How to Laser Engrave Stones

Stone engraving is an ancient and revered art form that has been practiced across different cultures for millennia. It involves carving or etching designs, patterns, and text onto stone surfaces, transforming seemingly ordinary rocks into works of enduring beauty and historical significance. The art of stone engraving is not only a testament to human creativity but also a bridge connecting the past with the present.

Laser engraving on stones is a fascinating and versatile technique that has gained immense popularity in recent years. It involves using laser technology to etch or engrave designs, patterns, and text onto various types of stone surfaces. This modern method of stone engraving offers unparalleled precision and detail, making it an ideal choice for creating stunning personalized gifts, artistic masterpieces, and lasting memorials.

In this article, we will explore the comparison between different stone-engraving methods, discuss the different types of stone laser engraver machines available and the factors needed to consider when choosing the best laser engraving stone machine and introduce the step-by-step process for making charming stone laser engraving works. We'll also share various glass-making craft ideas for you that may be helpful to your engraving business. Let us get started.

Different Methods of Stone Engraving

One of the remarkable aspects of stone engraving is the diversity of methods that can be employed. These methods range from traditional, labor-intensive techniques to modern, high-precision technologies. Each method has its unique advantages and characteristics.

Traditional Hand Engraving: Hand engraving is the most ancient form of stone engraving. It uses hand tools like chisels and mallets to carve designs into the stone. This method requires exceptional skill and patience, resulting in intricate and highly detailed engravings. It is often used in creating historic markers, headstones, and memorial monuments.

Sandblasting: Sandblasting employs high-pressure air and abrasive materials to etch designs onto the stone surface. It is known for its ability to create deep and precise engravings, making it suitable for intricate designs and text. Sandblasting is widely used for artistic applications, memorials, and architectural stone features.

Diamond Point Etching: This method uses specialized rotary tools with diamond-tipped bits to etch the stone. It provides exceptional precision and is well-suited for fine details and lettering. Diamond point etching is commonly used for creating custom plaques and decorative stone pieces.

Laser Engraving: Modern technology has introduced laser engraving as a highly efficient method. Laser machines use focused laser beams to remove material from the stone's surface, allowing for incredible precision and speed. This method is versatile and can be applied to a wide range of projects, from personalized gifts to intricate art pieces.

Chemical Etching: Chemical etching involves using chemical solutions to etch the stone's surface. It is a method that is often used for creating subtle, tone-on-tone engravings on stones. This technique is favored for its subtlety and is commonly applied in artistic and decorative pieces.

Stencil and Paint Method: This method combines stencils and paint to create designs on stone surfaces. It is a versatile approach that can be used to create colorful, visually striking engravings, making it popular for signage and decorative applications.

The significance of using various methods in stone engraving is that it allows artists, craftsmen, and creators to tailor their approach to the specific requirements of each project. Traditional methods provide a timeless and artisanal touch, while modern technologies offer precision and efficiency. By employing a diverse range of techniques, stone engravers continue to honor the art's rich history while pushing the boundaries of what is achievable in the present day. Whether to commemorate historical events, celebrate personal milestones, or create stunning art, stone engraving remains an enduring and dynamic artistic practice.

The Advantage Of Laser Engraving Stone

Laser engraving is a cutting-edge technology that has transformed the art of stone engraving. Whether for personal or commercial use, the advantages of laser engraving on stone are numerous and impactful. Below, we explore these advantages in more detail:

1. Precision and Detail

Laser engraving offers an unprecedented level of precision and detail. The focused laser beam can etch intricate designs, text, and patterns with remarkable accuracy, resulting in sharp and finely detailed engravings. This precision is challenging to achieve through traditional stone engraving methods.

2. Durability

Engravings created with lasers on stone are exceptionally durable. The laser physically alters the stone's surface, ensuring the design remains intact, even in harsh conditions. This durability makes laser-engraved stones ideal for outdoor applications, such as memorials or architectural elements.

3. Versatility

Laser engraving can be applied to a wide array of stone types, from soft ones like limestone to hard ones like granite. This versatility opens up a world of possibilities for artistic, architectural, and commercial projects, from custom sculptures to headstones and signage.

