Leather Engraving Techniques Compared: Which Method is Right for You?

Leatherwork has evolved over the centuries, and now, with the rise of modern tools and technologies, crafters can explore a variety of engraving methods to create beautiful, detailed designs. Whether you're handcrafting wallets, customizing journal covers, or designing intricate fashion accessories, the choice of engraving method significantly impacts the final product.

In this guide, we’ll walk through the main types of leather engraving techniques available, compare their benefits and drawbacks, and explore why diode laser engraving has become a go-to solution for leather artisans. We’ll also highlight how cutting-edge laser engraving technology is making leather crafting faster and more efficient than ever before.

What Are the Main Leather Engraving Techniques?

The most popular engraving techniques for leather crafting are:

1. Traditional Hand Engraving

2. Stamping and Burning

3. Laser Engraving – especially using diode laser engravers

Let’s dive deeper into each of these methods to understand their pros and cons.

1. Traditional Hand Engraving

Traditional hand engraving remains a beloved craft, especially among artisans who value the deep, rich texture it imparts to leather. This method involves moistening (or "casing") the leather, followed by carving designs using tools like swivel knives and bevelers.

Pros:

· Rich textures with a unique handmade feel, perfect for custom leather designs.

· Low initial tool cost; basic tools can be purchased inexpensively, making it a cost-effective option for hobbyists.

· Ideal for large artwork on vegetable-tanned leather, which is popular in traditional leatherwork.

Cons:

· Time-consuming process.

· Requires high manual skill and training.

· Not suitable for mass production or intricate designs that require precision.

2. Stamping and Burning

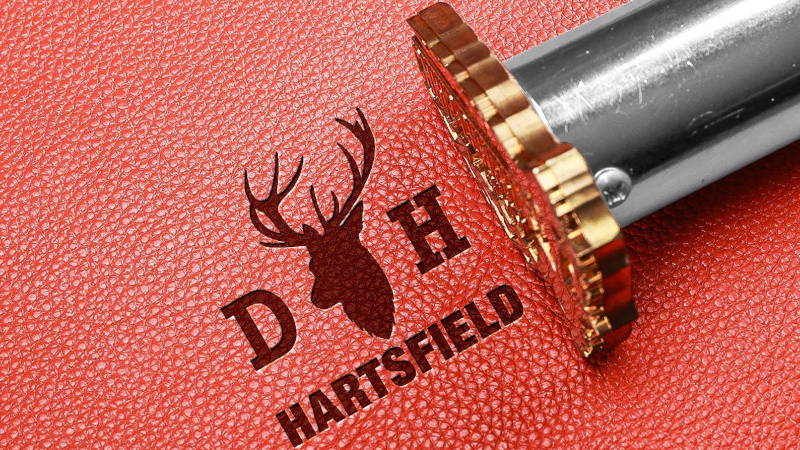

Stamping and burning are more accessible methods, often used by hobbyists and beginners. Stamping uses metal tools to press designs into the leather, while burning (or pyrography) involves using a heated pen to scorch the surface.

Pros:

· Affordable and beginner-friendly, ideal for crafters just starting out in leathercraft.

· Great for basic designs, monograms, and logos.

· Works well on natural leather tones such as cowhide and goatskin.

Cons:

· Limited ability to capture fine details.

· Not effective for synthetic leathers like vegan leather or faux leather.

· Burning can cause uneven coloration, especially in humid or dry climates, leading to inconsistent results.

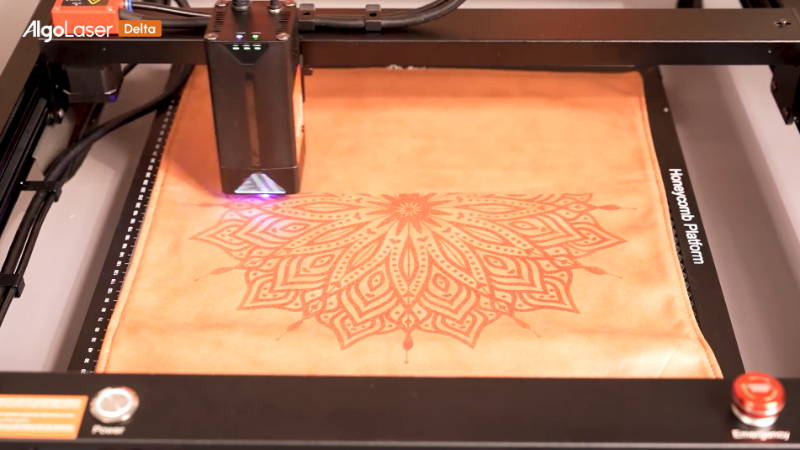

3. Diode Laser Engraving

Diode laser engraver has revolutionized the leathercraft industry. This method uses a focused light beam to engrave, burn, or cut leather with exceptional precision. Since there's no direct contact with the leather surface, it reduces material wear and tear.

