How Delta Engraves on Denim with LaserGRBL

The marriage of technology and craftsmanship has led to remarkable innovations in textile design. Fabrics like denim can be engraved and cut using diode laser engraving machines. With the help of sophisticated software like LaserGRBL, designers can create intricate designs with precision. Using Delta laser engraving machines, we explore techniques, applications, and LaserGRBL's essential role in denim engraving.

Types of Laser Cutting on Fabric Materials

Laser cutting technology offers a range of methods tailored to different fabric materials, each with its unique advantages and applications.

CO2 Laser Engraving and Cutting

Description: CO2 lasers are widely used for both engraving and cutting fabric materials. These lasers emit a beam of infrared light, which is absorbed by the fabric, causing it to vaporize and create precise cuts or etchings.

Suitable Fabrics: CO2 lasers are suitable for engraving and cutting a wide range of fabrics, including cotton, polyester, silk, wool, and synthetic blends.

Advantages: CO2 laser technology offers high precision, versatility, and the ability to create intricate designs with minimal fraying or distortion. It is suitable for both thin and thick fabrics.

Applications: CO2 laser engraving and cutting find applications in garment manufacturing, upholstery, embroidery, quilting, and fashion design.

Diode Laser Engraving and Cutting

Description: Diode lasers are compact and affordable laser machines ideal for engraving and cutting natural fibers such as cotton and denim. They emit a focused beam of light that melts and vaporizes the material, creating clean cuts or etchings.

Suitable Fabrics: Diode lasers are well-suited for engraving and cutting natural fabrics like cotton, denim, linen, and wool. They can also handle some synthetic fabrics, although their effectiveness may vary.

Advantages: Diode laser technology offers high precision, affordability, and the ability to work with thicker fabrics. It is suitable for small-scale production and prototyping.

Applications: Diode laser engraving and cutting are commonly used in fashion design, upholstery, home textiles, and crafts.

Fiber Laser Engraving and Cutting

Description: Fiber lasers use a solid-state laser source to generate a concentrated beam of light that is capable of engraving and cutting through thin fabric materials with high speed and precision.

Suitable Fabrics: Fiber lasers are best suited for engraving and cutting thin fabrics such as silk, chiffon, and organza. They may not be suitable for thicker fabrics or materials with high moisture content.

Advantages: Fiber laser technology offers high speed, precision, and the ability to engrave and cut reflective materials without the need for additional coatings. It is suitable for high-volume production and industrial applications.

Applications: Fiber laser engraving and cutting are used in garment manufacturing, automotive upholstery, technical textiles, and signage.

Waterjet Cutting (Bonus)

Description: While not a laser technology, waterjet cutting is worth mentioning for its ability to cut a wide range of fabric materials. Waterjet cutting uses a high-pressure stream of water mixed with abrasive particles to cut through the fabric.

Suitable Fabrics: Waterjet cutting can be used to cut various fabrics, including thick materials like leather and foam. It is particularly effective for heat-sensitive fabrics or materials with a high moisture content.

Advantages: Waterjet cutting offers high precision, minimal heat transfer to the material, and the ability to cut through thick and layered materials with ease. It is suitable for custom designs and intricate patterns.

Applications: Waterjet cutting is used in fashion design, upholstery, automotive interiors, and aerospace for cutting fabric materials.

The Role of LaserGRBL in Laser Engrave and Cut on Fabric

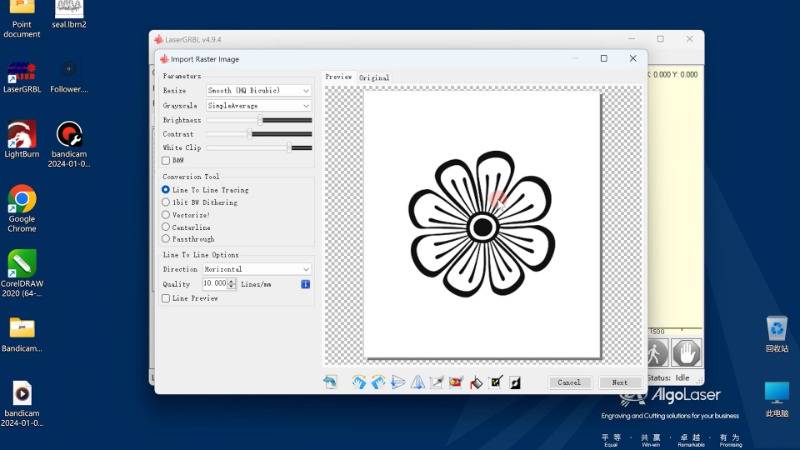

LaserGRBL is a powerful software tool designed to facilitate laser engraving and cutting processes with ease and precision. Its intuitive interface allows users to import designs, adjust settings such as engraving depth and cutting speed, and simulate the process in real-time.

Key features of LaserGRBL include:

Design Import

LaserGRBL supports various file formats, enabling designers to import their designs seamlessly.

Customization Options: Users can adjust parameters such as laser power, speed, and resolution to achieve the desired engraving or cutting results.

