Laser Use Safety And Protection

Today's main update is about laser safety and protection. Due to the rapid expansion of laser applications, more and more traditional fields are beginning to utilize lasers, such as laser cutting, welding, marking, and cladding. However, there is a lack of necessary training for engineers and technicians, resulting in a considerable number of frontline workers being exposed to laser radiation for extended periods. They are unaware of the harm lasers can cause, and business managers are also oblivious to the dangers of lasers. Over time, this can lead to irreversible occupational diseases for on-site personnel. Laser technology itself is not frightening; all that is needed is adequate protection to ensure safety. Therefore, this article aims to raise awareness of the hazards and protection measures related to lasers among laser equipment integrators, manufacturers selling laser products, frontline production managers, engineers, and other stakeholders. It is essential for companies to take on the social responsibility of producing safe products, and for frontline engineers to learn how to protect themselves.

Laser safety training is crucial for the safety and efficiency of laser welding operations. During the laser welding process, the potential risks to the health of operators arise from the possibility of high-intensity light, heat, and harmful gases being generated. Through laser safety training, engineers and operators can learn how to correctly use personal protective equipment, such as protective goggles and face shields, and how to avoid direct or indirect contact with the laser beam, ensuring effective protection for their eyes and skin.

Hazards of Laser

Laser exposure can cause serious skin damage, hence the need for skin protection, but eye injury is the primary danger. Beam damage can be divided into three forms:

Thermal - This is the result of exposed areas generating and absorbing heat, leading to burns on the skin and eyes.

Acoustic - This produces mechanical shock waves, similar to the ripple effect of throwing a pebble into a pond. Acoustic effects can result in localized vaporization and tissue damage.

Photochemical - Certain wavelengths can induce chemical reactions in tissues, in some cases leading to burns on the lens, cornea, or retina, and increasing the risk of skin cancer.

The effects of lasers on the skin vary, ranging from mild redness and pain to third-degree burns, depending on the laser category, pulse duration and repetition rate, and wavelength.

Eye injury is a primary concern. The impact on the eyes depends on various factors, including pupil size, pigment deposition, laser pulse duration and repetition rate, and wavelength. Different wavelengths penetrate the eyes to different depths, causing damage to that layer and to the cornea, lens, or retina:

The high temperature generated by lasers can cause protein coagulation or vaporization in an instant, thereby harming biological tissues. The eyes are the most sensitive organs to lasers in the human body. Due to the focusing effect of the eyeball on light, the energy density on the retina can increase by 105 times. Therefore, even low-dose irradiation can cause severe damage to the retina, leading to vision loss or even blindness.

Different wavelengths of lasers cause different damage to the eyes. Because the transparency of the eyes to different wavelengths of lasers varies, the damage caused by lasers of different wavelengths to the eyes differs. Therefore, without wearing protective goggles, directly looking at the laser welding process can cause irreversible damage to the eyes.

Due to the focusing effect of the human eye, weak external light entering the eye will be focused, resulting in an increase in energy density, thus exerting a stronger damaging effect on the eye.

The infrared light emitted by lasers poses significant harm to the human eye, causing burns to the retina, leading to decreased vision or even blindness. When the light beam enters the pupil, it penetrates the lens and focuses onto the retina, precisely onto the macula, the most sensitive area of the retina. After this area is damaged, there will always be a black spot in the central area of the visual field, which cannot be restored. Due to the invisibility of infrared light, even a small amount of laser entering the eye cannot trigger a timely blink reflex, allowing the laser to continuously enter the pupil, causing greater damage than visible light. Therefore, it is essential to wear protective goggles when conducting laser processing operations, and ideally, full-body protection should be provided when conditions permit.

When the lighting in a room is dim, the pupils dilate to admit more light, allowing for clearer observation. If there is laser radiation in such dimly lit conditions, the amount of laser entering the eye increases, resulting in more severe eye damage. Therefore, workstations and protective rooms must be adequately illuminated, and factory lighting should be sufficient to prevent greater eye damage.

Harm of Laser to the Skin:

Laser irradiation on the skin can lead to burns, erythema, blisters, pigment deposition, and ultimately, complete destruction of subcutaneous tissue. Different wavelengths can reach different depths of skin tissue (as shown in the diagram below). Generally, longer wavelengths have stronger penetration capabilities. At 400nm, skin tissue penetration does not exceed 1mm, reaching the dermis layer; at 514nm, penetration ranges approximately from 0.5mm to 2mm; and at 630nm, penetration ranges approximately from 1mm to 6mm. Infrared light at 1070nm can penetrate the epidermis, dermis, and even reach subcutaneous tissue.

