How Delta Cut on Plywood with LightBurn

Plywood is an incredibly versatile material that offers a vast array of application possibilities. Due to its adaptability and advancements in technology, laser cutting and engraving techniques have become widely used. Our focus will be on combining plywood crafting with the precision of diode laser engraving machines, using AlgoLaser Delta alongside LightBurn software. Let's discover how Delta Cut can revolutionize your woodworking projects by exploring its intricacies.

Types of Laser Cutting on Plywood Materials

Laser cutting techniques on plywood can be broadly classified into two main categories: vector cutting and raster engraving. Vector cutting involves the precise cutting of plywood along predefined paths, resulting in clean edges and intricate shapes. This method is ideal for creating intricate designs, prototypes, and functional components. On the other hand, raster engraving entails etching designs onto the surface of the plywood, adding texture and detail. It's commonly used for decorative purposes, signage, and branding applications.

The Role of LightBurn in Laser Cut on Plywood

LightBurn emerges as a pivotal tool in the realm of laser engraving and cutting on plywood. Its user-friendly interface and robust features streamline the design process, allowing users to import, customize, and optimize their projects with ease. With LightBurn, craftsmen can effortlessly adjust cutting parameters such as power, speed, and focal depth to achieve precise results. Additionally, its compatibility with various file formats and intuitive layout make it a preferred choice among woodworking enthusiasts and professionals alike.

How To Laser Engrave and Cut on Plywood with LightBurn by AlgoLaser Delta

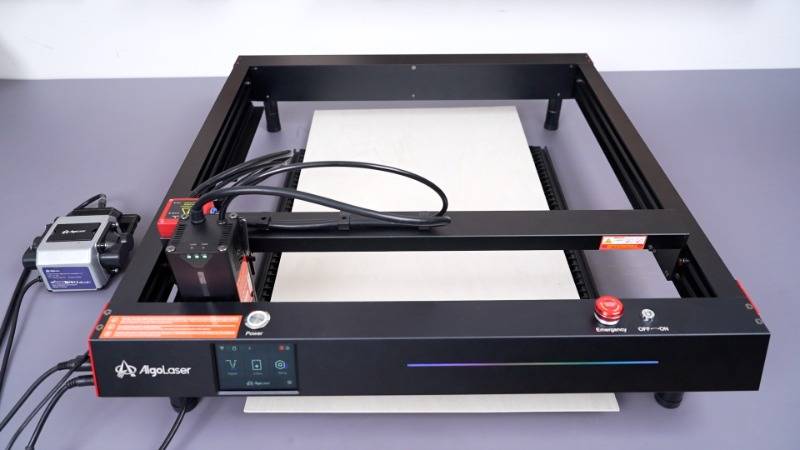

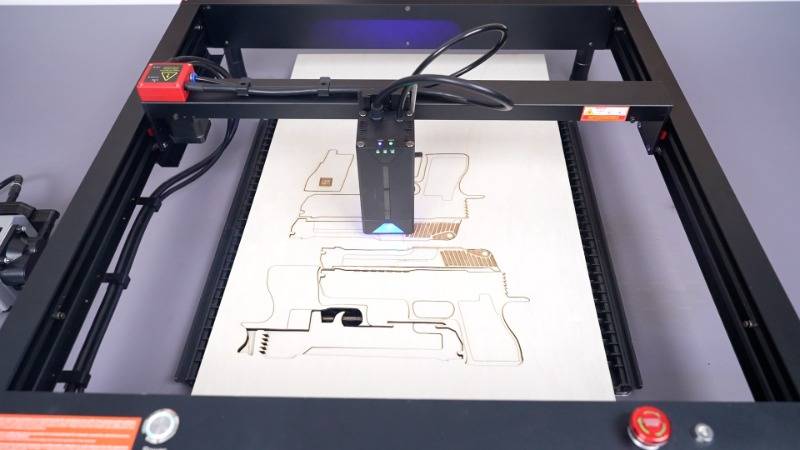

AlgoLaser Delta, equipped with cutting-edge diode laser technology, complements LightBurn's functionality to deliver exceptional results in plywood crafting. Here's a step-by-step guide on how to laser engrave and cut on plywood using AlgoLaser Delta and LightBurn:

