How To Laser Engrave Leather With The Best Laser Engraver

Leather, known for its timeless elegance and versatility, has been a canvas for artistic expression for centuries. The beauty of leather, with its rich texture and natural grain, makes it a preferred choice for fashion, accessories, and home decor. While the art of handcrafting intricate designs on leather has a longstanding tradition, modern technology has introduced a new dimension to this craft through laser engraving.

Laser engraving on leather has revolutionized the way we decorate, personalize, and embellish leather products. It offers precision, consistency, and versatility that manual methods struggle to match. Whether it's customizing leather wallets, or belts, or adding intricate designs to leather furniture, laser engraving brings innovation to this timeless material.

In this exploration of laser engraving on leather, we will delve into the various aspects of this technology, including its applications, techniques, and creative possibilities. Whether you're an artisan, a designer, or simply a lover of leather goods, laser engraving on leather opens up a world of creative opportunities. This technology combines tradition with innovation, resulting in products that are not just functional but also visually captivating.

The Way of Leather Engraving

Carving on leather is a creative and artistic craftsmanship, with several different methods used for engraving. Here are a few common leather carving methods:

1. Knife Carving

Knife carving is one of the most common methods of leather carving. It involves using special leather carving knives, blades, or gouges to engrave patterns, textures, or text onto the leather. Knife carving can create very fine lines and details.

2. Stamping

Leather stamping is a method for imprinting patterns onto the leather. This typically involves using rubber stamps, wooden stamps, or metal stamps to create repetitive patterns. It is a method suitable for the production of leather goods.

3. Engraving Machines

Engraving machines are mechanical devices that can engrave precise designs or text onto leather-based on computer programs or manually input designs. This method is suitable for large-scale production and projects that require high precision.

4. Embossing

Embossing involves using special embossing tools to press patterns and designs onto leather. This can create a three-dimensional effect and result in raised and recessed textures on the leather.

5. Dyeing

In addition to physical carving, you can also use leather dyes or painting tools to create patterns and textures on leather. This method typically requires more artistic skills and can be used for intricate designs.

6. Burnishing

Burnishing is a method that uses heat tools, such as a burnishing pen, to engrave patterns on leather. By controlling the tool's temperature and duration, different depths of engraving can be achieved on the leather.

7. Tack Carving

Tack carving is a method of printing patterns and textures onto leather. It involves using specialized tools and some techniques to create imprints on the leather.

Each of these methods has its unique characteristics and can be chosen based on your project requirements and skill level. Regardless of the method you choose, practice and patience are needed to achieve outstanding carving results.

The Advantage of Leather Laser Engraving

Laser engraving on leather has gained popularity for several compelling reasons. Here are some of the advantages of choosing a laser engraving machine for leather:

Precision and Detail: Laser engraving offers unparalleled precision, allowing for intricate details and fine lines that are challenging to achieve with traditional methods. This is especially valuable when working on small or complex designs.

Consistency: Laser technology ensures consistent results across multiple leather pieces or production batches. Each item is engraved with the same precision and accuracy, which is crucial for mass production and maintaining quality.

Versatility: Laser engraving is incredibly versatile and can be used for a wide range of leather products, from wallets and belts to footwear and accessories. It accommodates various leather types, including full-grain, top-grain, and suede.

Customization: Laser engraving enables easy personalization of leather goods. Whether it's adding names, dates, or custom designs, this technology allows for tailored and unique products.