Which lasers pose a threat?

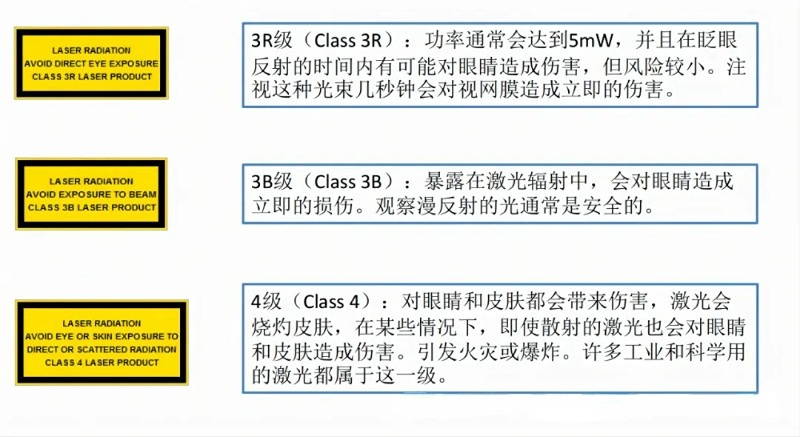

According to various standards, laser hazards to the human eye and skin are classified as follows:

Industrial high-power lasers outputting wavelengths of 400-1080 nm invisible laser radiation (including semiconductor lasers (blue, red light) and fiber lasers (red, green light), as well as carbon dioxide lasers at 10.6um). According to the IEC EN 60825-1 standard, the laser classification for the fiber output of all laser systems is Class 4. Users are responsible for ensuring that the fiber output end or optical processing head is in a protective enclosure to ensure that the laser radiation level is Class 1.

Closed laser cabinets, conductive fibers, and operating fibers (except for fiber output ends) have a safety level of Class 1. When connected to an optical processing head, the level at the processing head location is Class 4.

Laser systems integrate Class 2M guide lasers. Guide lasers are red light laser diodes emitting wavelengths of 635nm or 658nm, with an output optical power less than 1mW. Direct viewing of this guide laser beam with the naked eye or optical instruments is not allowed.

How to properly protect against lasers

This is primarily explained from three aspects:

Providers of laser products:

Laser Manufacturers (laser equipment, handheld welders, and small engraving machine products): Alongside providing laser products, manufacturers should also offer necessary personal laser protection equipment (such as goggles), safety labels, usage instructions, safety training manuals, etc. This practice, as demonstrated by IPG's services, not only embodies corporate social responsibility but also demonstrates responsibility for the safety of users. It's essential to inform users to avoid injury.

Integrators: Required services include:

Protective shields and laser safety rooms: Every laser product must be equipped with protective shields to prevent personnel from encountering laser radiation exceeding Class 1.

Barriers and safety interlocks: Accessible emissions should not be lower than the given category's accessible emission limit (AEL) value. Laser products need safety interlocks, and the design of safety interlocks must prevent the barriers from being moved aside.

Key controllers: Any laser system belonging to Class 3B and 4 must install key controllers. Key controllers refer to the main switch operated with a key that must be removable and kept by a designated person. Keys can also be magnetic cards or password systems.

For Class 4 laser products, remote operation is advisable to avoid direct entry of personnel into the laser radiation area.

It's imperative to provide customers with necessary laser safety training to prevent irreversible injuries due to ignorance.

Provide laser safety signage (radiation warning signs, warning lights, etc.)

Terminal Customer Use:

a) The management of laser usage must be carried out by professional personnel who have undergone training. Unauthorized personnel are not allowed to operate lasers without training.

b) Install an interlocking key switch on the trigger system of laser equipment to ensure that the laser can only be triggered after the interlocking switch is opened with a key. Once the key is removed, the laser cannot be activated.

c) Rooms where lasers are placed should have bright lighting. In bright light environments, the pupils of the eyes shrink, reducing the amount of light transmitted to the retina when the laser beam enters the eye.

d) For the height of the laser placement, the path of the laser beam should avoid the horizontal position of the eyes when a person is standing or sitting normally, and the visual axis of the eyes should not be parallel to the beam outlet.

