How To Laser Engrave Glass With The Best Laser Engraver

Glass, with its transparent beauty and versatility, has become a canvas for artistic expression and functional design. Laser engraving on glass has gained immense popularity for its precision and ability to create intricate, permanent designs.

Glass engraving, or we can also call it glass etching. Both engraving and etching involve creating intricate designs, patterns, or images on the surface of glass objects. This delicate and precise technique transforms plain glass into pieces of art, where light and transparency become integral to the design. The main difference is the depth of laser penetration into the surface.

In this article, we will explore the definition of glass engraving, the advantages it offers over traditional methods, and the step-by-step instructions for making charming glass engraving works. We'll also share various glass-making craft ideas for you that may be helpful to your engraving business. If you are an experienced engraver, this article will provide you with a deeper understanding of laser engraving. For those who are new to the world of engraving, this article will unlock a new realm of possibilities.

The Advantage Of Laser Engraving Glass

Glass engraving can be achieved through various methods, each offering unique results. The traditional glass engraving methods are the following:

Diamond Wheel Engraving: In this traditional method, a rotating diamond-tipped wheel is used to cut into the glass surface. The artisan controls the depth and shape of the engraving by carefully manipulating the wheel.

Copper Wheel Engraving: Similar to diamond wheel engraving, but a copper wheel is used, resulting in a smoother finish.

Sandblasting: High-speed abrasive particles are propelled against the glass surface to create a frosted or textured effect. Stencils or masks can be used to create precise designs.

Laser engraving on glass offers a multitude of advantages, making it an increasingly popular choice for a wide range of applications. This precision technology has transformed the art of glass engraving, bringing forth benefits that extend beyond traditional methods. Below, we explore the many advantages of using laser engraving on glass.

1. Precision and Detail

Laser engraving is renowned for its unmatched precision and the ability to achieve intricate, detailed designs. The laser beam can create fine lines, tiny text, and complex patterns on glass surfaces with remarkable accuracy, even in three-dimensional engravings. This level of detail is difficult to replicate with other techniques.

2. Versatility

Laser engraving can be used on various types of glass, including clear, frosted, and colored glass. It's versatile enough to handle a wide range of glass products, from delicate glassware to robust architectural components.

3. Permanent Markings

One of the key advantages of laser engraving on glass is the permanence of the markings. The engraved designs are highly resistant to wear, fading, or damage, ensuring the longevity of the artwork or information. This makes it ideal for labeling and branding purposes.

4. Contactless Process

Laser engraving is a non-contact process, meaning that the glass surface remains intact and free from cracks or chips. This gentler approach preserves the structural integrity of the glass, even on fragile items.

5. Customization

Laser engraving offers a high degree of customization. Whether it's adding names, dates, or intricate artwork, the flexibility of laser engraving allows for personalized glass products. This makes it perfect for creating unique gifts and decorative pieces.

6. Speed and Efficiency

Laser engraving is an efficient process that can produce results quickly. It is precious in industrial applications where high-speed production is necessary.

7. Reduced Material Waste

Unlike some traditional methods, laser engraving generates minimal waste. It is an eco-friendly option for those concerned about sustainability.

8. Safety and Consistency

Laser engraving machines are equipped with safety features, making the process secure for both operators and the glass itself. The consistency of laser engraving ensures uniform results across multiple glass items.

Above all, laser engraving on glass offers a myriad of advantages, ranging from precision and permanence to customization and efficiency. Its versatility and ability to handle a wide range of glass products make it a valuable tool in various industries, from art and design to manufacturing and branding. As technology continues to advance, laser engraving on glass will likely remain at the forefront of the glass engraving art, providing countless opportunities for creativity and innovation.

Search on Glass Laser Engraving Machines

Glass laser engraving machines have revolutionized the art of engraving on glass surfaces. To gain a deeper understanding of these machines, it's essential to explore how they operate, the different types of lasers used, and the importance of laser parameters and features for glass engraving.

How Glass Laser Engraving Machines Operate

Glass laser engraving machines utilize the power of focused laser beams to create precise and intricate designs on the surface of glass. The process involves the following steps:

Focusing the Laser: The laser beam is focused on the glass surface using a lens. This ensures that the energy is concentrated on a specific point, allowing for detailed engraving.

