How To Laser Engrave Denim with LightBurn

In the vibrant world of fabric design and customization, laser engraving stands out as a cutting-edge technique that transforms ordinary denim into bespoke masterpieces. This method, synonymous with precision, allows for intricate patterns, detailed images, and text to be etched onto denim, offering endless possibilities for personalization and creativity. Central to executing such precision on denim is the use of laser engravers, sophisticated devices that can meticulously remove the top layer of fabric to reveal designs that are both stunning and durable. At the heart of this technological marvel is LightBurn, a powerful software that seamlessly integrates with a wide range of laser engravers, making it accessible for artists, designers, and hobbyists to bring their visions to life.

Free SVG & Gcode Files for Laser Engraving & Cutting can be found here, wich you can import into our laser cutters directly.

The Evolution of Laser Engraving Technology

Laser engraving technology has seen a remarkable evolution from its initial applications to becoming a mainstay in the world of fabric customization. The principle behind laser engraving is straightforward yet profound: a laser beam is precisely focused onto the material's surface, where it vaporizes the fabric in a controlled manner to produce a design. This process can be finely tuned to affect only the surface or to penetrate more deeply, depending on the desired effect.

image credit: DylemmaDesign - Etsy

The Role of the Laser Engraver in Denim Artistry

In the specific context of denim engraving, the choice of laser engraver is pivotal. The most commonly used lasers for this purpose are Diode laser engravers, renowned for their efficiency in interacting with organic materials like cotton—the primary component of denim. The Diode laser engraver operates by emitting a concentrated beam of light that heats up the denim fabric, selectively burning away areas to create contrasting designs without compromising the integrity of the material.

Denim, with its rugged texture and durable weave, presents an ideal canvas for laser engraving. The process not only allows for the creation of intricate designs but also adds a dimension of texture that is tactile and visually appealing. The key to mastering denim laser engraving lies in understanding the laser's power settings, speed, and focus, parameters that dictate the fineness of the engraving and the depth of the design.

image credit: AllThisWood - Etsy

Harnessing the Power of LightBurn Software

Enter LightBurn, the software solution that has transformed how artists and designers approach laser engraving. LightBurn's compatibility with a wide range of laser engravers, including CO2 models, makes it a versatile tool for projects involving denim. Its intuitive interface and robust design tools allow users to create, import, and modify designs before sending them to the laser engraver.

One of LightBurn's strengths is its ability to precisely control the laser's operations, offering users the capability to adjust settings such as power, speed, and the number of passes for each project. This level of control is crucial when working with denim, as variations in fabric density and color can significantly affect the outcome of the engraving.

image credit: AHInspirations - Etsy

Step-by-Step Guide to Laser Engraving Denim with LightBurn

Step 1, power on the machine, and wait for the module stopping at the original point.

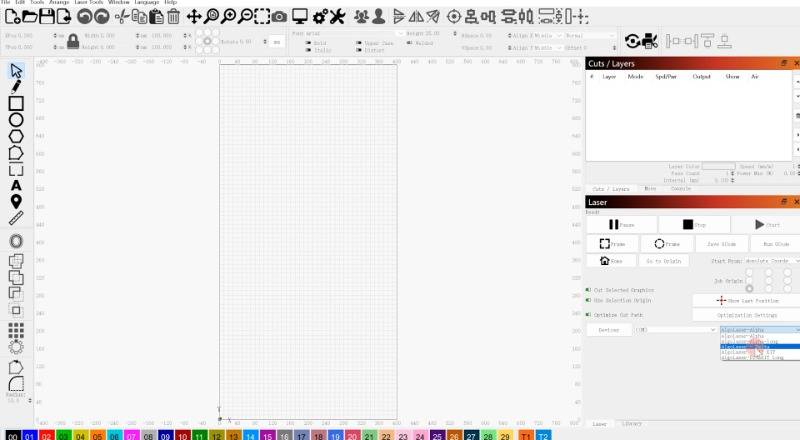

Step 2, open the LightBurn.

Choose the corresponding machine, Wait for the console to display “OK”.