4. Clean and Sharp Results

Laser engraving on stone yields clean, sharp, and well-defined results. There's no need for additional materials like inks or chemicals, eliminating the risk of smudging or fading over time. The final product boasts a professional and polished appearance.

5. Customization

Laser engraving allows for a high degree of customization. Names, dates, intricate designs, and even photographs can be etched onto stones, making them perfect for personalized gifts, memorials, or monuments. Businesses can also use this capability to incorporate their logos or branding into stone products.

6. Efficiency

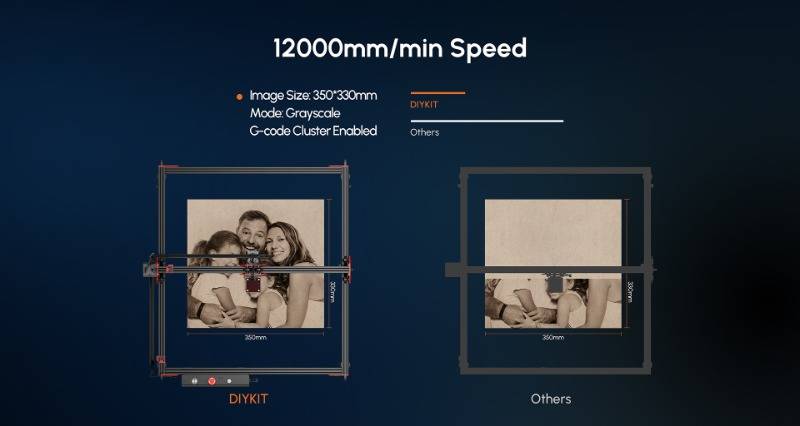

Laser engraving is a highly efficient process. The laser operates swiftly and accurately, reducing production time and enabling large quantities of stone items to be engraved in a shorter timeframe. This efficiency is invaluable for both individual and commercial applications.

7. Non-Invasive Process

The laser engraving process is non-invasive, meaning it doesn't require direct contact with the stone's surface. This ensures the integrity and quality of the stone are preserved during the engraving process.

8. Environmental Friendliness

Laser engraving is an eco-friendly option. It doesn't involve the use of harmful chemicals or materials that could harm the environment, making it a clean and responsible choice for stone engraving projects.

Above all, laser engraving on stone is a modern marvel that offers unparalleled precision, durability, and versatility. It empowers artists, businesses, and individuals to bring their visions to life, creating stone engravings that stand the test of time. Whether it's for personal memorabilia, artistic expression, or architectural enhancements, laser engraving on stone provides an exceptional means of transforming a solid, unyielding material into a canvas for artistic and functional masterpieces.

Search on Stone Laser Engraving Machines

Laser engraving on stone has seen a remarkable evolution with the advent of different laser machine types. Among the most prominent are CO2, fiber, and diode lasers. Understanding the distinctions and applications of these laser machines is crucial for choosing the right tool for your stone engraving needs.

CO2 Lasers

CO2 lasers are one of the most commonly used machines for stone engraving. They operate by exciting a mixture of carbon dioxide, nitrogen, and other gases to produce a laser beam. These lasers are exceptionally versatile and can engrave a wide range of stone materials, from granite and marble to slate and engineered stones. CO2 lasers excel in carving intricate designs and text, making them a preferred choice for artistic and decorative stone engravings. They are highly efficient and produce detailed results, often used for personalized gifts, memorials, and ornamental pieces.

Fiber Lasers

Fiber lasers are renowned for their precision and ability to deliver high-contrast engravings. These lasers are primarily used for marking or engraving on metals, but they can also be applied to select stone surfaces, primarily dark-colored stones. Fiber lasers stand out for their capacity to create sharp, dark etchings on stone, making them suitable for detailed artwork and text on specific stone types. While their use in stone engraving is limited compared to CO2 lasers, they play a crucial role in achieving high-contrast designs.

Diode Lasers

Diode lasers are the most compact and portable among the laser types. They are mainly used for engraving on softer stones. Besides, High-wattage diode laser engravers, like AlgoLaser Alpha and AlgoLaser Delta, can be used on a wide range of stone types, from softer ones like soapstone and ceramics to harder materials like granite and marble. Their ease of use and affordability make them a popular choice for hobbyists and small-scale stone engraving applications.

