Turning Wood into Gold: How to Make Money Woodworking with a Laser Engraver

Woodworking has been a beloved craft for generations, allowing individuals to create functional and artistic pieces from wood. But in today's world, the integration of technology has opened up new horizons for woodworkers to not only create stunning wooden items but also to add intricate designs and personalization. The magic wand in this transformation is the laser engraver, a tool that can take your woodworking to the next level and help you turn your passion into profit. In this comprehensive guide, we will explore how to make money woodworking with a laser engraver, covering various aspects from understanding woodworking and laser engraving to starting and selling your woodworking business. Let's embark on this creative journey!

What is Woodworking?

Before we dive into how to make money with woodworking and laser engraving, let's define what woodworking is:

Woodworking is the art and craft of creating objects from wood. It involves various processes, including cutting, carving, shaping, and joining wood to create functional and decorative items. Woodworking projects range from small, intricate carvings to large-scale furniture and cabinetry.

Ways to Make Money in Woodworking

Woodworking can be a fulfilling hobby, but it can also be a profitable business venture. Here are some of the ways you make money with woodworking:

1. Craft and Sell Wood Products:

Create and sell handmade wooden items such as cutting boards, furniture, and home decor.

Customization options make your products stand out.

2. Woodworking Classes and Workshops:

Teach woodworking classes to beginners or enthusiasts looking to learn the craft.

Offer workshops for hands-on experience.

3. Furniture Restoration:

Restore and refurbish old furniture to its former glory.

Sell the restored pieces for a profit.

4. Woodworking Plans and Guides:

Create and sell woodworking plans and guides.

Share your expertise with fellow woodworkers.

5. Woodworking YouTube Channel or Blog:

Share your woodworking journey through videos or articles.

Monetize your content through ads and sponsorships.

6. Custom Woodworking Services:

Offer custom woodworking services, such as creating bespoke pieces for clients.

Collaborate with interior designers for projects.

Now, let's explore how laser engraving can enhance your woodworking and open up new avenues for profit.

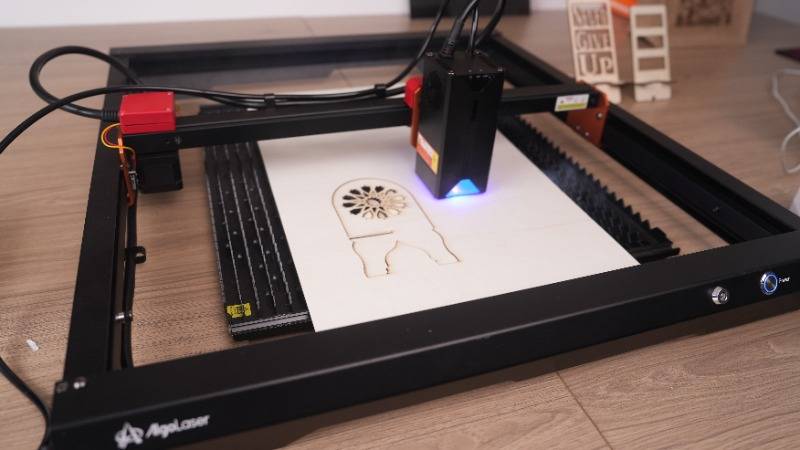

Laser Engraving Machines for Woodworking

Laser engraving machines are versatile tools that can make your woodworking projects more creative and profitable. There are primarily two types of lasers used for engraving:

1. CO2 Lasers:

CO2 lasers are the most common choice for engraving wood.

They work well for etching intricate designs and patterns into wood surfaces.

These lasers are effective on various wood types, including hardwoods and softwoods.

2. Fiber Lasers:

Fiber lasers are known for their precision and are excellent for marking and engraving on wood.

They create a high-contrast, detailed finish.

Fiber lasers work exceptionally well on hardwoods.

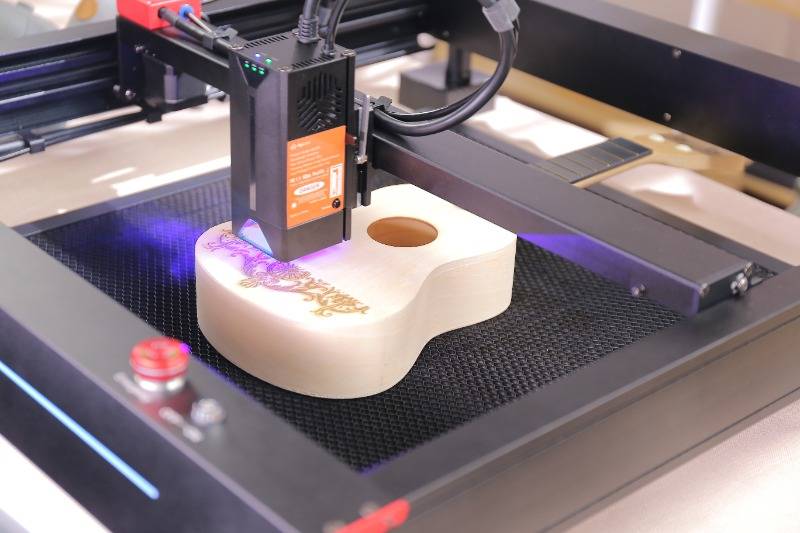

3. Diode Laser

Diode laser engravers have gained popularity in the woodworking industry due to their precision and ease of use. These machines are well-suited for various woodworking applications, including engraving, etching, and cutting. Here are some characteristics and considerations when using diode laser engraving machines for woodworking:

Diode laser engraving machines are known for their precision, making them ideal for intricate woodwork designs. They can produce fine details, intricate patterns, and small text with high accuracy.