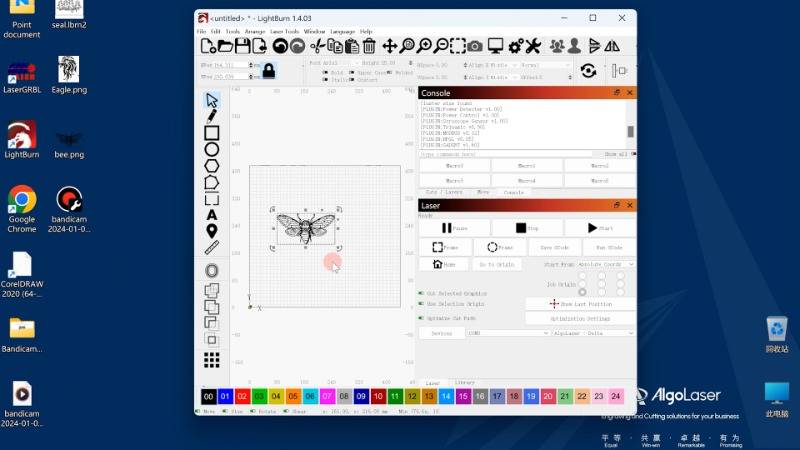

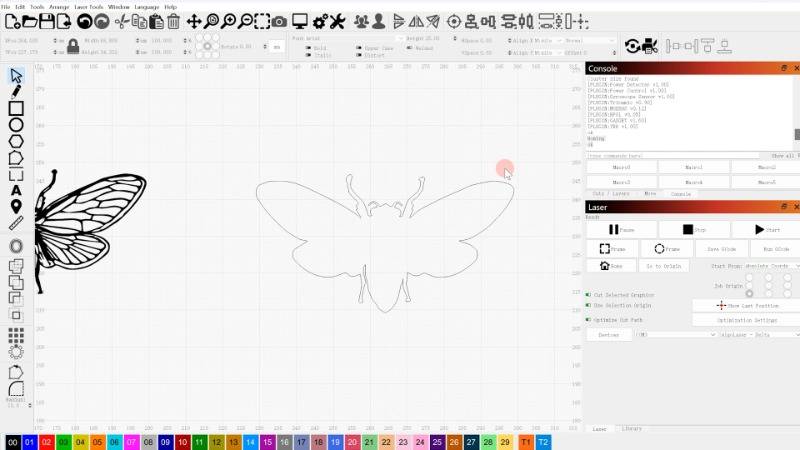

Step 3, drag the prepared pattern into the workspace.

Adjusting the image size.

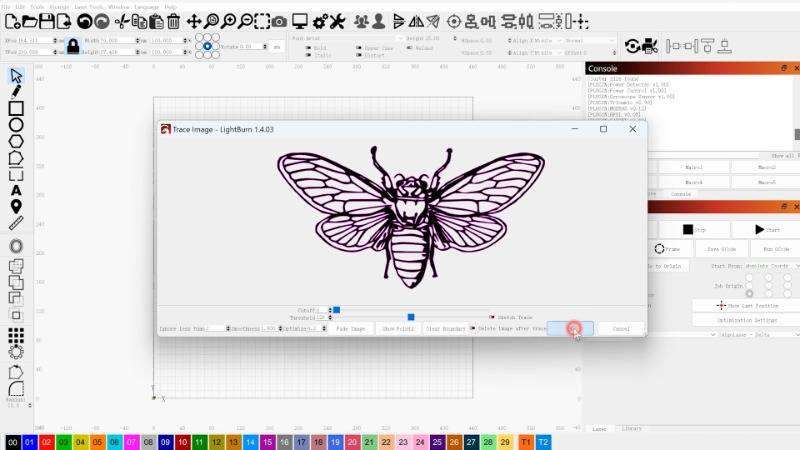

Click “Trace image”,Trace image lines, click”OK “.

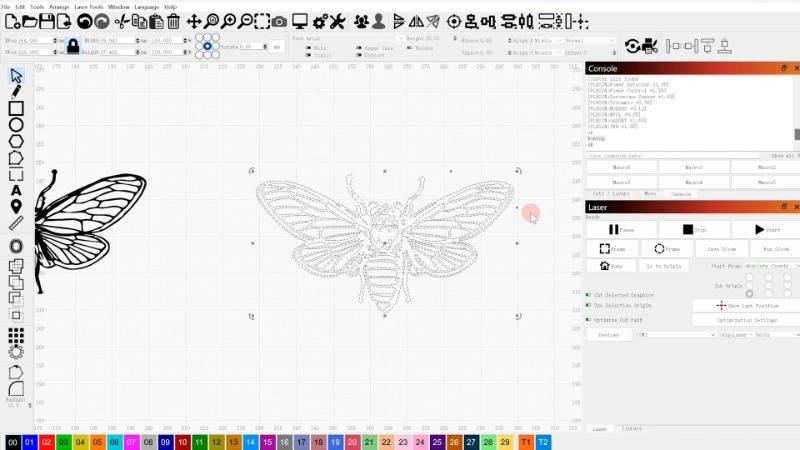

Click “Ungroup”.

Select the internal dotted line and delete.