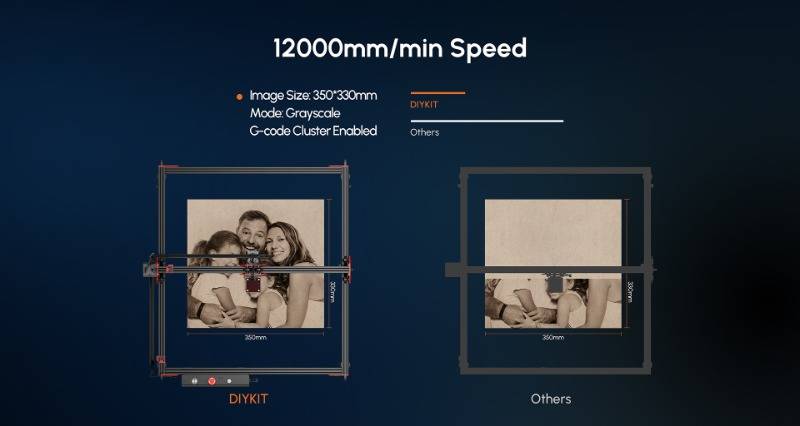

Speed: Laser engraving machines work relatively quickly, making them suitable for large-scale production. They can significantly increase production efficiency and reduce lead times.

Non-Contact Process: Laser engraving is a non-contact process, meaning the leather's surface remains undisturbed. It doesn't compromise the leather's texture, softness, or durability, ensuring the quality of the material.

Durability: Laser-engraved designs are long-lasting and highly resistant to wear and tear. The engraved pattern won't fade or wear off over time, ensuring a lasting, high-quality finish.

Wide Range of Effects: Laser engraving machines can create a variety of effects, including deep engraving, shallow engraving, cutting, and surface marking. This versatility allows for diverse design possibilities.

Automation: Laser engraving can be controlled via computer software, making it easy to replicate designs and make adjustments. This automation reduces the chances of human error and enhances efficiency.

Environmental Considerations: Laser engraving is an eco-friendly option as it typically uses less energy and produces minimal waste compared to some other processes.

Complex Designs: Laser technology can handle intricate and complex designs with ease, making it suitable for highly detailed artwork and patterns.

Minimal Maintenance: Laser engraving machines are known for their reliability and require minimal maintenance, leading to lower operating costs.

In summary, laser engraving on leather offers exceptional precision, consistency, and versatility. It allows for customization, is efficient for large-scale production, and is environmentally friendly. These advantages have made it a preferred choice for those looking to enhance the beauty and quality of leather products through engraving.

How the Laser Engraving Machines Work on Leather

Leather laser engraving machines have become indispensable tools for artisans and manufacturers alike. They offer an efficient and precise way to add intricate designs, logos, or text to leather products while maintaining the material's integrity. In this part, we will delve into the workings of leather laser engraving machines and explore the types of lasers best suited for this application.

How Leather Laser Engraving Machines Work

Principles: Laser engraving machines are devices that utilize a high-energy laser beam to engrave or cut the surface of materials. In the context of leather engraving, the operating principles of laser engraving machines are as follows:

Laser Generating: Laser systems generate a highly focused laser beam, typically employing CO2 lasers, fiber lasers, or diode lasers. These lasers emit beams with high energy capable of rapidly heating and vaporizing materials.

Laser Focusing: The laser beam is focused through a lens, concentrating its energy on a very small area, ensuring high precision and efficient engraving.

Material Interaction: The laser beam interacts with the surface of the leather, causing rapid heating of the material, resulting in evaporation, gasification, or combustion, thereby forming the desired patterns or text. The laser engraving machine can rapidly and accurately engrave different areas based on the design's instructions.

Automatic Control: The movement of the laser engraving machine is computer-controlled, enabling automatic engraving based on pre-set designs. This eliminates human errors and ensures consistency and high-precision engraving.

Types of Lasers for Leather Engraving

CO2 Lasers: Carbon dioxide lasers are the most commonly used for leather engraving. They produce a high-powered beam that efficiently vaporizes the material, making them versatile for a wide range of leather types. They are particularly adept at creating contrasting and deep engravings.

Fiber Lasers: Fiber lasers are known for their high precision and are ideal for engraving fine details on leather. They work by pulsing a laser through optical fibers, producing a concentrated beam that can achieve intricate patterns with exceptional clarity.

