Diode Laser vs. Traditional Engraving on Fabrics: Precision Meets Craft

Diode laser vs. traditional engraving on fabrics highlights the evolution of textile customization and modern fabric engraving technology. Fabric has always been a favorite medium for personalization, from embroidery and textile printing to hand-engraving methods that give garments and textiles their unique character. But in recent years, laser engraving for fabrics has emerged as a modern alternative, offering unmatched precision, speed, and versatility in fabric customization and apparel design. When it comes to textiles, the comparison between diode laser engraving machines and traditional fabric engraving techniques highlights just how far laser technology has brought this art.

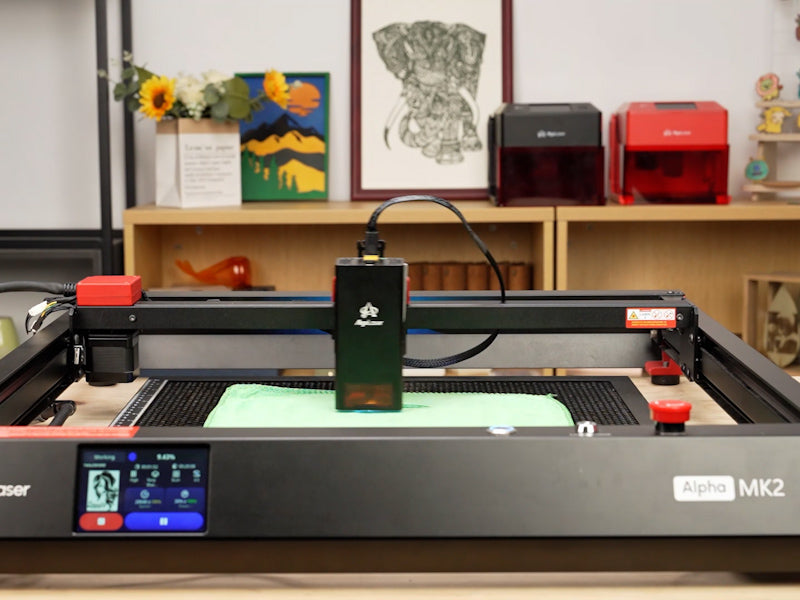

Understanding Fabric Engraving with Lasers

Laser engraving on fabric works by directing a concentrated beam of light onto the surface, vaporizing or etching the fibers to create permanent marks and detailed patterns. Unlike mechanical engraving tools, which apply physical pressure, laser engraving is a non-contact process. This means there is no risk of tearing, stretching, or distorting delicate textiles. Even the most sensitive materials—cotton, silk, satin, or velvet—can be engraved with surprising accuracy and detail.

Diode lasers, in particular, are popular for fabric laser engraving because of their affordability and ability to work at low power settings. Their fine laser spot size makes them ideal for intricate patterns, custom logos, and decorative engraving on natural fibers and lightweight textiles. On the other hand, more powerful laser systems, such as CO₂ lasers, are often used for larger-scale applications or when cutting and engraving synthetic fabrics that require higher wattage and deeper material penetration.

Traditional Fabric Engraving in Perspective

Traditional methods of fabric engraving rely heavily on manual craftsmanship and mechanical tools. Techniques might involve rotary engraving tools, heated branding, or hand-cut patterns for textile decoration. While these methods can achieve beautiful, tactile results, they are less precise and far more time-consuming than modern laser engraving solutions.

The outcome depends heavily on the artisan’s skill, and results may vary from piece to piece. For thicker fabrics like denim and canvas, traditional engraving may work reasonably well. However, for finer materials such as silk, polyester, or performance textiles, the risk of fraying, warping, and material damage is significant. Modern laser engraving for textiles solves these challenges by delivering clean, precise marks without physical contact.

Comparison: Diode Laser Engraving vs. Traditional Methods

| Feature | Diode Laser Engraving | Traditional Engraving |

|---|---|---|

| Precision & Detail | Extremely fine detail, capable of replicating small fonts and complex designs consistently | Depends on artisan skill; difficult to achieve fine or repeatable patterns |

| Speed & Efficiency | Fast, automated, and ideal for batch processing | Slow, labor-intensive, and not suited for large production runs |

| Material Compatibility | Works best with natural fibers like cotton, linen, and denim; adjustable for some synthetics | Possible on most fabrics but risks damaging delicate materials like silk or polyester |

| Consistency | Every piece looks the same thanks to digital control | Results vary depending on tool sharpness and user technique |

| Durability | Permanent marks resistant to fading and washing; seals edges on synthetics | Marks may wear down or fray over time, especially with frequent laundering |

| Setup & Maintenance | Minimal upkeep; no tool wear; simple to operate | Tools dull and require frequent maintenance; setup depends on artisan’s expertise |

| Cost & Accessibility | Entry-level friendly; affordable for hobbyists and small businesses | Low entry cost but high time investment; less practical for scaling |

| Aesthetic Appeal | Clean, modern finish ideal for branding and personalization | Handcrafted texture with a unique artisanal feel |

| Safety | Non-contact process reduces risk of fabric tearing and user injury | Requires careful handling of sharp or heated tools; higher risk of material damage |