Interaction with Glass: When the focused laser beam interacts with the glass, it heats the surface and, in some cases, causes controlled fractures or micro-explosions. This leads to the removal of tiny glass particles, resulting in the engraved pattern.

Movements and Control: The machine precisely controls the movement of the laser head, ensuring that the design is engraved accurately. The speed, power, and frequency of the laser can be adjusted to achieve different effects.

Differences Between Laser Types

Various types of lasers are used in glass engraving machines, with the two most common being CO2 lasers and fiber lasers. Besides, some diode laser engraving machines can also make glass-engraving craft in a particular process.

CO2 lasers produce infrared light with a wavelength that is well-absorbed by glass. They are suitable for engraving intricate patterns and text on glass.

Fiber lasers, on the other hand, emit a different wavelength and are often used for marking and etching on the glass surface.

The wavelength of a diode laser is typically not easily absorbed by glass. Therefore, to ensure optimal results when engraving glass with a diode laser engraver, it's necessary to apply a background or backing plate to the underside of the glass. This helps the laser to better absorb and form a pattern on the surface. The color of the backing plate can be either black or another hue.

Importance of Laser Parameters and Features

Several laser parameters and machine features are critical for successful glass engraving:

Power and Speed: Adjusting the laser power and engraving speed is essential. Higher power may be needed for deeper engravings, while slower speeds provide more detailed results.

Resolution: The machine's resolution determines the level of detail that can be achieved. Higher resolution allows for finer engravings.

Air Assist: Air assist is used to blow away debris and cool the glass surface during engraving, ensuring a cleaner finish.

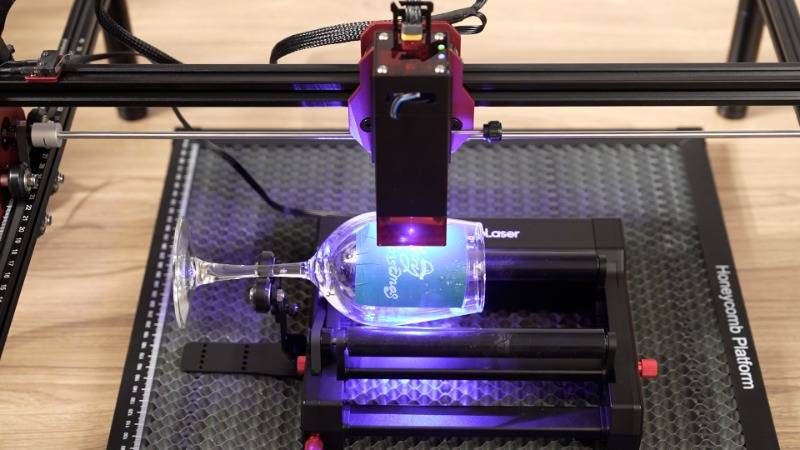

Rotary Attachment: For cylindrical objects like glassware, a rotary attachment is vital to ensure even engraving around the entire circumference.

Software Control: The software that controls the machine plays a significant role in the design and execution of engraving. It should be user-friendly and allow for customization.

Glass laser engraving machines operate by focusing laser beams on the glass surface, and the choice of laser type, as well as laser parameters and features, are crucial in achieving the desired engraving results. These machines have opened up new possibilities in glass art and industry, enabling precise and intricate designs that were once challenging to achieve through traditional methods.

Choosing the Best Glass Laser Engraving Machine

Selecting the right glass laser engraving machine is crucial for achieving your desired results. Whether you're a professional artist, a business owner, or an enthusiast, several key considerations can help you make an informed choice. This guide covers the factors to weigh when choosing a glass engraving machine and highlights a few top market picks. Considerations when selecting a glass engraving machine:

Accuracy: Precision is paramount when engraving on glass. Look for a machine that offers high accuracy in creating fine lines and intricate details. A laser engraving machine with a quality motion control system is essential to achieve the desired precision.

Power: The power of the laser is a critical factor. Higher-wattage lasers provide more versatility, allowing you to work on various glass types and achieve deeper engravings. For delicate glassware, lower-power lasers are preferable.