Diode Lasers: Diode lasers are compact and energy-efficient, making them suitable for smaller leather engraving machines. While they may not be as powerful as CO2 or fiber lasers, they are still effective for engraving text and simple designs on leather.

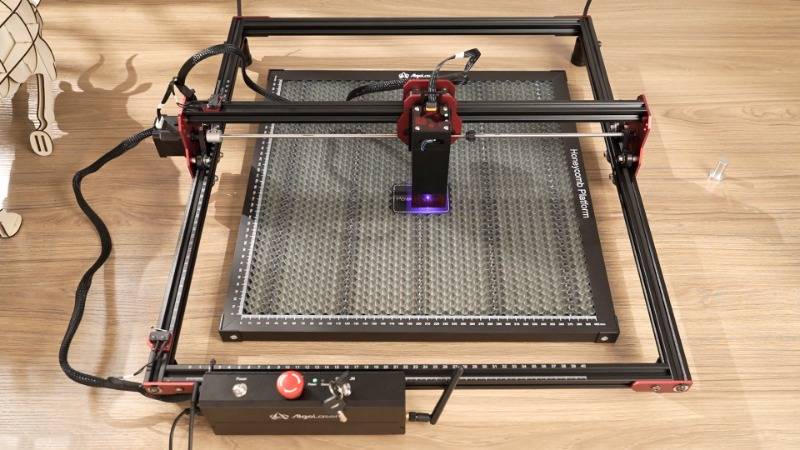

Choosing the Best Leather Laser Engraving Machines

When it comes to choosing the best leather laser engraving machine, several crucial factors should be considered to ensure that the investment meets your specific needs and delivers optimal results. Here are the key considerations to keep in mind when purchasing a leather laser engraving machine:

Laser Type: The type of laser is a fundamental consideration. CO2 lasers are versatile and suitable for various leather types. Fiber lasers excel at fine, detailed engraving, while diode lasers are more compact and energy-efficient. Assess your engraving requirements to determine which laser type best aligns with your needs.

Engraving Area: Evaluate the size of the engraving area, as it dictates the maximum dimensions of the leather pieces you can work with. Ensure that the machine's work area accommodates the size of the leather products you intend to engrave.

Laser Power: Laser power affects the depth and speed of engraving. Higher-power lasers can achieve deeper engravings and often work more quickly. Consider the thickness and density of the leather materials you plan to engrave when selecting the laser power.

Software Compatibility: The machine's software is crucial for design input and control. Ensure that the engraving machine is compatible with the design software you intend to use. User-friendly software can significantly impact the ease of operation and design flexibility.

Speed and Accuracy: Look for a machine that offers a good balance between engraving speed and accuracy. High-speed machines are efficient for mass production, while high-accuracy machines are essential for intricate and detailed designs.

Maintenance Requirements: Consider the maintenance needs of the machine. Some machines require more frequent servicing and upkeep than others. Low-maintenance machines can save time and operating costs in the long run.

Cooling System: Laser engraving generates heat, and a reliable cooling system is essential to prevent overheating. Ensure that the machine has an effective cooling system to maintain consistent performance.

Safety Features: Laser engraving involves high-energy lasers, so safety features are paramount. Look for machines with safety interlocks, emergency stop buttons, and proper ventilation to protect operators from potential hazards.

Price and Budget: Determine your budget for the machine, including any necessary accessories or additional features. Consider the long-term value of the machine and its potential return on investment.

Customer Support and Training: Research the manufacturer's reputation for customer support and after-sales service. Training and technical support can be invaluable, especially for those new to laser engraving technology.

User Reviews and Recommendations: Seek out user reviews and recommendations to gain insight into the experiences of others who have used the same machine. This can help you make an informed decision.

Choosing the appropriate tool depends on personal experience and preference. While hand engraving tools, like rotary cutters, can be fulfilling options for those who enjoy handcrafted arts and crafts, a laser engraver is ideal for beginners and entrepreneurs looking to start a business. It can be considered the easiest way to get started. Taking these factors into account will ensure that the machine you choose meets your specific engraving needs and provides long-lasting value.