Diode lasers can be used on various wood types, including hardwoods and softwoods. They are also compatible with wood-based materials such as plywood, MDF, and veneers, allowing for a wide range of woodworking applications.

These machines are user-friendly and often come with intuitive software that enables easy design import and customization. This makes diode laser engraving accessible to both beginners and experienced woodworkers.

Diode lasers work well with various wood types, allowing you to create customized and personalized wood products.

How to Use Laser Engraving Machines for Woodworking Engraving

Laser engraving can take your woodworking projects to a new level by adding intricate designs, personalization, and unique patterns to your creations. Here's how you can effectively use laser engraving machines for woodworking:

1. Design Selection:

Choose or create a design or pattern that complements your woodworking project.

Ensure the design is suitable for the wood type and size.

2. Surface Preparation:

Prepare the wood surface by sanding it to ensure a smooth and even finish.

Clean the surface to remove any dust or debris.

3. Machine Calibration:

Calibrate your laser engraving machine to the appropriate settings for the wood type and design.

Ensure the focal length and laser power are set correctly.

4. Testing:

Before engraving on your final piece, conduct a test run on a scrap or sample piece of wood.

This helps you fine-tune the settings and make any necessary adjustments.

5. Engraving:

Place your wood piece in the laser engraver and initiate the engraving process.

Monitor the engraving to ensure it progresses as expected.

6. Post-Processing:

Once the engraving is complete, inspect the wood piece for any residue or imperfections.

Clean the engraved area and sand it if needed for a smooth finish.

7. Finishing Touches:

Apply a finish, such as varnish or oil, to protect and enhance the wood's appearance.

Ensure the finish complements the engraved design.

With laser engraving, you can offer customized wood products, including engraved names, quotes, or images, adding significant value to your woodworking projects.

How to Start and Sell a Woodworking Business

Starting a woodworking business requires careful planning and execution. Here's a step-by-step guide to help you get started:

1. Business Plan:

Create a detailed business plan that outlines your niche, target market, budget, and business goals.

Define your unique selling points and value proposition.

2. Legal Considerations:

Register your business and obtain any necessary licenses or permits.

Consult with a legal professional to ensure compliance with local regulations.

3. Workspace Setup:

Design and organize your woodworking and laser engraving workspace for efficiency and safety.

Invest in essential tools and equipment, including your laser engraving machine, woodworking tools, and safety gear.

4. Sourcing Materials:

Establish reliable sources for quality wood and other materials you'll need for your projects.

Consider sustainable and eco-friendly options to appeal to environmentally conscious customers.

5. Product Development:

Develop a product line that aligns with your niche and market demand.

Experiment with designs, finishes, and customizations to set your offerings apart.

6. Pricing Strategy:

Conduct a thorough cost analysis to determine the pricing of your products.

Consider factors such as material costs, labor, overhead, and desired profit margins.

7. Marketing and Sales:

Create a brand identity that reflects your woodworking style and values.

Establish an online presence through a website or e-commerce platform.

Utilize social media and digital marketing to promote your products.

Attend local craft fairs, markets, and exhibitions to showcase your work and engage with potential customers.

Leverage word-of-mouth marketing through satisfied customers and referrals.

8. Customer Satisfaction:

Provide excellent customer service and consistently deliver high-quality products.

Collect and showcase customer reviews and testimonials to build trust and credibility.

9. Scaling Your Business:

As your business grows, consider strategies for scaling.

Explore the possibility of hiring employees or outsourcing certain tasks to meet increased demand.

Profitable Woodworking Projects

To make money with woodworking, it's essential to choose projects that are not only in demand but also offer a good profit margin. Here are some profitable woodworking project ideas:

1. Custom Furniture:

Craft custom tables, chairs, and cabinets tailored to your clients' specifications.

Offer unique and personalized designs.

2. Wooden Home Decor:

Create and sell decorative items like wooden signs, picture frames, and wall art.

These products are popular for gifting and interior design.

3. Wooden Toys:

Craft safe and eco-friendly wooden toys for children.

These items have a timeless appeal and can be sold online or in local markets.

4. Kitchen Accessories:

Produce items like cutting boards, utensils, and spice racks.

High-quality kitchen accessories are always in demand.

5. Outdoor Furniture:

Craft outdoor furniture like benches, picnic tables, and Adirondack chairs.

These items can be sold seasonally.

6. Wooden Jewelry:

Create unique wooden jewelry items like pendants, earrings, and bracelets.

These pieces often appeal to a niche market.

7. Woodworking Kits:

Package woodworking kits that allowallowing customers to assemble and finish their own wooden projects.Include comprehensive instructions and materials.

8. Custom Signage:

Produce custom signs for businesses, events, and homes.

Engraving technology can add intricate designs and personalization.

In Conclusion

Woodworking is a versatile and rewarding craft that can be transformed into a profitable business when combined with laser engraving technology. By offering unique, personalized, and high-quality wooden products, you can cater to a growing market of customers who appreciate craftsmanship and individuality. With a well-thought-out business plan, dedication, and a touch of creativity, you can embark on a woodworking journey that not only satisfies your passion but also turns wood into gold. Whether you're just starting or looking to expand your existing woodworking business, the potential for success is within your grasp. So, embrace the fusion of woodworking and laser engraving, and let your entrepreneurial spirit flourish.