Medical Supervision:

a) Staff using Class 3B and 4 laser products should undergo medical examinations by qualified medical personnel.

b) Staff using Class 3B and 4 laser products should undergo medical examinations before, during, and after work, and original records should be kept.

c) For staff exposed to a significant amount of laser radiation, it is advisable to consume foods such as rapeseed, cabbage, and radish, which have a radioprotective effect.

Personnel Training: Educating and training personnel who operate lasers.

a) Familiarity with the entire laser system operation process.

b) Proper personal protection.

c) Correct implementation of hazard control procedures.

d) Proper use of warning labels.

e) Establishing accident reporting procedures.

f) Understanding the biological effects of lasers on the eyes and skin.

Strict Control of Lasers:

a) Laser beams must not be directed at the human body, especially the eyes, in rooms where lasers are stored and used, as the damage to the eyes caused by lasers is extremely difficult to recover and is permanent.

b) Before starting the laser, personnel in the area must be warned of potential hazards and must wear safety goggles.

c) Obvious warning signs should be posted in and around areas with powerful lasers and on the doors of laser laboratories.

Controlled Laser Zone:

a) Laser equipment should only be used in designated areas.

b) Entrance to controlled areas should be equipped with guards and secure locks to prevent unauthorized access, and even if a door is accidentally opened, the laser should immediately stop working.

c) Rooms should be non-translucent to prevent harmful laser beams from leaking out. Emergency switches should be installed to stop the laser immediately in case of danger.

d) Items with mirror-like reflective properties should not be placed around the laser system to prevent injuries to on-site personnel from multiple reflections.

e) Unauthorized personnel unrelated to work should be strictly prohibited from entering the laser-controlled area.

Correct Use of Various Warning and Safety Signs:

a) Warning signs should be prominently displayed on the outer shell and control panel of laser equipment, using standard signs appropriate to the specific level of hazard posed by the laser, with visibility being optimal.

b) Work areas for Class 3B and 4 laser products or their enclosed protective barriers should be equipped with corresponding warning signs at entrances.

The Use of Laser Product Safety Labels:

a) All laser products must be affixed with laser safety labels.

b) Each device must have laser warning labels, laser radiation classification explanations, radiation windows, and other safety labels simultaneously.

c) Laser safety labels must be placed in locations visible to the human eye and not subject to laser damage.

Conclusion

Laser Operator Authorization: Clearly define employees' permissions for using lasers, with different levels of operational permissions.

Establishment of Rules and Regulations: Strictly control areas involving laser radiation, and establish guidelines for safe laser operation.

Supervision and Inspection Mechanism: Regularly maintain and inspect the feasibility of safety systems and facilities, ensuring correct implementation and use.

Manual Safety Training: Implement safety training mechanisms for new employees and regular evaluation mechanisms for existing employees to enhance their safety awareness.

Personal Protective Guidelines for Process Engineers, Equipment Technicians, and Operators:

Given that some managers and unscrupulous businesses may not meet the above requirements, individuals need to take personal protective measures when using lasers.

Personal Protective Equipment:

When engineering and management control measures cannot sufficiently reduce risks, personal protective equipment is used as the last resort. Laser personal protective equipment may include:

Laser Safety Glasses: Attenuate laser radiation to protect the eyes. Laser safety glasses must meet specific requirements: they must be approved and labeled according to national standards; they must be suitable for the type, wavelength, operation mode (continuous wave and pulsed wave), and power settings of the laser; laser safety glasses should have clear markings for proper selection for a specific laser; the frames and side parts should provide certain protective capabilities.

Eye Protection:

a) After implementing the above measures, if the eyes are still at risk of being exposed to laser radiation exceeding safety standards, appropriate protective eyewear with suitable optical density must be selected based on the wavelength of such lasers to enhance eye protection.

b) It is not sufficient to rely solely on protective eyewear; even when wearing protective eyewear, direct exposure to the laser beam should be avoided.

Selection of Laser Protective Clothing: Gloves or specialized garments to minimize skin exposure.

1. Provide suitable protective clothing for personnel exposed to radiation exceeding the skin's maximum permissible exposure (MPE) value as much as possible.

2. Protective clothing should be made of suitable flame-resistant and heat-resistant materials.

3. Skin should be minimally exposed while wearing protective clothing.

Skin Protection:

a) Wear long-sleeved work clothing made of flame-resistant materials.

b) In laser-controlled areas, install curtains and light-blocking panels made of flame-resistant materials coated with black or blue silicone to absorb ultraviolet radiation and block infrared radiation.