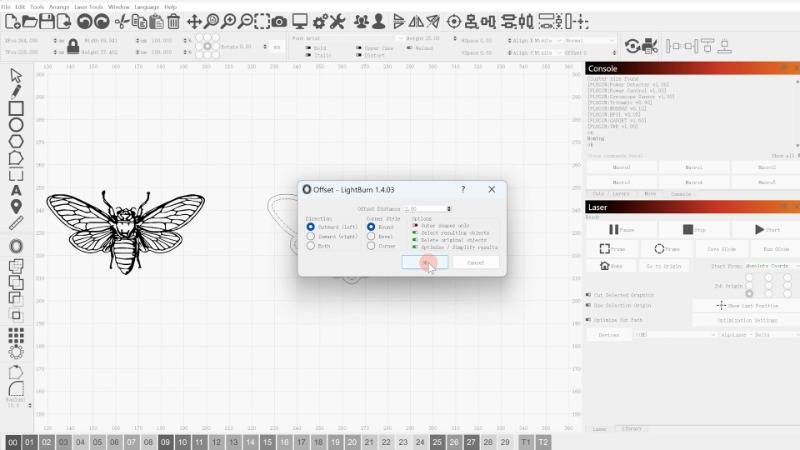

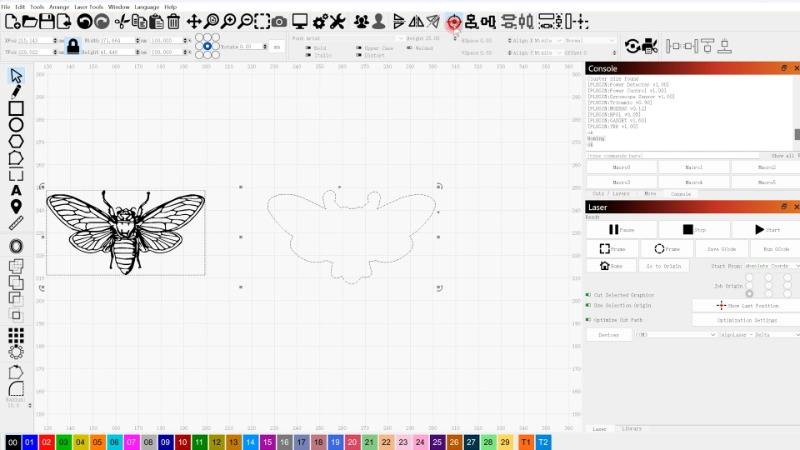

Click "Offset” , set parameters.

Click to center.

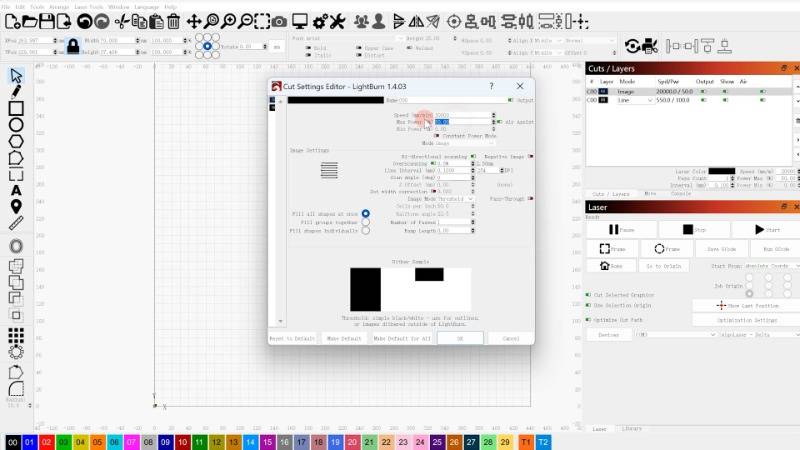

Click on the console to set the engraving parameters.