Key Advantages of Diode Laser Engraving Over Traditional Methods

1. Precision and Detail

Diode lasers excel at producing sharp, clean lines and high-resolution engraving. They can engrave small fonts, complex patterns, and photographic designs that would be nearly impossible to achieve by hand or with mechanical tools. This precision makes laser engraving ideal for custom apparel, branding, and personalized textile products.

2. Speed and Efficiency

What might take hours with manual engraving tools can be accomplished in minutes with a laser engraving machine. Because the process is automated, engraving multiple pieces in a production batch is both practical and consistent. This efficiency is especially valuable for businesses offering customized fabric products and personalized textile branding.

3. Material Compatibility

Natural fabrics like cotton, linen, and denim respond especially well to diode laser engraving. The laser gently etches the fibers without damaging the overall integrity of the material. Synthetic fabrics, while more challenging, can also be engraved with the right laser parameters, often producing sealed edges that prevent fraying and enhance durability.

Laser engraving for textiles enables creative applications in fashion design, promotional products, and custom home décor. From engraved logos on apparel to decorative patterns on fabric accessories, the possibilities are extensive.

4. Consistency

Every piece engraved with a diode laser will look the same, ensuring uniform quality across production batches. Traditional engraving methods, by contrast, may yield variations in depth, line thickness, and alignment due to manual execution. Consistency is essential for professional-grade textile customization and branding.

5. Low Maintenance

Diode lasers are simple to maintain and operate. They don’t require water cooling systems or constant adjustments, and the wear-and-tear on the equipment is minimal compared to mechanical engraving tools. This reduces operational costs and makes laser engraving accessible for both hobbyists and professional makers.

Safety and Setup

For laser engraving on fabric, preparation plays an important role in achieving optimal results. The fabric should be smooth, wrinkle-free, and securely fixed in place to avoid distortion during engraving. Pre-washing textiles can also prevent shrinking or distortion after processing, ensuring long-lasting engraving quality.

Unlike traditional engraving tools, lasers don’t rely on direct contact, reducing the risk of accidental tears or injuries from slips. The process is clean, with minimal dust or debris, and requires only occasional surface cleaning after engraving. Proper ventilation is recommended when engraving synthetic fabrics to ensure a safe working environment.

Aesthetic and Durability

Laser-engraved fabrics are not only precise but also durable. The marks are permanent, resistant to fading, and able to withstand regular washing, especially on natural fibers. On synthetic fabrics, laser engraving can even enhance durability by melting the edges and preventing unraveling, creating sealed and polished designs.

Traditional methods, while capable of producing beautiful textured effects, may not always offer the same longevity. Engraved marks might wear down faster, particularly with repeated handling or laundering. Laser engraving for apparel and textiles delivers a balance of aesthetics and durability.

Choosing Between Diode Laser and Traditional Engraving

The choice between diode laser engraving and traditional engraving methods often comes down to purpose and application.

· For artistic, one-of-a-kind projects, traditional engraving has its place. The human touch can create depth and personality that machines can’t replicate.

· For detailed, repeatable, and efficient results, a diode laser engraver is the clear winner. It ensures precision, speed, and consistency while remaining accessible in terms of cost and maintenance.

Modern fabric engraving technology enables creators to explore new possibilities in textile design and customization, bridging the gap between traditional craftsmanship and digital innovation.

Final Thoughts

Fabric engraving has evolved from a purely manual craft into a blend of artistry and technology. Diode laser engraving machine makes it possible to create intricate designs with unmatched accuracy, opening new possibilities for personalization, branding, and fashion innovation. While traditional methods retain their charm and unique artistry, the speed, precision, and reliability of modern laser engraving for fabrics are transforming the way textiles are customized today.

In the end, both methods have their place—one grounded in timeless craftsmanship, the other driven by technological progress. Together, they tell the story of how fabric engraving continues to evolve in a world where creativity meets innovation and laser technology enhances artistic expression.

- Choosing a selection results in a full page refresh.