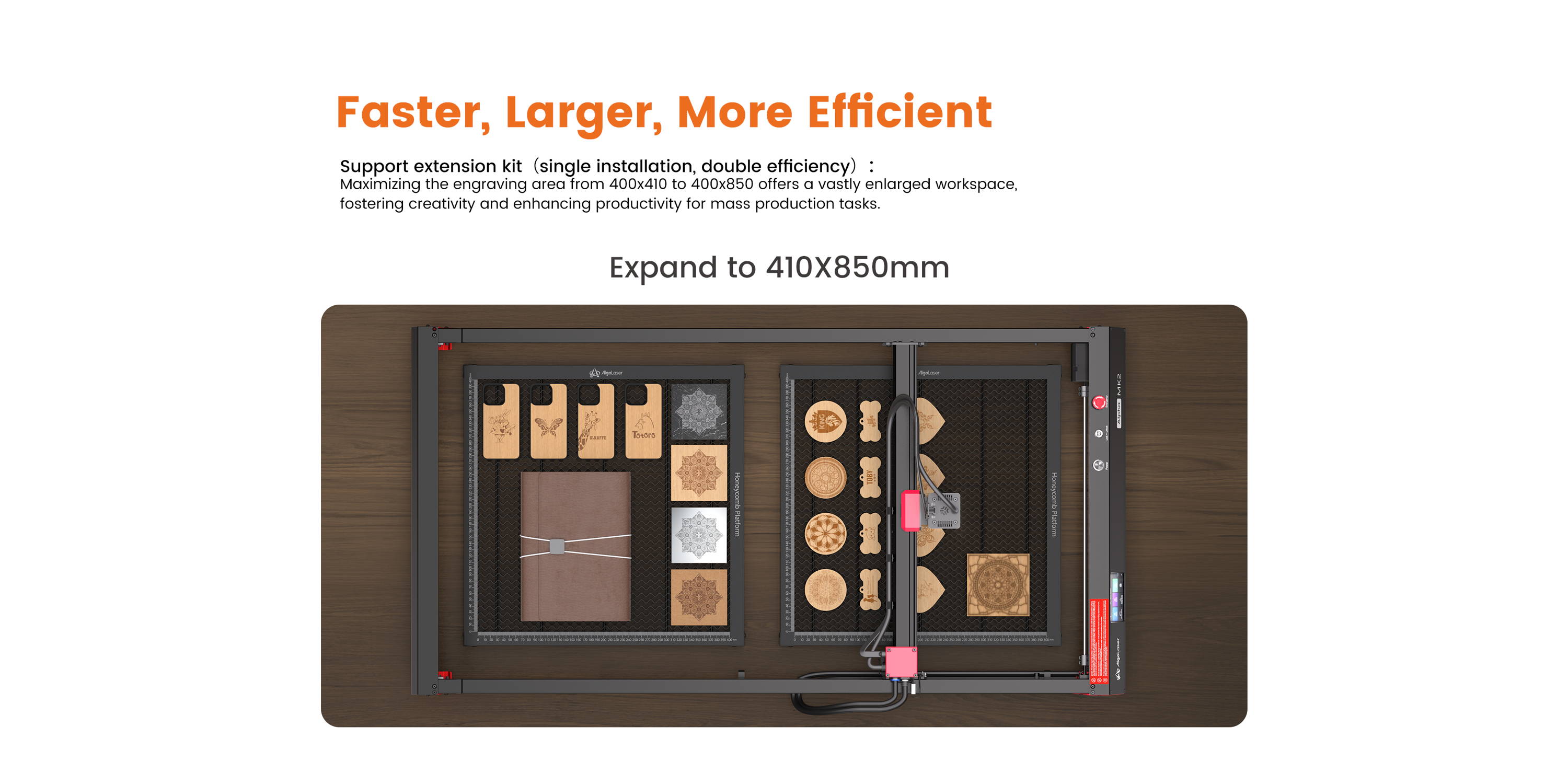

Easy Batch Engraving with AlgoOS: Streamlining Production

Batch engraving is a common requirement for many users, whether for personalized gifts, promotional items, or production runs. The AlgoLaser MK2, with its AlgoOS system, makes batch engraving easy and efficient with its one-click batch engraving feature.