In summary, a deeper understanding of the types of laser machines for stone engraving reveals that the choice of laser type is pivotal to the success of the engraving project. The type of stone, the desired level of detail, and the intended application all influence the choice of laser machine. Each laser type offers a unique set of advantages and is tailored to specific engraving needs, whether for artistic, commercial, or personal use.

Choosing the Best Stone Laser Engraving Machine

Selecting the appropriate laser machine for stone engraving is a critical decision that significantly influences the success of your project. Several factors should be taken into consideration to ensure that the chosen machine aligns perfectly with your specific project requirements.

1. Laser Type

The first decision to make is the type of laser to use. Common options include CO2, fiber, and diode lasers. Each type has its unique characteristics, and the choice depends on factors such as the type of stone, the level of detail required, and the desired application. CO2 lasers are versatile and suitable for various stone types, while fiber lasers excel in high-contrast engravings on dark-colored stones. Low-watt diode lasers are ideal for softer stones, and high-watt diode lasers are also suitable for harder ones.

2. Power and Wattage

The power and wattage of the laser machine are crucial considerations. Higher-wattage machines are capable of faster engraving and can cut through thicker stone materials. The choice of power depends on the intended use. For intricate designs and fine details, lower wattage may suffice, while high-wattage lasers are suitable for larger, commercial projects.

3. Workspace and Bed Size

The size of the machine's workspace or bed determines the maximum stone size that can be engraved. It's essential to choose a machine with a bed size that accommodates your intended projects. Larger beds are suitable for more extensive engravings or engraving multiple smaller pieces simultaneously.

4. Precision and Resolution

The precision and resolution of the laser machine affect the level of detail achievable in the engravings. Higher-resolution machines provide greater detail and clarity, making them ideal for intricate designs and fine text. If your project requires fine, detailed engravings, opt for a machine with higher resolution capabilities.

5. Software and Compatibility

The software used to control the laser machine is vital. It should be user-friendly and compatible with your design software. Ensure that the software can import various file formats, as this affects the ease of designing and transferring your projects to the laser machine.

6. Cooling and Ventilation

Laser engraving generates heat and fumes, which must be managed effectively to prevent damage to the machine and ensure safety. A machine with an efficient cooling and ventilation system is essential, particularly for prolonged use.

7. Maintenance and Support

Consider the maintenance requirements of the laser machine. Look for machines with a reputation for reliability and minimal downtime. Additionally, access to technical support and training is essential for addressing any issues or optimizing your machine's capabilities.

8. Budget

Your budget is a significant factor in choosing the right laser machine. Different laser machines come at varying price points, and it's crucial to balance your project requirements with your budget constraints.

Selecting the right laser machine for stone engraving requires careful consideration of laser type, power, bed size, precision, software, cooling, maintenance, and budget. Matching the machine to your specific project needs ensures that you achieve the desired results efficiently and effectively, whether you're working on artistic creations, commercial projects, or personal memorabilia.

Types of Stone Suitable for Laser Engraving

Laser engraving is a versatile technology that can be applied to various stone materials, but some stones are better suited for this process due to their characteristics. Here are some types of stones commonly used for laser engraving:

1. Granite

Granite is one of the most popular stones for laser engraving due to its durability and versatility. It comes in various colors and patterns, allowing for a wide range of design possibilities.

2. Marble

Marble is known for its elegant appearance and smooth surface. It engraves beautifully, creating a high-contrast result for detailed designs and text.

3. Slate

Slate is often used for laser engraving because of its dark color and fine-grained texture. It provides a sharp, high-contrast appearance, making it suitable for decorative items and signage.

4. Basalt

Basalt is a volcanic rock with a dark color and fine grain. It's an excellent choice for laser engraving, offering clear and detailed results.

5. Limestone

Limestone is a softer stone that can be engraved with intricate designs and text. It has a lighter color compared to other stones, which can create a unique aesthetic.

6. Sandstone

Sandstone has a distinctive, grainy texture that can add character to engravings. It works well for artistic projects, although it may not offer the same level of detail as harder stones.