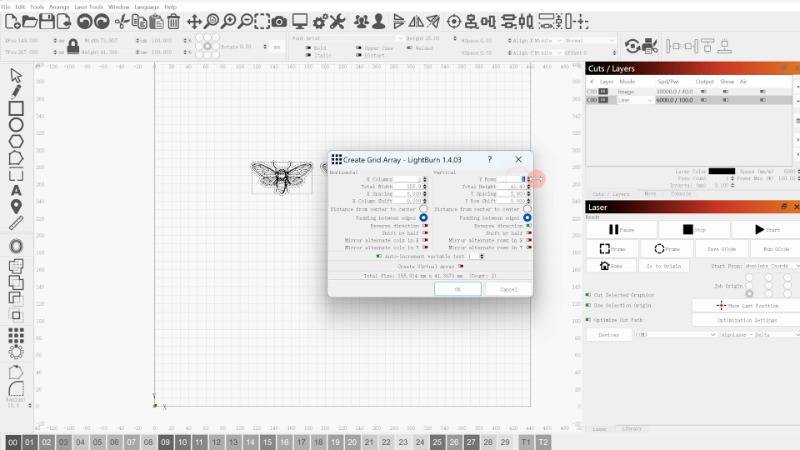

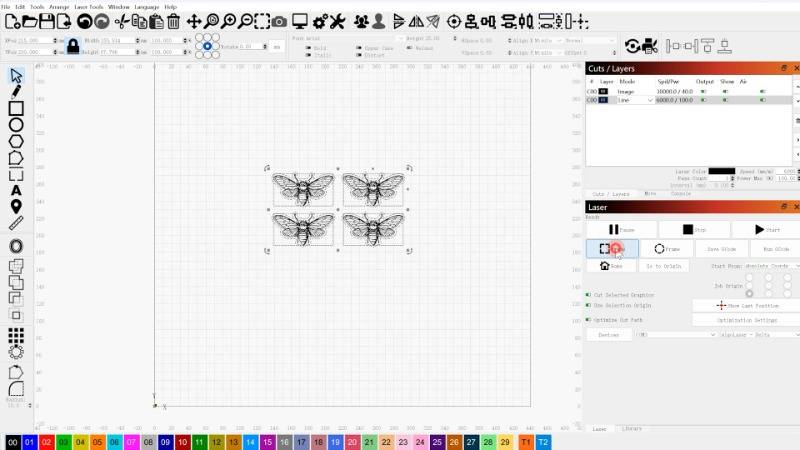

Click the icon for batch operation, you can set the rows and columns according to your own needs.

Step 4, click “Frame” button to determine the processing area.

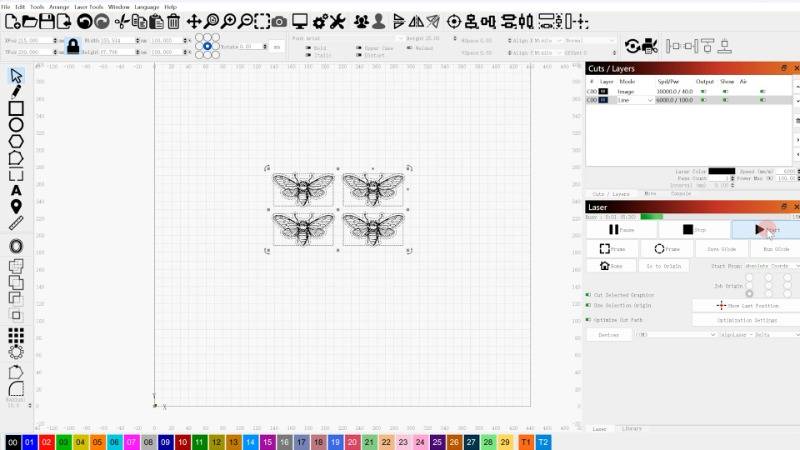

Step 5, click “Start”.

The 10 Best Laser Engraved Fabric Pieces

1. The Renaissance of Denim

Highlight a piece where classic denim is reborn through laser engraving. Describe how the laser engraver, guided by LightBurn's precise control, intricately carves detailed patterns or scenes onto a denim jacket or jeans, infusing them with a new identity and turning everyday apparel into a statement piece.

2. Eco-Friendly Cotton Tote Bags

Focus on tote bags that have been transformed with laser-engraved logos, patterns, or artwork. Emphasize the sustainable aspect of using laser engraving for customization, reducing waste by creating durable and timeless pieces.

image credit: BridesmaidsHouse - Etsy

3. Elegant Laser-Engraved Silk Scarves

Silk's delicate nature makes it a challenging but rewarding fabric for laser engraving. Showcase a piece where LightBurn has been used to create soft, ethereal designs on silk scarves, combining elegance with technological precision.

4. Personalized Polyester Athletic Wear

Athletic wear requires a resilient design that can withstand movement and washing. Present a laser-engraved polyester piece that not only demonstrates durability but also features vibrant, motivational designs that inspire both the wearer and onlookers.

image credit: RedBoxCraft - Etsy

5. Innovative Leather Patches on Wool Sweaters

Leather and wool blend tradition with modernity. Highlight a wool sweater enhanced with laser-engraved leather patches, detailing the process of engraving both materials and attaching them to create a piece that bridges rustic and contemporary styles.

