Choosing the Right Laser Engraver: A Comprehensive Guide for Hobbyists, Businesses, and Professionals

Laser engraving is an incredible technology that has revolutionized the way we approach customization and fabrication. From creating personalized gifts to producing intricate designs on industrial components, the possibilities with a laser engraver are limitless. But with so many options on the market, how do you choose the right one for your needs? Whether you're a hobbyist looking for your first machine or a business aiming to scale production, understanding the differences between various laser engravers is crucial.

We'll explore the key types of laser engravers, their advantages and disadvantages, and provide a guide to help you choose the perfect one based on your goals.

What is a Laser Engraver?

A laser engraver is a device that uses a laser beam to engrave or cut materials. The laser focuses a high-powered light on the surface of the material, causing it to burn, melt, or vaporize in a precise pattern. Laser engraving is popular in a variety of industries, from crafting and art to manufacturing and production. Different types of lasers, such as diode lasers, CO2 lasers, and fiber lasers, are used depending on the material to be engraved and the intended purpose.

Types of Laser Engravers

Laser engravers can be categorized based on the technology they use and their suitability for different materials. The three main types are diode lasers, CO2 lasers, and fiber lasers. Each comes with its unique features, making them ideal for different applications.

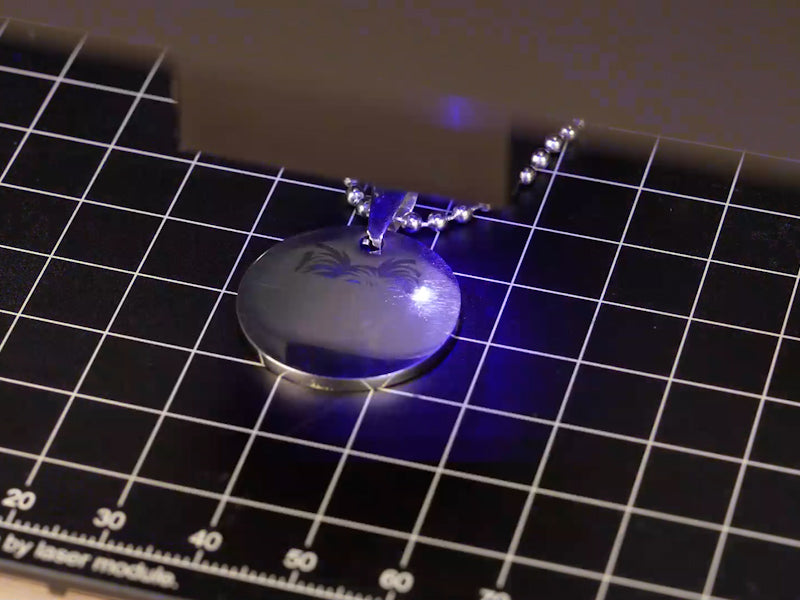

1. Diode Laser Engravers

Diode laser engravers are the most affordable and accessible option for hobbyists, small businesses, and DIY enthusiasts. These engravers use a diode to generate a laser beam that is directed onto the material to engrave or cut.

Advantages of Diode Laser Engravers:

· Affordability: Diode lasers are budget-friendly, with prices ranging from $200 to $1,500, making them ideal for hobbyists or those just starting out.

· Compact Size: These machines are typically small and lightweight, allowing them to fit into smaller workspaces.

· Low Power Consumption: Diode lasers are energy-efficient, consuming less power than their CO2 and fiber counterparts.

· Ease of Use: They are generally easy to set up and operate, with user-friendly interfaces and straightforward software integration.

· Material Compatibility: Diode lasers work well with a range of materials, including wood, leather, acrylic, and some soft metals.

Disadvantages of Diode Laser Engravers:

· Limited Power: While they excel in engraving, their cutting ability is limited, especially for thicker or harder materials.

· Slower Cutting Speed: Diode lasers are slower than more powerful systems like CO2 or fiber lasers, especially when cutting through dense materials.

· Material Limitations: They are not suitable for engraving on hard metals, stone, or thicker materials that require high power.

Best for: Hobbyists, crafters, and small businesses focusing on engraving and cutting lightweight materials.

2. CO2 Laser Engravers

CO2 laser engravers are a more powerful option than diode lasers, making them perfect for engraving and cutting a wider variety of materials, from wood and acrylic to leather and some metals.

Advantages of CO2 Laser Engravers:

· Versatility: CO2 lasers can handle a wide range of materials, including wood, acrylic, leather, and some metals.

· Precision: Known for their fine detail and precision, CO2 lasers are ideal for intricate engraving and cutting.

· Faster Speed: CO2 lasers are faster than diode lasers, allowing for quicker processing, especially when cutting through non-metal materials.

· Higher Power Options: With power ranges typically between 40W and 150W, CO2 lasers can handle thicker materials, making them more suitable for commercial use.

Disadvantages of CO2 Laser Engravers:

· Size and Weight: These machines tend to be larger and heavier than diode lasers, requiring more space in your workshop.

· Higher Cost: Prices for CO2 lasers can range from $1,000 to $8,000, depending on the power and capabilities of the machine.

· Material Limitations: While they perform well on wood and acrylic, CO2 lasers are not as effective on metals as fiber lasers.

Best for: Small businesses, educational institutions, and professional artists who need versatility and precision on non-metal materials.