Size and Engraving Area: Consider the size and engraving area of the machine. This determines the maximum size of glass pieces you can work with. Ensure the machine's dimensions meet your project requirements.

Safety Features: Glass engraving machines should have safety features, such as interlocks, to protect users from the laser beam. Verify that the machine complies with safety standards and regulations.

Ease of Use: An intuitive user interface and user-friendly software are important for efficient operation. Consider machines with easy-to-navigate control panels and software that supports various file formats.

Air Assist and Ventilation: Proper ventilation is essential to remove fumes and debris produced during engraving. Machines with air assist systems help keep the work area clean and safe.

Before making a decision, carefully evaluate your specific needs and budget, and consider the factors mentioned above. Each machine has its strengths, and the best choice depends on your intended applications and requirements. With the right glass laser engraving machine, you can create stunning and intricate designs on glass surfaces with precision and finesse.

Types of Glass Suitable for Laser Engraving

Glass laser engraving can be applied to many glass materials, certain types are more suitable for laser engraving due to their composition and properties. Here are some glass types commonly used in laser engraving:

Borosilicate Glass: This type of glass is known for its durability and resistance to thermal shock. It is often used for scientific glassware, artistic glassblowing, and custom glass products.

Float Glass: Float glass, which is commonly used in windows and mirrors, is suitable for laser engraving. It produces a frosted or white mark when engraved, creating an elegant contrast.

Crystal Glass: Crystal glass is renowned for its clarity and brilliance. Laser engraving on crystal glass produces intricate and detailed designs, making it a popular choice for awards, trophies, and decorative items.

Colored Glass: Various types of colored glass, such as stained glass or tinted glass, can be laser engraved. The engraving contrasts beautifully with the glass's color, creating eye-catching results.

Optical Glass: Optical glass is used in lenses, prisms, and optical components. Laser engraving on optical glass can be highly precise and is often used for labeling or customization.

Tempered Glass: Tempered glass is known for its strength and safety properties. While laser engraving can be more challenging due to its toughness, it's possible with the right equipment.

Acrylic Glass (Plexiglass): While not traditional glass, acrylic is a transparent material suitable for laser engraving. It offers versatility and is often used for signage and artistic projects.

When considering laser engraving on glass, it's essential to choose the appropriate type of glass based on your specific application and desired results. Different types of glass will react differently to laser engraving, and understanding these characteristics is crucial to achieving the best outcomes.

The Process of Laser Engraving on Glass

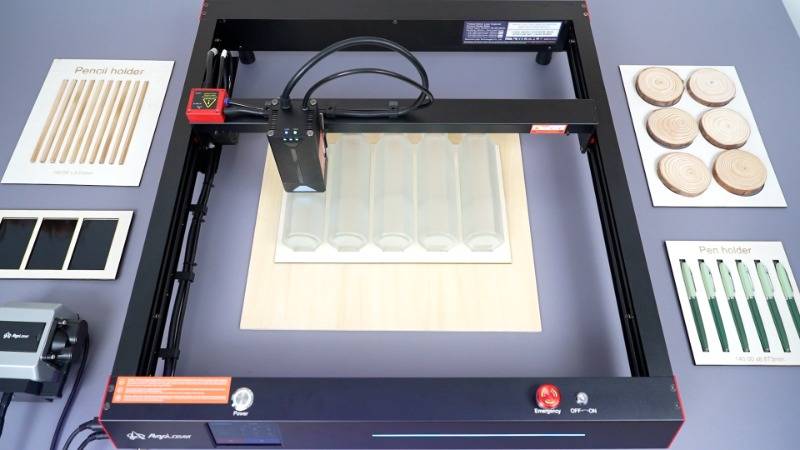

Glass laser engraving is a precise and intricate process that allows you to create beautiful and personalized designs on glass surfaces. This step-by-step guide provides a comprehensive walkthrough of the engraving process, taking the AlgoLaser Delta diode laser engraver machine for example along with tips for smooth and clean glass engraving.

