Traditional Stone Carving vs. Diode, CO₂, and Fiber Lasers

Stone engraving is an ancient art form that has undergone immense transformation, from primitive chisels and hammers used by ancient civilizations to modern-day laser technology. With the rise of diode lasers, CO₂ lasers, and fiber lasers, stone engraving has become faster, more accessible, and more precise. While traditional stone carving still holds significant cultural and artistic value, laser engraving has become a preferred method for many creators due to its efficiency, precision, and versatility.

In this comprehensive guide, we’ll explore the different engraving techniques, compare diode laser engraving with traditional stone carving and other types of lasers, and highlight real-world applications and community insights from Reddit on how diode lasers are revolutionizing stone engraving.

Traditional Stone Carving: Tools and Techniques

Before the advent of laser engraving, stone carving was a highly labor-intensive process. Ancient artisans relied on simple manual tools like hammers, chisels, abrasives, and grinding stones to shape stone into sculptures, architectural reliefs, and monuments. Traditional stone carving required immense patience, skill, and attention to detail.

Steps Involved in Traditional Stone Carving

1. Roughing Out: The first step involves removing large chunks of stone using heavy tools like a point chisel and mallet to get the basic shape.

2. Detailing: After shaping the stone, finer chisels and rifflers are used to refine the details, carving more intricate patterns or text.

3. Polishing: The final step involves smoothing the stone surface using abrasives or polishing wheels to achieve a shiny finish.

Benefits and Limitations of Traditional Stone Carving

· Durable Results: Traditional stone carvings produce tactile, deeply textured, and permanent results, often with high artistic value.

· Time-Consuming: Stone carving can take days, weeks, or even months, depending on the scale and intricacy of the project.

· Physical Effort: It requires significant manual dexterity and physical labor, and any mistakes could irreparably damage the stone.

· Inconsistent Precision: The quality of carving depends heavily on the artisan’s skill, meaning each piece is unique but may lack consistent precision.

Despite its challenges, traditional stone carving remains highly revered for its artistic and historical significance. However, for most modern stone engraving needs, laser technology has emerged as the superior method due to its precision, speed, and ease of use.

Diode Laser Engraving on Stone: A Game-Changer for Hobbyists and Small Businesses

Diode lasers have gained popularity in recent years for stone engraving , especially among hobbyists, small business owners, and makers. Their affordability, compact size, and ease of use have made them accessible to a broader audience.

Why Diode Lasers Are Highly Recommended for Stone Engraving

· Affordable & Compact: Diode laser engravers are typically much more affordable than CO₂ lasers or fiber lasers. Their small, portable design makes them perfect for home setups or small workshops.

· High Precision: Diode lasers offer high-resolution settings and can achieve a precision of up to 0.05 mm, making them ideal for intricate designs, text, and photos on stone.

· Ease of Use: Many diode laser engravers come with user-friendly software, making them accessible to beginners. They are also low-maintenance and require minimal upkeep.

· Versatility: Diode lasers can engrave a wide range of materials, including wood, leather, acrylic, and stone. They are particularly effective for surface engraving, which is ideal for personalizing items like plaques, coasters, and memorial stones.

Challenges of Diode Lasers for Stone Engraving

· Limited Cutting Depth: Diode lasers generally lack the power needed to cut deeply into hard stones like granite or marble. However, they excel at shallow engravings on softer stones like slate, soapstone, and limestone.

· Slow Engraving Speed on Harder Stones: While diode lasers can be fast on softer materials, engraving on harder stones often requires multiple passes and lower power, resulting in slower processing times.

Comparison Chart: Traditional Stone Carving vs. Diode, CO₂, and Fiber Lasers

To provide a clearer overview of how diode laser engraving compares to traditional and other laser engraving methods, here's a detailed comparison:

| Method | Tools / Equipment | Precision & Detail | Speed & Efficiency | Cost | Durability of Result | Best For |

|---|

| Traditional Carving | Chisels, hammers, abrasives | Moderate (artisan-dependent) | Very slow, labor-intensive | Low tool cost, high labor | Very durable, tactile | Sculpture, monuments, cultural works |

| Diode Laser | Compact diode laser engraver | High precision, fine detail | Moderate speed, great for small-scale | Low to moderate | Long-lasting, surface etching | Personalized gifts, memorials, decorative pieces |

| CO₂ Laser | CO₂ laser engraver (higher power) | High precision, deep engraving | Faster than diode, deep cuts | Moderate to high | Durable, deep engravings | Industrial projects, cutting, and detailed engraving |

| Fiber Laser | Industrial fiber laser system | Extremely high precision | Very fast, high throughput | High to very high | Very durable, permanent | Professional industrial marking, jewelry, micro-engraving |