3. Fiber Laser Engravers

Fiber laser engravers are the top choice for industrial applications and professional users, especially those working with metals. They use fiber optic technology to generate a highly focused laser beam, delivering exceptional speed and precision.

Advantages of Fiber Laser Engravers:

· Metal Cutting and Engraving: Fiber lasers excel at engraving and cutting metals such as stainless steel, aluminum, and titanium with high precision.

· High Speed: Fiber lasers are the fastest of the three types, providing quick turnaround times for cutting and engraving jobs.

· Low Maintenance: These lasers have fewer moving parts and require less maintenance than CO2 lasers.

· Energy Efficiency: Fiber lasers use significantly less power than CO2 lasers, making them more energy-efficient.

· Long Lifespan: A well-maintained fiber laser can last for over 100,000 hours, making it a solid investment for heavy-duty commercial or industrial use.

Disadvantages of Fiber Laser Engravers:

· High Initial Cost: Fiber lasers are the most expensive option, with prices starting at around $5,000 and reaching upwards of $50,000 depending on the power and features.

· Limited Material Compatibility: Fiber lasers are best suited for metals and are not effective on non-metal materials like wood or acrylic.

· Smaller Cutting Area: Compared to CO2 lasers, fiber lasers generally offer a smaller working area.

Best for: Large manufacturers, metalworking shops, and businesses that require high precision and fast cutting speeds, especially for metal engraving.

Choosing the Right Laser Engraver for Your Needs

Now that we've covered the basics of diode, CO2, and fiber lasers, let's dive into how to choose the right one based on your specific requirements.

1. Budget Considerations

Your budget is one of the most important factors when selecting a laser engraver. If you're a hobbyist or just starting, a diode laser engraver will provide an affordable and effective solution. However, for professional businesses or industrial applications, a CO2 or fiber laser will offer more power and versatility, though at a higher cost.

2. Material Type

· Wood, Acrylic, Leather, and Other Soft Materials: A CO2 laser engraver is the best choice for engraving and cutting non-metal materials. It offers versatility and precision for detailed designs.

· Metals: If you plan to work with metals, a fiber laser engraver is the superior option due to its power and speed when working with tougher materials.

· Multiple Materials: If you need a machine that can handle a variety of materials, a CO2 laser provides a balance of power, speed, and material compatibility.

3. Work Volume and Space

· Small Projects and Space Constraints: If you're limited on space, a diode laser engraver is compact and ideal for small-scale projects.

· Larger Projects and Production: A CO2 laser engraver is perfect for medium to large-scale projects, but you'll need more workspace.

· Industrial-Scale Production: For high-volume manufacturing, a fiber laser engraver or CNC laser cutter is ideal, but these machines require significant space and investment.

4. Speed and Precision Needs

· Quick Turnaround and Efficiency: Fiber lasers are the fastest option, perfect for large-scale production where speed is essential.

· High Precision for Art or Fine Detail: If your work requires intricate, high-precision engraving, CO2 lasers are the best choice for non-metal materials.

Comparison Table: Diode Laser, CO2 Laser, and Fiber Laser Engravers

| Feature | Diode Laser Engraver | CO2 Laser Engraver | Fiber Laser Engraver |

|---|---|---|---|

| Price Range | $200 - $1,500 | $1,000 - $8,000 | $5,000 - $50,000+ |

| Power | Low (typically 1W to 40W) | Medium (40W to 150W) | High (up to 500W or more) |

| Material Compatibility | Wood, leather, acrylic, paper, some metals (soft) | Wood, acrylic, leather, glass, fabric, and some metals | Metals (steel, aluminum, titanium), some plastics |

| Cutting Speed | Slow, especially on thick materials | Faster than diode lasers, especially for non-metals | Fastest, especially for metals and thick materials |

| Precision | Good for fine details on softer materials | High precision on a wide range of materials | Very high precision, especially on metals |

| Maximum Material Thickness | Thin materials (up to 5mm, depending on power) | Medium (up to 25mm or more for wood and acrylic) | High (up to 20mm+ for metal, depending on power) |

| Ease of Use | Very easy to use, ideal for beginners | Moderate (requires setup and understanding of materials) | More advanced, requires expertise in setup and operation |

| Maintenance | Low maintenance, minimal parts | Moderate maintenance (mirror alignment, lens cleaning) | Very low maintenance, long lifespan, fewer parts to replace |

| Speed (Cutting/Engraving) | Slow (best for smaller, detailed work) | Faster (great for medium-sized projects) | Very fast (ideal for high-volume production) |

| Best For | Hobbyists, DIY projects, small-scale engraving | Small businesses, artists, schools, and makers | Industrial applications, metal engraving, high-volume businesses |

| Space Requirement | Compact, fits easily in small spaces | Medium size, requires more workspace | Larger, needs significant space |

Final Thoughts

Whether you're engraving custom designs for a business, working on creative projects as a hobbyist, or producing industrial components, selecting the right laser engraver is key to achieving the results you desire. By considering your budget, the materials you plan to work with, and your speed and precision requirements, you'll be well on your way to choosing the perfect laser engraver for your needs.

From diode lasers for beginners to fiber lasers for industrial applications, the right machine will unlock endless possibilities for cutting, engraving, and crafting with precision. So, which laser will you choose to bring your creations to life?