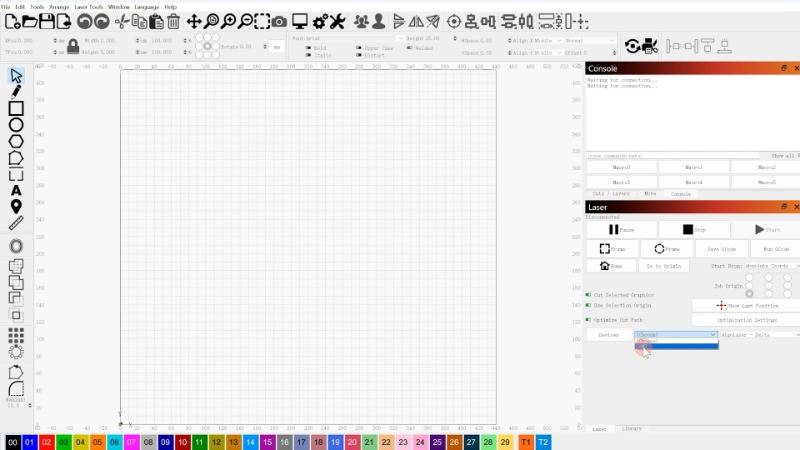

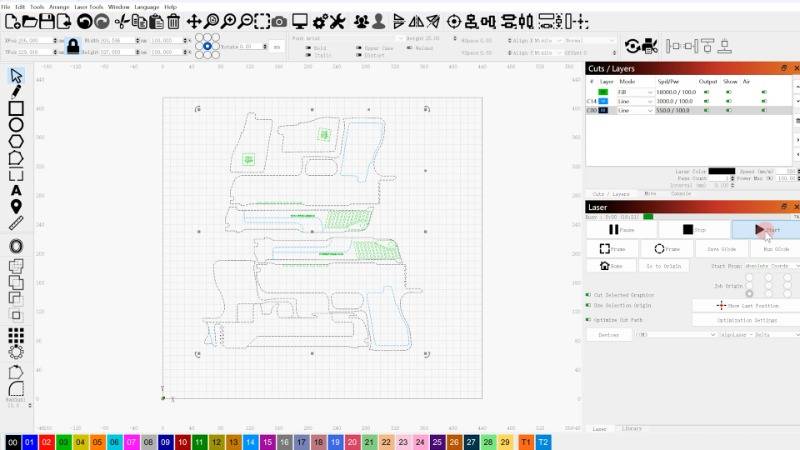

Step 2, open the LightBurn.

Choose the corresponding machine.

Wait for the console to display "OK".

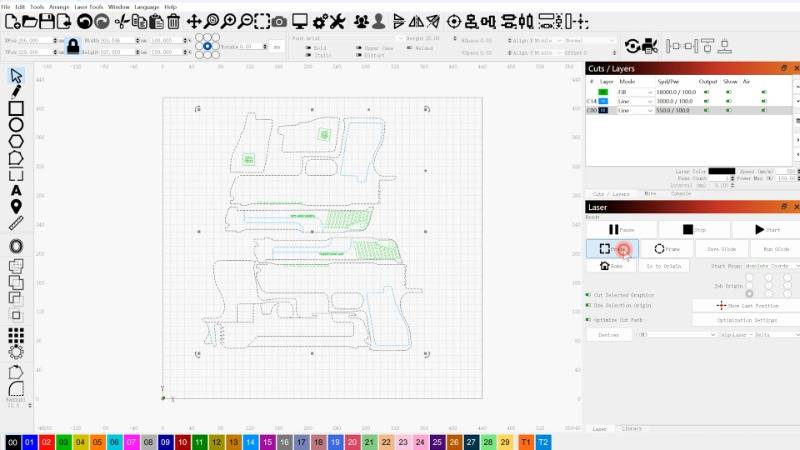

Step 3, drag the prepared pattern into the workspace.