Real-World Examples: Diode Laser Projects on Stone

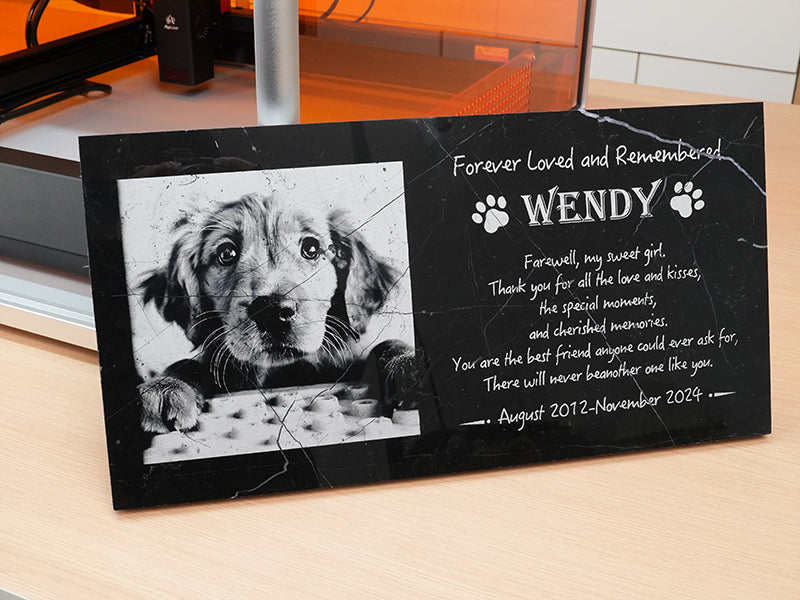

1. Personalized Memorial Stones

A Reddit user shared their experience using a 5W diode laser to engrave a memorial plaque on slate. They noted that multiple passes were necessary, but the results were crisp and detailed, especially after filling the engraving with black paint for enhanced contrast.

"I used the laser on a small slate memorial stone for a friend. It took several passes, but the result was crisp and detailed. I filled in the engraving with black paint, which helped the text stand out even more."

2. Custom Coasters and Gifts

Another Reddit user successfully used a 20W diode laser to create custom stone coasters for gifts. The high contrast and clear designs on granite were achieved after several passes at lower power.

"Creating personalized stone coasters with the diode laser was super fun. It took some trial and error, but the final product looked amazing, especially when filled with white acrylic paint."

3. Engraved Stone Tiles for Home Decor

A hobbyist shared their success in engraving intricate tile designs on ceramic stone tiles. After optimizing the power and speed settings, they achieved crisp, detailed results perfect for home décor.

"I engraved some decorative tiles for my kitchen with a diode laser. The results were crisp, and the tiles are now a focal point in my kitchen decor!"

4. Wedding or Anniversary Gifts

A user described using their diode laser to create personalized wedding or anniversary gifts, engraving romantic quotes on slate. They found the process quick and easy, and the slate held the fine detail well.

"I love how easy it is to create custom wedding gifts with my diode laser. The engraving process was quick, and the slate really holds up well, even with all the detail."

Conclusion: Why Diode Lasers Are the Best Choice for Stone Engraving

While traditional stone carving is still a timeless, tactile art form, diode laser engraving is the ideal choice for most modern applications. The affordability, precision, and versatility of diode lasers make them perfect for hobbyists, small business owners , and makers creating personalized stone products.

With diode lasers, users can achieve professional-quality engravings on stone without the steep learning curve or hefty investment associated with other methods like CO₂ lasers or fiber lasers. Whether you're engraving memorial plaques, custom gifts, or home décor, diode laser engravers provide a reliable and cost-effective solution for your stone engraving needs.

- Choosing a selection results in a full page refresh.