Pros:

· Ultra-precise for detailed designs, even small text or intricate graphics.

· Fast and scalable, ideal for batch production.

· Dual-purpose: engraving and cutting leather with one machine, making it a versatile tool for custom leather goods.

· Works on various leather types and thicknesses, making it versatile for a wide range of projects, from wallets to accessories.

Cons:

· Higher initial investment for equipment, especially diode laser engravers.

· Requires proper ventilation due to smoke and fumes generated during the engraving process.

· A learning curve with design software like LightBurn or LaserGRBL.

What Types of Leather Can Be Engraved?

Not all leather is created equal, and different types respond better to different engraving techniques:

| Leather Type | Compatible Methods | Notes |

|---|---|---|

| Vegetable-Tanned | All techniques | Best for hand tools and laser engraving |

| Chrome-Tanned | Laser engraving, burning | May emit fumes; ventilation required |

| Suede | Stamping, light laser engraving | Soft texture, details may blur |

| Faux/Synthetic | Laser engraving (low power) | Risk of melting; test on small areas first |

Comparing Leather Engraving Techniques

Let's break down how these three methods stack up in real-world use:

| Technique | Precision | Ease of Use | Speed | Cost | Customization | Leather Cutting |

|---|---|---|---|---|---|---|

| Hand Engraving | Medium | Low | Slow | Low | High | No |

| Stamping & Burning | Medium | Medium | Medium | Low | Medium | No |

| Diode Laser Engraving | Very High | High | Fast | Medium | Very High | Yes |

Diode Laser Engraving: The Modern Leather Crafter's Secret Weapon

For professional-grade precision, speed, and versatility, diode laser engraving is becoming the preferred choice among leather artists. Machines like the AlgoLaser Alpha MK2 bring industrial-level capabilities to your home or workshop. Whether you're engraving detailed patterns, logos, or performing clean leather cutting, diode lasers provide consistent, sharp results with minimal material waste.

Why Choose a Diode Laser?

· Pinpoint detail: Perfect for logos, typography, and complex patterns.

· Dual functionality: Engrave and cut leather with one machine, making it ideal for custom leather goods.

· Repeatability: Great for batch production, whether you're running a small business or scaling up your production.

· Time-saving: Tasks that once took hours by hand are now completed in minutes, boosting productivity.

With design software like LightBurn, you can bring any image to life directly on leather—no hand tracing needed. This tech-driven process opens new creative possibilities for artisans.

Leather Cutting with a Laser Engraver

One of the surprising benefits of a diode laser engraver is its ability to cut leather with precision. Whether you're designing custom wallet templates or intricate jewelry shapes, a laser cutter can slice through most natural leathers, making it an excellent tool for crafting leather accessories.

Leather Cutting Tips

Use air assist to blow away debris and reduce burn marks for a cleaner finish.

Apply masking tape to prevent edge charring, particularly important for delicate leather projects.

Adjust power and speed settings based on the thickness of leather you are using.

Always test cuts on small samples before starting large-scale production.

Which Leather Engraving Method Should You Use?

· Traditional hand engraving: Best for those who value texture and artistry, and don’t mind investing time and skill in each piece.

· Stamping and burning: Great for beginners who are looking to create simple, personalized leather designs without major investment in equipment.

· Laser engraving : Ideal if you want detailed designs, fast turnaround, and the flexibility to cut leather as well. Perfect for small businesses and crafting professionals.

Final Thoughts

While traditional methods will always have a place in artisanal leatherwork, diode laser engraving has opened up new opportunities for precision, speed, and versatility. Whether you're designing one-of-a-kind gifts or running a small product line, laser engraving can make your process more efficient and your designs more consistent. The added bonus of laser cutting further enhances the creative possibilities for leather artisans.

Ready to take your leather crafting to the next level? A diode laser engraver might be just what you need to elevate your leather projects.

- Choosing a selection results in a full page refresh.