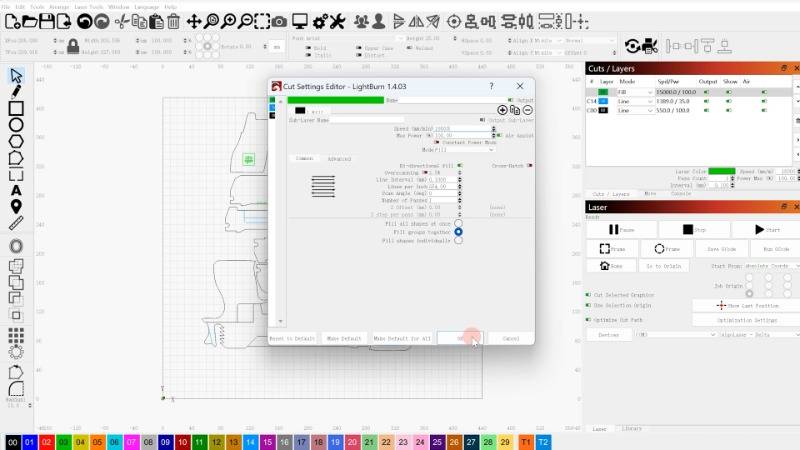

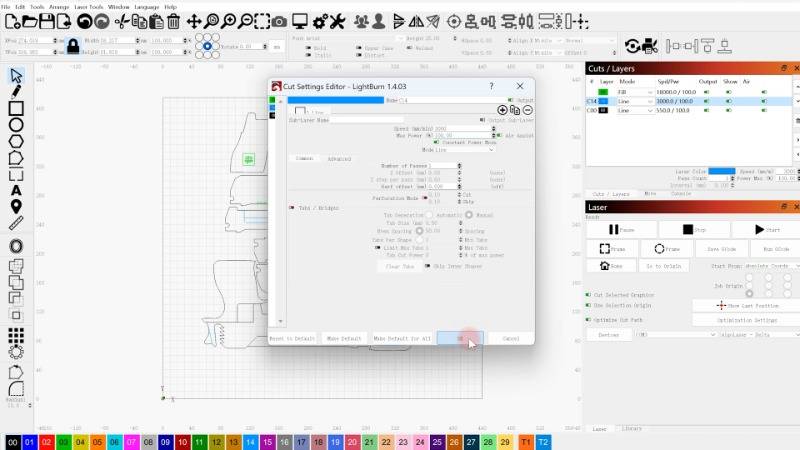

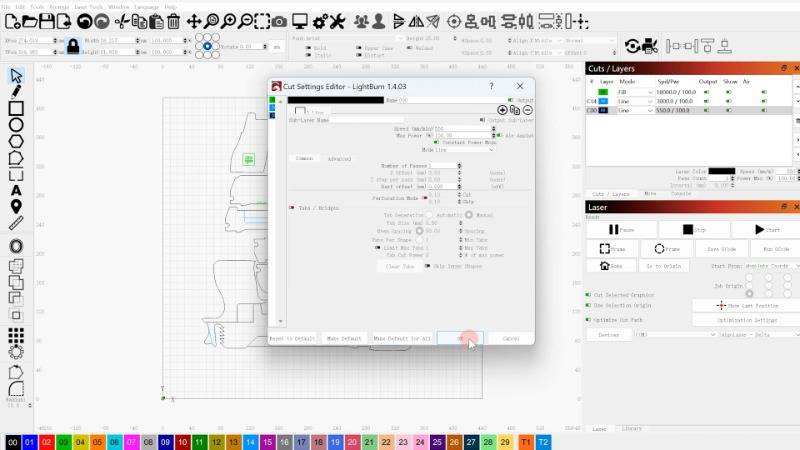

Click on the console to set engraving and cutting parameters.

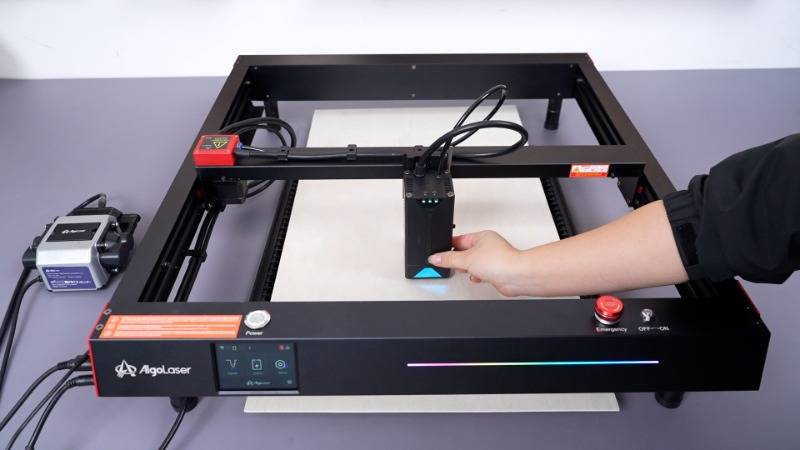

Step 4, click "Frame" button to determine the processing area.

Step 5, click "Start".

FAQs About Laser Cut on Plywood

What types of plywood are suitable for laser cutting?

Plywood with a smooth surface and minimal voids is ideal for laser cutting to ensure clean and precise results.

How thick of plywood can be cut with a diode laser engraving machine?

Diode laser engraving machines like AlgoLaser Delta can typically cut plywood up to a thickness of 6mm, depending on the power and focal depth settings.

Can intricate designs be laser cut on plywood?

Yes, intricate designs can be laser cut on plywood with precision, thanks to the accuracy and versatility of diode laser engraving machines.

How can I prevent charring or burning when laser cutting plywood?

To minimize charring or burning, ensure that the laser power and speed settings are optimized for the specific type and thickness of plywood being used.

Is it possible to engrave photographs onto plywood using a laser engraver?

Yes, laser engravers can engrave high-resolution photographs onto plywood, capturing intricate details and producing visually stunning results.

What safety precautions should be taken when operating a laser cutter?

Operators should wear appropriate personal protective equipment, ensure proper ventilation in the workspace, and follow all safety guidelines provided by the manufacturer.

Conclusion

The integration of diode laser engraving machines like AlgoLaser Delta with LightBurn software opens up a world of possibilities in plywood crafting. Whether you're a hobbyist, artist, or entrepreneur, the precision and efficiency offered by this technology can elevate your projects to new heights. By mastering the art of Delta Cut with LightBurn, you can unleash your creativity and explore endless design opportunities in plywood crafting. So, embrace the potential of laser engraving and cutting, and embark on a journey of innovation and craftsmanship in the realm of woodworking.

- Choosing a selection results in a full page refresh.