7. Soapstone

Soapstone is a soft stone that's easy to work with, making it suitable for beginners. It engraves well and can be used for artistic and decorative purposes.

8. Ceramic Tiles8. Ceramic Tiles

While not a traditional stone, ceramic tiles are often used in laser engraving due to their suitability for detailed designs and patterns. They come in various colors and finishes.

By selecting the right stone type and following the proper cleaning and preparation steps, you can achieve stunning, detailed laser engravings that enhance the beauty and durability of the stone material.

How the Laser Engrave on Stone

Laser engraving on stone is a precise and versatile process that can yield stunning results. The process involves a series of steps, from selecting the right settings to post-processing for a polished final product. Here's a step-by-step overview of the stone laser engraving process:

1. Material Selection

Begin by choosing the appropriate stone material for your project. Common stones for laser engraving include granite, marble, slate, and more. The choice of stone should align with your design, intended application, and desired appearance.

2. Machine Setup

Set up the laser engraving machine, ensuring that it is properly calibrated. This includes aligning the laser's focus and adjusting the bed height to accommodate the stone's thickness.

3. Design and Software

Design your artwork or text using graphic design software. Save the design in a format compatible with the laser engraving machine's software. Import the design into the machine's software, where you can adjust its position and size on the stone.

4. Cleaning and Masking

Thoroughly clean the stone surface to remove any dust, dirt, or oils. After cleaning, consider applying masking material to protect certain areas of the stone that should not be engraved. The masking material will help maintain a clean surface.

5. Laser Parameters

Configure the laser settings to match the stone type and the intricacy of your design. Factors to consider include:

Power: This setting controls the intensity of the laser beam. Harder stones may require higher power levels, while softer stones need lower power. Experiment to find the right balance for your project.

Speed: Speed determines how quickly the laser moves over the stone's surface. Faster speeds may be suitable for light engravings, while slower speeds allow for deeper, more pronounced engravings.

Frequency (Pulse Rate): Frequency settings control the number of laser pulses per second. Higher frequencies can improve the engraving's appearance, especially for complex designs.

6. Focusing the Laser

Ensure that the laser beam is properly focused on the stone's surface. Precise focusing is essential for achieving sharp and detailed engravings.

7. Engraving Process

Start the engraving process, and the laser will follow the design's path, removing a thin layer of material from the stone as it goes. The heat generated by the laser vaporizes the stone's surface, creating the engraved pattern or text. The duration of the engraving process will depend on the stone type, design complexity, and the selected power and speed settings.

8. Post-Processing

After the engraving is complete, remove any masking material. Clean the stone to remove any residual dust or debris from the engraving process. Depending on the stone type and your project, you may choose to apply a finish, such as polishing or sealing, to enhance the appearance and durability of the engraving.

9. Inspection and Quality Control

Carefully inspect the engraving to ensure it meets your quality standards. Verify that the engraving is sharp, detailed, and free from defects.

By following these steps and adjusting the laser parameters to suit the specific stone type and design, you can create remarkable laser engravings on various stones, adding a touch of artistry and personalization to a wide range of applications, from memorials and architectural elements to decorative items and personalized gifts.

Popular Stone Laser Engraving Projects and Ideas

Stone laser engraving is a versatile and artistic process that lends itself to a wide range of creative projects. Here are some popular stone laser engraving ideas and projects:

1. Memorial Plaques and Headstones

Create elegant and lasting memorial plaques with engraved names, dates, and touching quotes.

Craft personalized headstones to honor and remember loved ones with unique designs and symbols.

2. Decorative Signage

Design custom stone signage for homes, businesses, or events. Engrave family names, addresses, or business logos for a stylish and enduring impression.

Add a touch of sophistication to gardens or entrances with engraved stone house number signs.

3. Personalized Gifts

Make unique and cherished gifts by engraving names, special messages, or photos on stone items like coasters, wine racks, or cutting boards.

Personalized stone jewelry, including pendants, bracelets, or keychains, adds a personal touch to gift-giving.

4. Architectural Elements

Enhance architectural elements with engraved stone, such as fireplaces, fountains, or entryway features.

Use engraved stone columns, balusters, or wall panels to elevate the visual appeal of interior and exterior designs.