Real-Time Preview

The software provides a real-time preview of the engraving or cutting process, allowing users to fine-tune settings before execution.

Compatibility

LaserGRBL is compatible with a wide range of laser engraving machines, including Delta diode laser engraver, ensuring versatility and accessibility for designers.

How To Laser Engrave and Cut on Denim with LaserGRBL by AlgoLaser Delta

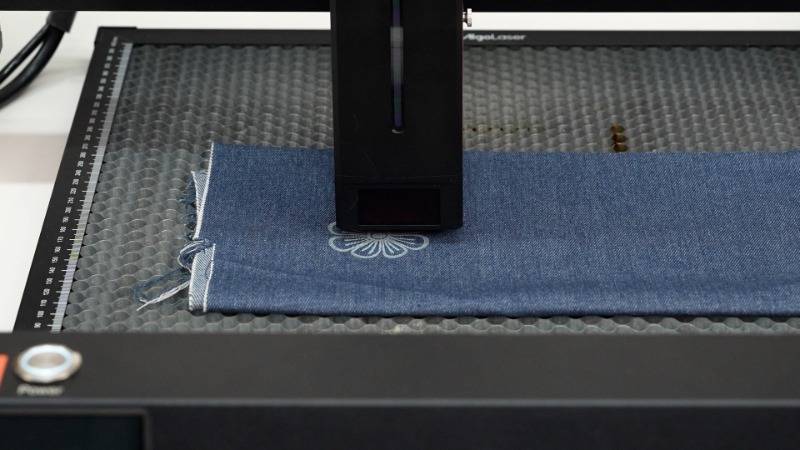

AlgoLaser Delta is a state-of-the-art diode laser engraving machine specifically optimized for fabric engraving and cutting, including denim. When combined with LaserGRBL, it offers a seamless and efficient workflow for denim engraving projects.

Here's a step-by-step guide to laser engraving and cutting on denim with AlgoLaser Delta and LaserGRBL:

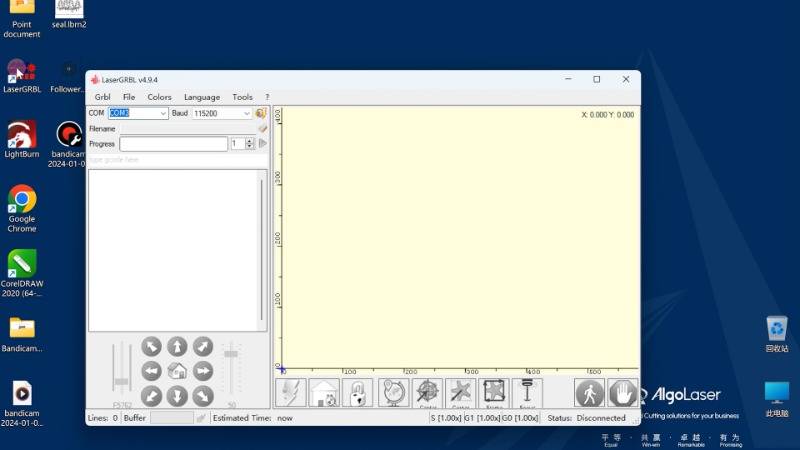

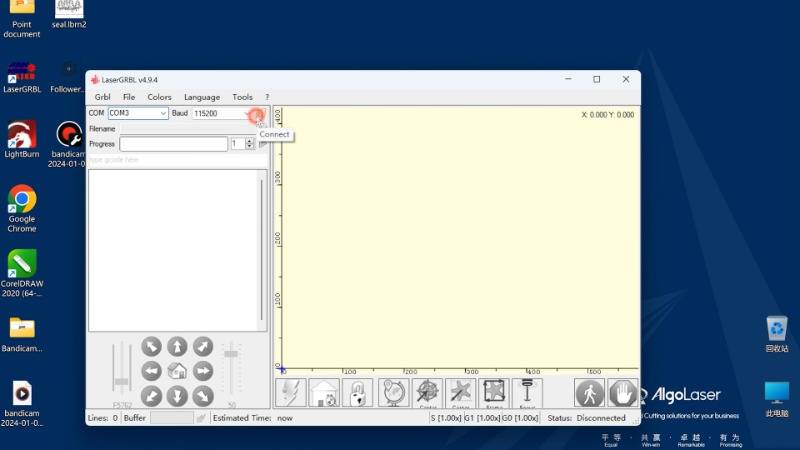

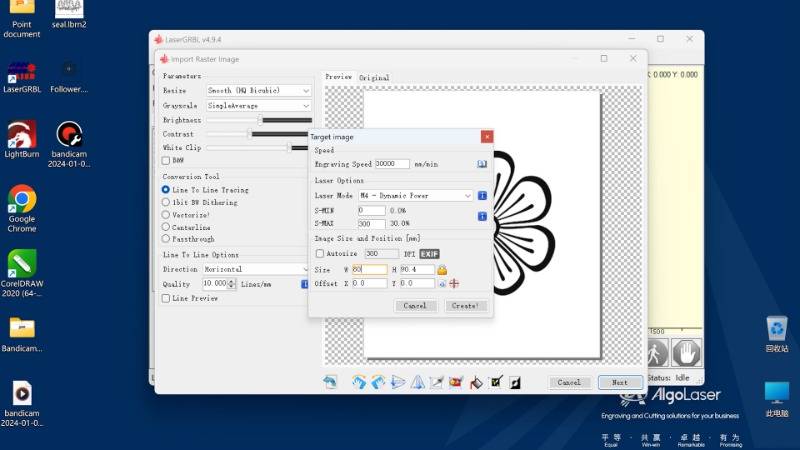

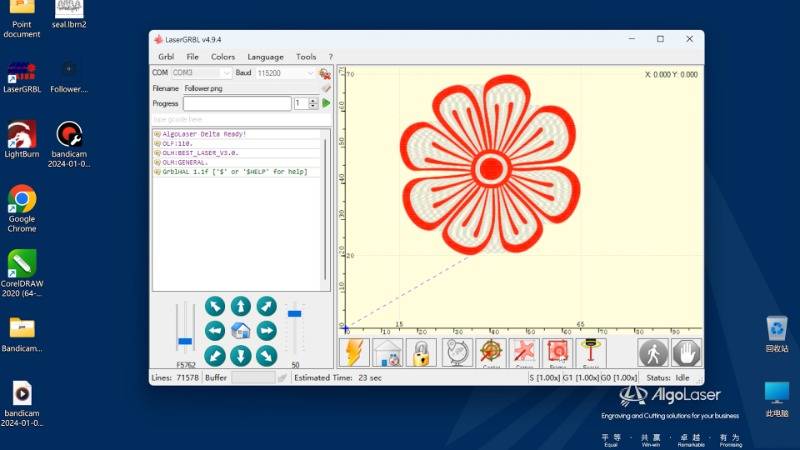

Step 1, open the LaserRGBL, click on the connection icon. Drag the prepared pattern into the workspace.

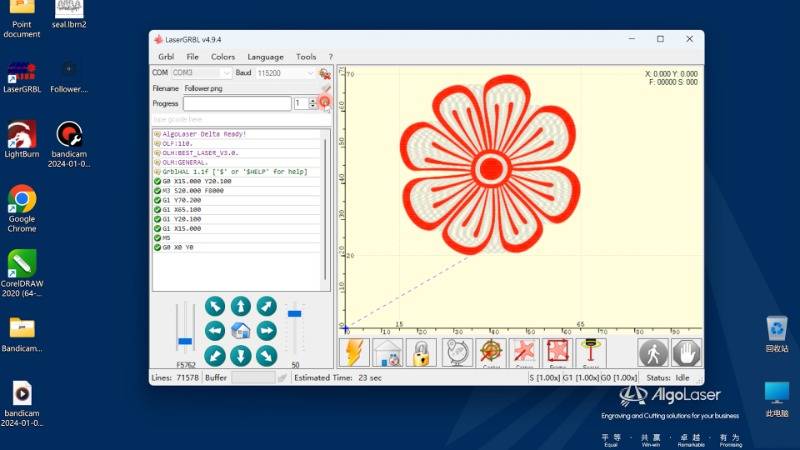

Step 2, set the engraving parameters as required. Wait for the image processing to complete.

Step 3, click "Frame" button to determine the processing area.

Step 4, click "Start" .

FAQs About Laser Engraves on Denim

Can laser engraving weaken the fabric structure of denim?

Laser engraving on denim typically does not weaken the fabric structure, as the heat from the laser is controlled and localized, minimizing damage to surrounding fibers.

Is laser engraving on denim eco-friendly?

Compared to traditional methods like chemical bleaching or manual distressing, laser engraving on denim is more environmentally friendly, as it reduces water consumption and eliminates the need for harsh chemicals.

Can laser engraving achieve intricate designs on denim?

Yes, laser engraving can achieve highly intricate designs on denim, from intricate patterns to detailed portraits, with precision and clarity.

Does laser engraving on denim produce harmful fumes?

Laser engraving on denim may produce minimal fumes, but proper ventilation systems in the engraving workspace can mitigate any potential health risks.

How durable is laser engraving on denim?

Laser engraving on denim creates permanent designs that are highly durable and resistant to fading or peeling, ensuring longevity and quality.

Can laser engraving on denim be washed?

Yes, laser-engraved denim can be washed like regular denim, with the engraved designs retaining their integrity even after multiple washes.

By addressing these frequently asked questions, designers can gain a better understanding of the benefits and considerations of laser engraving on denim.

Conclusion

In conclusion, the integration of Delta laser engraving technology with LaserGRBL software has revolutionized the art of denim engraving and cutting. By harnessing the precision and versatility of diode laser engraving machines, designers can create intricate designs with unparalleled detail and clarity. With the support of LaserGRBL, the process becomes streamlined and efficient, allowing for greater experimentation and creativity. As the fashion industry continues to evolve, laser engraving remains a cornerstone of innovation and sustainability, offering endless possibilities for expression and design. Embrace the power of Delta laser engraving with LaserGRBL, and elevate your denim artistry to new heights.

- Choosing a selection results in a full page refresh.