The Process of Laser Engraving on Leather

Laser engraving on leather is a precise and creative process that can produce stunning results. This step-by-step guide provides a detailed walkthrough of the engraving process, including monitoring for proper execution and tips on achieving desired effects on leather.

Step 1: Design Preparation

Begin by designing or selecting the artwork or text you wish to engrave. Ensure that the design is in a format compatible with the laser engraving software, such as a vector graphic or a supported image format.

Step 2: Machine Setup

Position the leather material on the machine's work table, ensuring it is flat, smooth, and properly aligned. Adjust the laser head to the correct focal distance for the leather's thickness. Use the machine's alignment features to position the design accurately.

Step 3: Software Configuration

Input the design into the laser engraving software and set the parameters for the engraving. Customize settings such as laser power, engraving speed, frequency (PPI), and raster or vector mode, as per your design's requirements and the type of leather you are working with.

Step 4: Test Engraving

Before proceeding with the final engraving, it is recommended to perform a test run on a small area of the leather or a sample piece. This will allow you to assess the settings and make necessary adjustments to achieve the desired result.

Step 5: Execute the Engraving

Once satisfied with the test engraving, start the engraving process. The laser will follow the design's path, vaporizing or burning away the leather's surface as it moves. Monitor the machine during the process to ensure everything is running smoothly.

Step 6: Monitoring and Adjustment

Throughout the engraving, keep a close eye on the quality of the engraving. If you notice any inconsistencies or issues, be prepared to pause the machine using the emergency stop button and make necessary adjustments to the settings.

Step 7: Completion and Post-Processing

Once the engraving is complete, carefully remove the leather from the machine. Depending on the desired effect, you may want to apply finishing treatments to the engraved area. For instance, you can apply a leather conditioner to enhance contrast or a dye to add color to the engraved portions.

Tips for Achieving Desired Effects on Leather:

Experiment with Settings: Don't be afraid to experiment with laser power, speed, and frequency to achieve the right depth and texture for your design.

Vector and Raster Modes: Select the appropriate engraving mode (vector or raster) to achieve the desired outcome. Vector mode is ideal for crisp lines, while raster mode can create shading and detailed images.

Consider Material Variations: Different types of leather may yield different results. Experiment with various leather types to understand their engraving characteristics.

Texture and Depth: Adjust the laser settings to control the texture and depth of the engraving. Lower power settings may create a subtle texture, while higher power settings produce deeper engravings.

Material Pre-Treatment: Some leather may benefit from pre-treatment, such as applying a masking material or a light coat of spray to prevent charring or excessive discoloration.

Artistic Touch: Laser engraving allows for intricate details. Use this capability to create artistic and unique designs on your leather projects.

By following this detailed walkthrough and incorporating these tips, you can master the art of laser engraving on leather and achieve the desired effects to create beautiful and customized leather products.

Popular Leather Laser Engraving Projects and Ideas

Leather laser engraving and cutting provide a wealth of creative opportunities, allowing for the crafting of personalized gifts, intricate designs, and functional items. Moreover, laser-cut leather pieces can be used to craft intricate patterns and detailed designs, making it a popular choice for both artisans and those in search of one-of-a-kind accessories. Whether you're a leatherworking enthusiast or looking to create distinctive leather items, the realm of leather laser crafting offers a wide array of opportunities to explore and express your creativity. Here are some popular project ideas to inspire your next acrylic laser crafting endeavor:

1. Personalized Wallets

Engrave names, initials, or special messages on leather wallets to create unique and thoughtful gifts.

2. Custom Leather Belts

Add intricate patterns or personalized text to leather belts for a stylish and one-of-a-kind accessory.