1. Preparation

Before you begin, ensure you have the right type of glass for laser engraving. Clean the glass surface thoroughly to remove any dirt, dust, or fingerprints. Apply a piece of dark paper to the glass. Secure the glass in the engraving machine, ensuring it's level and stable.

2. Design and Software Setup

Create or select the design you want to engrave on the glass. Use design software that's compatible with your laser engraving machine. Import the design, set the engraving parameters, and adjust the laser power and speed according to your project requirements.

3. Focusing the Laser

The laser beam must be accurately focused on the glass surface. Use the machine's focusing tool to ensure the right focal point. Proper focus is critical for achieving precise results.

4. Engraving

Start the engraving process. The laser will follow the design you've set, removing a thin layer of glass as it goes. The engraving depth can be adjusted based on the project. Monitor the process to ensure the machine is running smoothly.

5. Management and Troubleshooting

During engraving, keep an eye on the machine. If you notice any issues such as smoke or a strong odor, pause the machine and address the problem. Ensure proper ventilation to remove fumes. If the engraving isn't as expected, double-check your settings and the focus of the laser.

6. Rotary Attachment (if applicable)

If you're engraving a cylindrical object like a glass tumbler, use a rotary attachment to rotate the glass evenly. This ensures consistent engraving around the circumference.

7. Post-Processing

Once the engraving is complete, remove the glass from the machine. Clean it gently with a soft cloth to remove any residual dust or debris. You can add finishing touches or colors to enhance the engraving if needed.

8. Safety Precautions

Always follow safety guidelines when working with laser engraving machines. Wear appropriate safety gear, including laser safety goggles. Ensure the workspace is well-ventilated, and never leave the machine unattended during operation.

Tips for a Smooth and Clean Glass Engraving:

· Experiment with different power and speed settings to achieve the desired engraving effect.

· Use air assist to blow away debris during engraving, keeping the surface clean.

· Test your design on a scrap piece of glass before engraving the final product.

· Regularly maintain and clean your laser engraving machine to ensure consistent results.

· Be patient and take your time to achieve the best quality engraving.

Glass laser engraving can be a rewarding and creative process when done correctly. Following these steps and tips, you can create stunning and personalized glass artworks, gifts, or decorative items with precision and finesse.

Popular Glass Laser Engraving Projects and Ideas

Glass laser engraving offers a world of creative possibilities. Here are some popular projects and ideas to spark your inspiration:

1. Personalized Glassware

Engrave names, initials, or special messages on glassware like wine glasses, mugs, and tumblers for unique and personalized gifts.

2. Decorative Glass Panels

Create intricate designs on glass panels for decorative room dividers, cabinet doors, or wall art.

3. Wedding and Anniversary Gifts

Customize glass photo frames, champagne flutes, or decorative plates with the names and dates of the happy couple.

4. Corporate Awards

Craft elegant glass awards and trophies with engraved company logos and achievements to honor employees and partners.

5. Glass Signage

Make a striking impression with laser-engraved glass signage for businesses, restaurants, and offices.

6. Artistic Glass Sculptures

Experiment with three-dimensional glass engraving to craft unique sculptures and art pieces.

7. Architectural Elements

Enhance architectural projects with engraved glass balustrades, windows, and doors.

8. Promotional Items

Laser-engraved glass keychains, USB drives, and other promotional items make for memorable corporate giveaways.

image credit: JovelyCo - Etsy

Conclusion

Glass engraving is a captivating and versatile art form that opens the door to a world of creative possibilities. This process involves using a laser to meticulously etch intricate designs onto glass surfaces. The results are stunning, and the applications are virtually limitless.

With the right equipment and techniques, you can transform plain glass into personalized and decorative pieces. Whether you're interested in creating custom glassware, elegant awards, or intricate art, glass engraving can bring your vision to life with precision and finesse.

So, if you're intrigued by the idea of glass engraving, don't hesitate to dive in and start practicing. This art form offers an exciting journey of exploration, innovation, and self-expression. Let your imagination run wild and embark on a creative adventure with glass engraving.

Free SVG & Gcode Files for Laser Engraving & Cutting can be found here, wich you can import into our laser cutters directly.

- Choosing a selection results in a full page refresh.