5. Artistic Creations

Produce captivating stone artwork with intricate designs, patterns, or abstract compositions.

Utilize different stone types to create texture and depth in sculptures, wall art, or decorative pieces.

6. Wedding and Event Decor

Add a touch of elegance to weddings and special events with engraved stone centerpieces, table numbers, or event signage.

Create unique wedding favors by engraving the couple's names and wedding dates on small stone items like heart-shaped stones or magnets.

7. Customized Coasters and Trivets

Design stone coasters or trivets with personalized engravings, making them practical and decorative additions to any home.

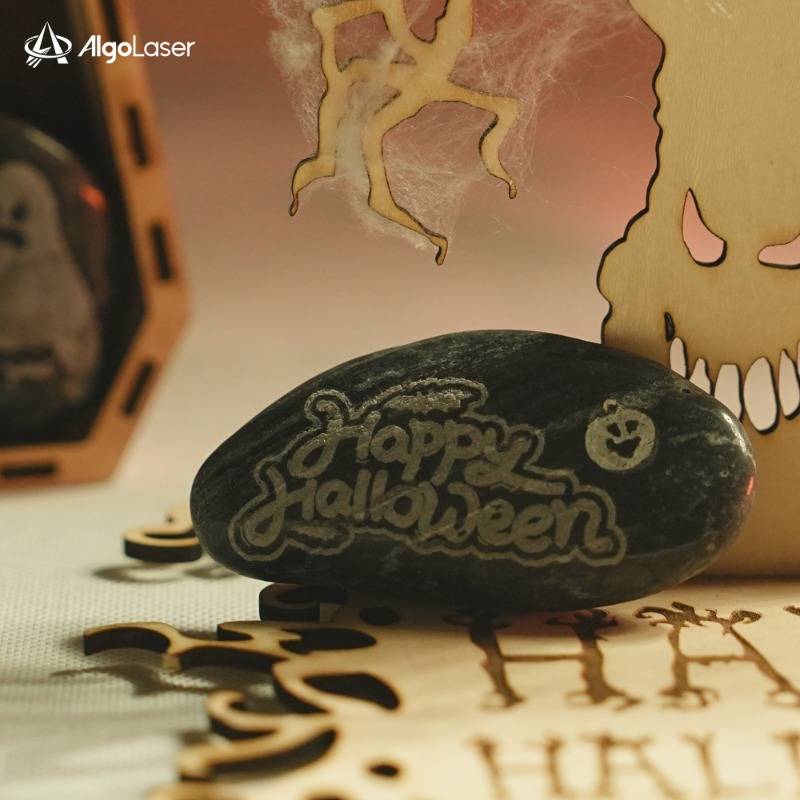

Create thematic sets for holidays or special occasions, such as Halloween, Christmas, or weddings.

8. Garden Stepping Stones

Personalize garden pathways with engraved stone stepping stones, featuring names, inspirational quotes, or whimsical designs.

Engraved stones can also serve as memorial markers for cherished pets or garden dedications.

9. Pet Memorials

Commemorate beloved pets with engraved stone markers that include names, dates, and endearing messages.

Add paw prints, images of pets, or favorite sayings to create personalized pet memorials.

These ideas showcase the versatility and personalization possibilities of stone laser engraving, making it a favored choice for commemorating loved ones, enhancing spaces, and creating unique and meaningful gifts.

image credit: SoleBayCrafts - Etsy

Conclusion

Stone laser engraving unveils a world of artistry and craftsmanship where nature's canvas meets cutting-edge technology. It's a journey through time, as old as the stones themselves, yet filled with endless possibilities.

The laser beam dances across the stone's surface, meticulously etching your designs. It's here that you can breathe life into your imagination, creating intricate patterns or paying tribute to cherished memories. The stone becomes a canvas for your creativity.

The world of stone laser engraving is an invitation to explore, learn, and craft beauty. So, we encourage you to embrace this artistic journey. Experiment, create, and let the stones tell your unique story. The world is waiting to see the beauty you'll unveil in every engraved piece.

Free SVG & Gcode Files for Laser Engraving & Cutting can be found here, wich you can import into our laser cutters directly.

- Choosing a selection results in a full page refresh.