Diode Laser Engraving vs. Traditional Metal Engraving: Which Should You Choose

From intricate jewelry designs to serial numbers on machinery, metal engraving has been a cornerstone of craftsmanship and manufacturing for centuries. Today, the craft spans everything from the delicate artistry of hand engraving to the high-tech precision of modern laser engravers.

One of the most talked-about tools in recent years is the diode laser engraver—a compact, affordable alternative to industrial-grade equipment. But can it really compete with traditional engraving methods? In this blog post, we'll break down the strengths, weaknesses, and best uses of each approach, so you can decide which is right for your needs.

1. Understanding the Main Metal Engraving Methods

Before we compare diode lasers to other tools, let's get familiar with the most common methods for metal engraving.

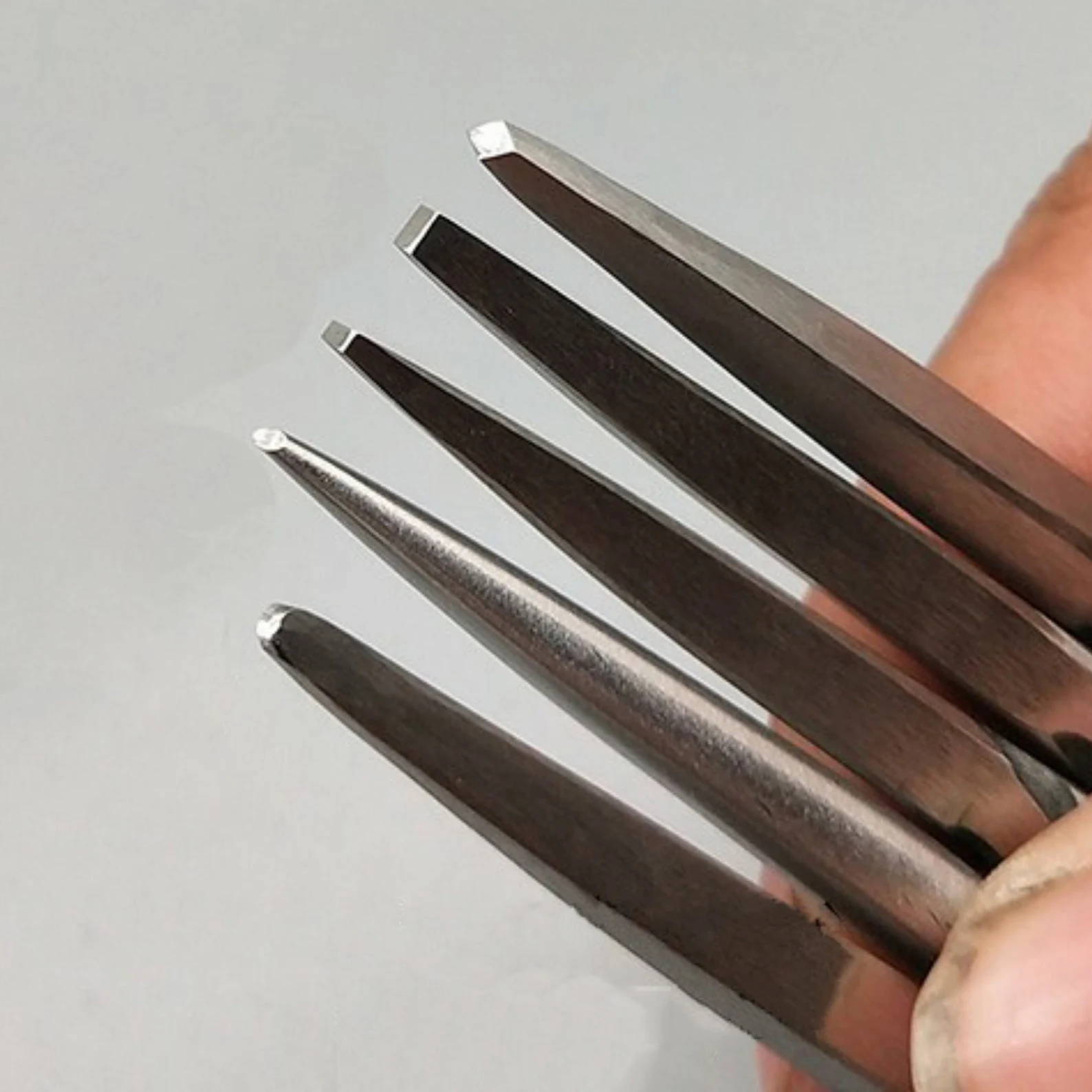

Hand Engraving

This time-honored technique involves using a sharp tool—often called a burin—to carve designs into metal. The engraver controls every movement, creating deep, expressive cuts.

· Best for: Fine jewelry, custom artwork, heirloom pieces.

· Strengths: Unmatched artistic control, deep and permanent marks, timeless beauty.

· Weaknesses: Extremely slow, physically demanding, requires years of practice.

Pantographic or Mechanical Engraving

This method uses a mechanical arm or CNC machine to replicate a design from a template onto metal.

· Best for: Nameplates, signs, serial numbers, awards.

· Strengths: Consistent results, good for batch work, relatively fast.

· Weaknesses: Limited flexibility for unique designs, less detail than hand engraving or lasers.