The One-Click Batch Engraving Feature

AlgoOS's one-click batch engraving feature simplifies the process of creating multiple identical items. Here's how it works:

1. Initial Setup: Complete the first engraving task as usual, setting the parameters and ensuring the design is perfect.

2. One-Click Again: Once the first task is complete, simply click the "Again" button to repeat the same engraving operation automatically.

3. Automated Operation: Algo

Benefits of One-Click Batch Engraving

1. Time Efficiency: By automating the batch engraving process, AlgoOS significantly reduces the time required to complete multiple items.

2. Consistency: The automated process ensures that each item in the batch is identical, maintaining high-quality standards.

3. Ease of Use: The one-click operation makes batch engraving accessible to all users, regardless of experience level.

Practical Applications of Batch Engraving

Batch engraving is useful in various scenarios:

1. Personalized Gifts: Create multiple personalized gifts quickly and efficiently, perfect for events, weddings, and corporate giveaways.

2. Promotional Items: Produce large quantities of promotional items such as keychains, coasters, or pens with consistent quality.

3. Production Runs: For small-scale production runs, the batch engraving feature streamlines the process, reducing labor and increasing productivity.

Steps for Successful Batch Engraving

1. Prepare the Design: Ensure that your design is finalized and ready for engraving. Use design software compatible with AlgoOS to create or import your design.

2. Set Parameters: Adjust the laser settings such as power, speed, and resolution for the first item in the batch.

3. Engrave the First Item: Complete the first engraving task, ensuring that the design and settings are correct.

4. Initiate Batch Engraving: Click the "Again" button to start the batch engraving process. AlgoOS will handle the rest, repeating the engraving operation for each item in the batch.

Enhancing Productivity with Batch Engraving

The batch engraving feature of AlgoOS enhances productivity in several ways:

1. Reduced Manual Labor: Automating the engraving process reduces the need for manual intervention, freeing up time for other tasks.

2. Increased Output: By streamlining the engraving process, you can produce more items in less time, increasing overall output.

3. Consistent Quality: The automated process ensures that each item in the batch meets the same high-quality standards, maintaining consistency across all items.

One-Tap Precision and Preview: Achieving Accurate Engravings

Precision is crucial in laser engraving, and the AlgoLaser MK2, with its AlgoOS system, ensures that you achieve accurate and precise engravings every time. The one-tap precision and preview features of AlgoOS make it easy to set up and execute your engraving tasks with confidence.

One-Tap Precision: Setting the Starting Point

The one-tap precision feature of AlgoOS simplifies the process of setting the starting point for your engraving:

1. Tap and Drag: Use the touch screen to tap and drag freely, setting the starting point exactly where you want it. This feature eliminates the need for tedious origin calibration.

2. Instant Feedback: The system provides instant feedback, allowing you to see the exact position of the starting point and make adjustments as needed.

3. Time-Saving: By streamlining the process of setting the starting point, one-tap precision saves valuable time and ensures accuracy.

Preview Feature: Visualizing the Engraving Range

The preview feature of AlgoOS allows you to visualize the engraving range before starting the task:

1. Preview the Range: Before starting the engraving, use the touch screen to preview the engraving range. The system displays the area that will be engraved, providing a clear visualization.

2. Adjust as Needed: If the preview shows that the engraving range is not correct, make adjustments to the design or settings as needed.

3. Avoid Mistakes: The preview feature helps you avoid mistakes such as engraving outside the desired area or missing parts of the design.