6. Avant-Garde Tyvek Fashion Pieces

Tyvek, a synthetic material known for its durability and resistance to wear, offers a unique canvas for laser engraving. Showcase avant-garde fashion pieces made from Tyvek, engraved with futuristic designs or text, reflecting on how this material pushes the boundaries of traditional fashion.

image credit: DylemmaDesign - Etsy

7. Customized Canvas Sneakers

Turn to the world of footwear, where canvas sneakers serve as a popular medium for laser engraving. Discuss how artists use LightBurn to apply personalized artwork or patterns to sneakers, transforming them into one-of-a-kind pieces of wearable art.

8. Bespoke Wedding Gowns

Wedding gowns symbolize beauty and unity. Share a story of a bespoke wedding gown enhanced with laser-engraved designs, focusing on the romantic and personalized touches that make the dress uniquely significant to the bride.

image credit: ThePaisleyBox - Etsy

9. Decorative Home Textiles

Beyond apparel, laser engraving breathes life into home decor. Highlight decorative home textiles, such as laser-engraved curtains or tablecloths, which add a personalized touch to living spaces with intricate patterns or meaningful quotes.

10. Revolutionary Upcycled Pieces

Conclude with a piece that exemplifies the potential of laser engraving in the sustainable fashion movement. Feature an upcycled fabric item, perhaps previously discarded, now beautifully renewed with laser-engraved designs, embodying the ethos of innovation and environmental consciousness.

image credit: AllThisWood - Etsy

More Than 6 FAQs About Laser Engraving Fabric

1. Can all types of fabric be laser engraved?

Not all fabrics respond equally to laser engraving due to differences in their composition and structure. Natural fibers like cotton, linen, and silk usually yield the best results because they can be precisely cut and engraved without melting. Synthetic fabrics, such as polyester, can also be engraved, but they require lower power settings to prevent burning or melting. It's important to test a small piece of fabric first to determine the optimal laser settings.

2. What's the difference between laser engraving and laser cutting fabric?

Laser engraving and laser cutting are both processes performed by a laser engraver but with different outcomes. Laser engraving involves removing the top layer of the fabric to create a design, producing a textured, visually distinct area. Laser cutting, on the other hand, goes through the fabric entirely, cutting it into shapes or designs. The main difference lies in the laser's power and speed settings; engraving uses lower power to mark the fabric, while cutting requires higher power to penetrate through the material.

3. How do I prevent the fabric from burning during laser engraving?

To prevent fabric from burning, start by using the lowest power setting that still achieves the desired engraving effect. The type of fabric and the laser engraver's specifications will dictate these settings. Always conduct a test run on a scrap piece of fabric to fine-tune the power and speed. Additionally, keeping the laser lens clean and properly focused can help achieve precise results without unnecessary heat buildup.

4. Is it safe to laser engrave any fabric?

While many fabrics are safe to laser engrave, it's crucial to avoid materials that can release harmful fumes when burned, such as PVC-coated materials. Always work in a well-ventilated area and use a laser engraver equipped with an exhaust system to remove fumes from the work area. If unsure about a fabric's safety, consult the material's safety data sheet or contact the manufacturer.

5. How do I choose designs for laser engraving on fabric?

Choose designs that complement the fabric's texture and purpose. For intricate designs, opt for fabrics with a tight weave for clearer details. Consider the end use of the fabric; for wearable items, simpler designs might be more durable and resistant to wear. Utilize software like LightBurn to create or modify designs, taking advantage of its features to adjust the design's size, complexity, and engraving parameters to suit the fabric.

6. Can laser engraved designs on fabric be washed?

Yes, laser-engraved designs on fabric are generally washable, but the fabric's care instructions should always be followed to avoid damage. It's advisable to use gentle washing cycles and avoid bleach, which could affect the contrast and clarity of the engraving. For the best results, turn the fabric inside out before washing and use cold water.

7. How does LightBurn software enhance the laser engraving process on fabric?

LightBurn software provides a user-friendly interface and powerful tools specifically designed for laser engraving, making it easier to create, edit, and import designs. It supports a wide range of laser engravers and offers precise control over engraving parameters, such as speed, power, and number of passes, which can be adjusted to suit different types of fabric. LightBurn's simulation feature allows users to preview the engraving process, helping to optimize settings and reduce material waste.

image credit: FringeCrafts - Etsy

Conclusion

Reflect on the transformative power of laser engraving in the fashion industry and the role of hobbyists and professionals in pushing the boundaries of what's possible with denim. Encourage readers to view laser engraving not just as a method of customization, but as an art form that blends technology with personal expression.

Free SVG & Gcode Files for Laser Engraving & Cutting can be found here, wich you can import into our laser cutters directly.

- Choosing a selection results in a full page refresh.