3. Leather Keychains

Design and engrave leather keychains with names, dates, or meaningful symbols, perfect for gifts or promotional items.

image credit: EtchItUpDesigns - Etsy

4. Bracelets and Cuffs

Engraved leather bracelets and cuffs can feature intricate patterns, coordinates, or personal mottos.

5. Luggage Tags

Make luggage tags more distinctive by engraving your contact information, ensuring easy identification when traveling.

image credit: VdijkCloth - Etsy

6. Dog Collars

Personalized leather dog collars with engraved pet names or contact details are both stylish and practical.

7. Custom Leather Patches

Design and engrave leather patches for clothing, backpacks, or hats, creating branded or personalized items.

image credit: cjandcoshop1 - Etsy

8. Leather Earrings

Craft unique leather earrings with intricate patterns, shapes, and colors achieved through laser engraving.

9. Guitar Straps

Engrave decorative designs or musicians' names on leather guitar straps to add a personal touch to musical accessories.

image credit: Sweetcheeksaudio - Etsy

10. Cigar Cases

Personalized leather cigar cases with engraved initials or names make for distinctive gifts for cigar aficionados.

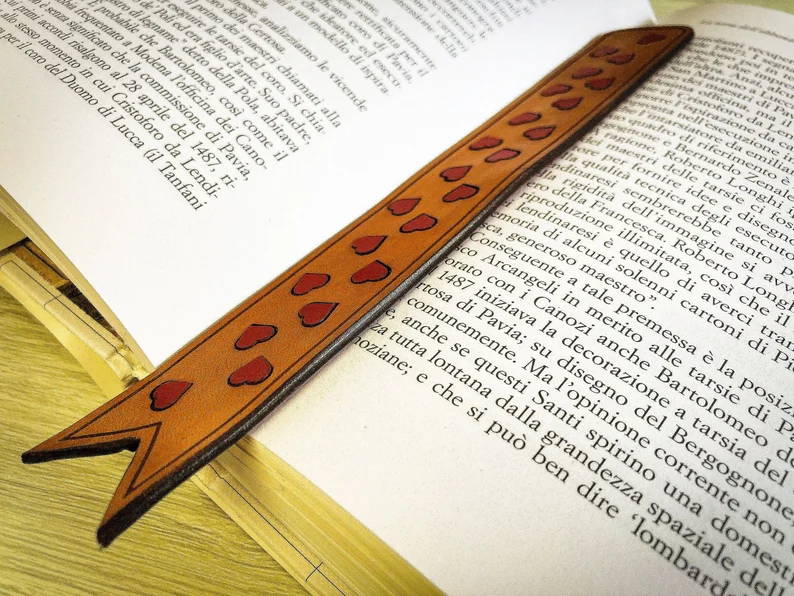

11. Bookmarks

Leather bookmarks with engraved inspirational quotes or personalized messages are excellent gifts for book lovers.

image credit: Albatros360 - Etsy

12. Wine Bottle Holders

Leather wine bottle holders with laser-engraved designs or monograms can add an elegant touch to gift presentations.

13. Badge Holders

Customize leather badge holders for events, conferences, or corporate use with engraved logos and names.

14. Personalized Footwear

Engrave leather shoes or boots with unique patterns, initials, or designs for a distinct fashion statement.

These popular leather laser engraving projects and ideas showcase the versatility of leather as a canvas for creative and meaningful customization. From stylish accessories to sentimental gifts, leather engraving offers endless possibilities for personalization and design.

Conclusion

In conclusion, leather laser engraving is a dynamic and versatile craft that opens up a world of creative possibilities. It allows for personalized gifts, intricate designs, and functional items. By engraving names, dates, or meaningful symbols, one can create heartfelt and unique leather products. The precise detailing and fine craftsmanship achievable through leather laser engraving make it an appealing choice for artisans and enthusiasts alike. We encourage our readers to explore this art, embrace innovation, and let their creativity flourish. With leather as their canvas and laser as their brush, there are no limits to what can be achieved.

- Choosing a selection results in a full page refresh.