Benefits of One-Tap Precision and Preview

1. Accuracy: Both features ensure that your engravings are accurate and precise, capturing every detail of your design.

2. Efficiency: By simplifying the setup process and providing instant feedback, these features enhance efficiency and reduce setup time.

3. User-Friendly: The intuitive touch screen interface makes it easy for all users, regardless of experience level, to achieve precise engravings.

Practical Applications

The one-tap precision and preview features are particularly useful in various practical applications:

1. Detailed Designs: For intricate and detailed designs, these features ensure that every element is captured accurately.

2. Custom Projects: When working on custom projects, the ability to set the starting point precisely and preview the engraving range ensures that the final result meets the client’s expectations.

3. Batch Production: In batch production scenarios, these features ensure consistency and accuracy across all items, maintaining high-quality standards.

Steps for Using One-Tap Precision and Preview

1. Prepare the Design: Finalize your design and import it into AlgoOS.

2. Set the Starting Point: Use the one-tap precision feature to set the starting point by tapping and dragging on the touch screen.

3. Preview the Engraving Range: Use the preview feature to visualize the engraving range and make any necessary adjustments.

4. Start Engraving: Once everything is set, start the engraving task with confidence, knowing that your design will be captured accurately and precisely.

Comprehensive Accessories for AlgoOS Series Products

The AlgoLaser MK2, powered by the AlgoOS system, is not only a powerful laser engraver but also a versatile tool that can be customized and enhanced with a range of accessories. In this article, we will explore the comprehensive accessory options available for the AlgoOS series products and how they can further enhance your engraving and cutting experience.

Enhancing Functionality with Essential Accessories

To get the most out of your AlgoLaser MK2, consider these essential accessories that enhance its functionality and expand its capabilities:

1. Air Assist: The air assist accessory helps to keep the laser lens clean and improve cutting performance by blowing away smoke and debris. This results in cleaner cuts and prolongs the life of the laser.

2. Rotary Attachment: For engraving cylindrical objects like glasses and bottles, the rotary attachment is a must-have. It allows the laser to engrave around the circumference of the object, expanding your creative possibilities.

3. Honeycomb Work Table: The honeycomb work table provides a stable and supportive surface for engraving and cutting. It helps to reduce back reflections and ensures that your materials stay in place during the process.

Expanding Creative Possibilities with Specialized Accessories

Specialized accessories can take your engraving and cutting projects to the next level. Here are some options to consider:

1. Material Packs: AlgoLaser offers material packs specifically designed for laser engraving and cutting. These packs include a variety of materials such as wood, acrylic, leather, and more, allowing you to experiment and create diverse projects.

2. Protective Enclosure: A protective enclosure is an essential accessory for safety and cleanliness. It helps to contain smoke and fumes generated during the engraving process, ensuring a safe and clean working environment.

3. Camera Module: The camera module accessory enhances precision by providing a live feed of the engraving area. This feature is particularly useful for aligning designs and ensuring accurate placement.

Optimizing Performance with Maintenance Accessories

Regular maintenance is crucial for keeping your AlgoLaser MK2 in top condition. Consider these maintenance accessories to optimize performance:

1. Lens Cleaning Kit: A lens cleaning kit is essential for maintaining the clarity and effectiveness of your laser lens. Regular cleaning ensures that your laser operates at peak performance.

2. Replacement Parts: Keep a stock of replacement parts such as belts, wheels, and bearings to minimize downtime in case of wear and tear. Having these parts on hand ensures that you can quickly address any maintenance issues.

3. Lubrication Kit: Proper lubrication of moving parts is crucial for smooth operation. A lubrication kit helps to maintain the longevity and performance of your laser engraver.

Conclusion

The AlgoLaser MK2, powered by the innovative AlgoOS system, sets a new standard in the world of laser engraving and cutting. From wood relief engraving to advanced hardware capabilities, from one-touch operations to powerful accessories, the AlgoLaser MK2 offers a comprehensive solution for all your engraving needs.

- Choosing a selection results in a full page refresh.