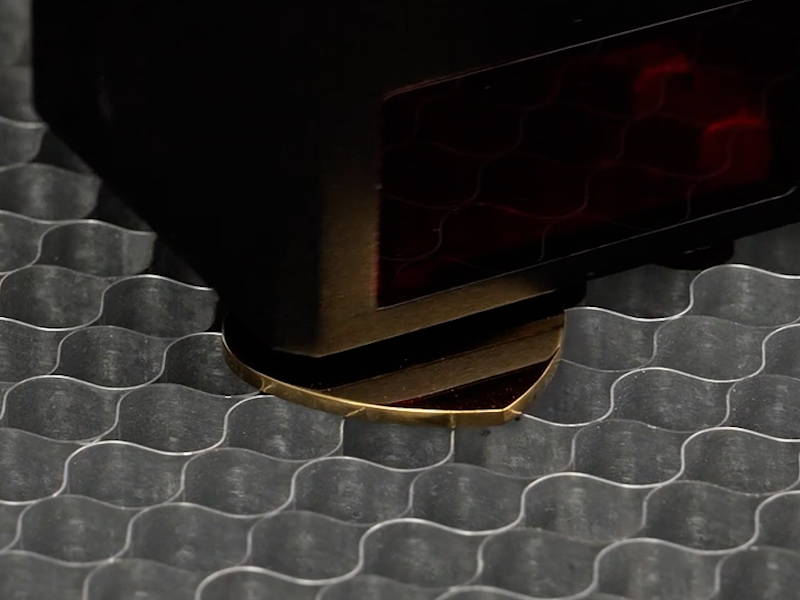

Laser Engraving

Instead of cutting with a physical tool, laser engraving uses focused light to vaporize the metal surface. The laser type determines how well it works on metal:

· Fiber Lasers: Ideal for deep engraving on bare metals, especially stainless steel, titanium, and aluminum.

· CO₂ Lasers: Not directly effective on bare metal but work with coatings.

· Diode Lasers: Affordable and versatile, especially with coated or treated metals.

2. The Rise of the Diode Laser Engraver

Diode lasers are compact machines that use a semiconductor to produce a focused beam of light. While they generally have lower power output than fiber lasers, they're extremely popular among hobbyists, small business owners, and creative professionals.

Advantages of Diode Laser Engraving on Metal

· Cost-Effective Entry Point – A good diode laser engraver can cost a fraction of a fiber laser, making it ideal for beginners or those with small workshops.

· Compact and Portable – Easy to store and move, unlike large industrial units.

· Multi-Material Versatility – Engraves on wood, leather, acrylic, and coated metals, all with one machine.

· Beginner-Friendly – Simple software and safety features make it accessible.

Limitations of Diode Lasers on Metal

· Surface-Level Marking Only on Bare Metal – Without a coating, results are light and temporary.

· Slower Speeds – Less powerful than fiber lasers, so projects can take longer.

· Reliant on Pre-Treatments – For dark, permanent marks, most users apply coatings like Cermark or even creative alternatives like mustard.

3. How Diode Lasers Engrave Metal

When engraving bare metals, the biggest challenge is that they reflect light and dissipate heat quickly, making it hard for a low-power diode to etch the surface. This is why coatings are often used—they absorb the laser's energy, allowing for a dark, permanent bond.

Popular coating methods include:

· Commercial sprays (Cermark, Brilliance, Thermark)

· DIY coatings (acrylic paint, black tempera, mustard)

· Anodized aluminum – already has a coating that engraves beautifully.

With these treatments, diode lasers can create durable markings for jewelry, tools, promotional items, and more.

4. Traditional Engraving Strengths & Weaknesses

Hand Engraving:

· Pros: Permanent, deeply cut lines, adds artistic value.

· Cons: Time-consuming, expensive, requires high skill.

Pantographic/Mechanical Engraving:

· Pros: Efficient for batches, repeatable designs.

· Cons: Less artistry, limited to fixed templates.

5. Head-to-Head Comparison

| Method | Advantages | Disadvantages |

|---|---|---|

| Diode Laser (with coating) | Affordable, compact, versatile, beginner-friendly | Needs coating, slower, limited on bare metals |

| Fiber Laser | Deep, permanent, precise engraving on bare metals | Expensive, larger, more complex |

| Hand Engraving | Artistic, deep, unique | Slow, costly, skill-intensive |

| Pantographic Engraving | Consistent, good for volume | Limited flexibility, less detail |

6. Why Many Makers Choose Diode Lasers

In online communities like Reddit's r/Laserengraving and r/lasercutting, users often highlight that diode lasers are perfect for side businesses and creative projects. They can personalize metal tumblers, create dog tags, and mark tools without the large investment of a fiber laser.

Example feedback from makers:

"A diode laser won't engrave bare stainless steel deeply, but with Cermark spray, the results can be sharp and long-lasting."

"Fiber lasers are amazing, but if you're on a budget, a diode laser will get you creating today."

7. Choosing the Right Engraving Method

When deciding between a diode laser engraver and traditional metal engraving:

· Choose a Diode Laser if: You need a versatile, affordable tool for coated metals and other materials like leather or wood.

· Choose a Fiber Laser if: You require deep, permanent engraving on bare metal at high speed.

· Choose Traditional Engraving if: You want handcrafted artistry or have heritage-style projects.

· Choose Pantographic if: You need consistent mass production with simple designs.

8. Final Thoughts

Both diode laser metal engraving and traditional metal engraving have their place. If you value artistry and craftsmanship, traditional engraving is unmatched. If you want an affordable, all-around creative tool, a diode laser engraver offers an incredible starting point—especially for small businesses, hobbyists, and anyone working with multiple materials.

The right engraving method depends on your goals, budget, and desired finish. But whichever you choose, you'll be part of a craft that transforms plain metal into something meaningful, lasting, and beautiful.

![[Discontinued] AlgoLaser Alpha 22W Laser Engraver (Recommended: Alpha MK2 20W)](http://algolaser.com/cdn/shop/files/ALPHA_22W_1a87454a-b664-43bf-85c7-63606755bbf8_533x.jpg?v=1734401523)