How Alpha Engraves on Stainless Steel with LightBurn

Stainless steel is a remarkable material known for its durability, resistance to corrosion, and sleek appearance. Laser engraving on stainless steel opens up a world of creative possibilities, allowing for intricate designs, precise markings, and durable inscriptions. There are several types of laser engraving techniques that can be employed on stainless steel materials, each offering unique advantages and aesthetic effects.

Types of Laser Engraving on Stainless Steel Materials

1. Surface Etching

Surface etching is a popular technique used for engraving on stainless steel, particularly for decorative purposes. In surface etching, the laser beam removes a thin layer of material from the surface of the stainless steel, creating a contrasting mark. This method is ideal for adding logos, text, or intricate designs to stainless steel items such as plaques, jewelry, and signage. Surface etching produces a clean, crisp engraving without compromising the structural integrity of the stainless steel.

2. Deep Engraving

Deep engraving involves penetrating the surface of the stainless steel to create more pronounced markings. This technique is often used for industrial applications where durability and readability are essential. Deep engraving is commonly employed for engraving serial numbers, part numbers, or identification tags on stainless steel components. By adjusting the laser parameters, engravers can control the depth of the engraving to achieve the desired effect. Deep engraving produces bold, durable markings that are resistant to wear and tear, making it suitable for harsh environments.

3. Annealing

Annealing is a unique laser engraving technique that utilizes heat to alter the color of the stainless steel surface. Unlike surface etching or deep engraving, annealing does not remove material from the surface but instead induces a localized change in the metal's properties. By carefully controlling the laser's intensity and duration, engravers can create intricate patterns, designs, or text on stainless steel surfaces. Annealing produces a visually striking contrast between the engraved areas and the surrounding material, making it popular for decorative and artistic applications.

4. Color Marking

Color marking is a specialized laser engraving technique that involves depositing pigments or dyes onto the stainless steel surface to create colorful designs or markings. This method is often used for decorative or branding purposes, allowing for vibrant and eye-catching engravings on stainless steel items such as promotional products, awards, and consumer goods. Color marking can be achieved using a variety of laser technologies, including fiber lasers and CO2 lasers, depending on the desired effect and substrate material.

5. Foam Marking

Foam marking is a versatile laser engraving technique that involves creating a frosted or textured effect on the stainless steel surface. This method is achieved by adjusting the laser parameters to produce controlled surface oxidation, resulting in a matte finish. Foam marking is often used for adding texture or dimension to stainless steel items such as nameplates, control panels, or decorative accents. This technique can enhance the visual appeal of the engraving while providing a tactile experience for the end-user.

The Role of LightBurn in Laser Engraves on Stainless Steel

LightBurn is a powerful software solution designed specifically for laser engraving and cutting, offering a wide range of features and capabilities to enhance the engraving process on stainless steel and other materials. At its core, LightBurn provides intuitive design tools that allow users to create intricate artwork, text, and graphics with ease.

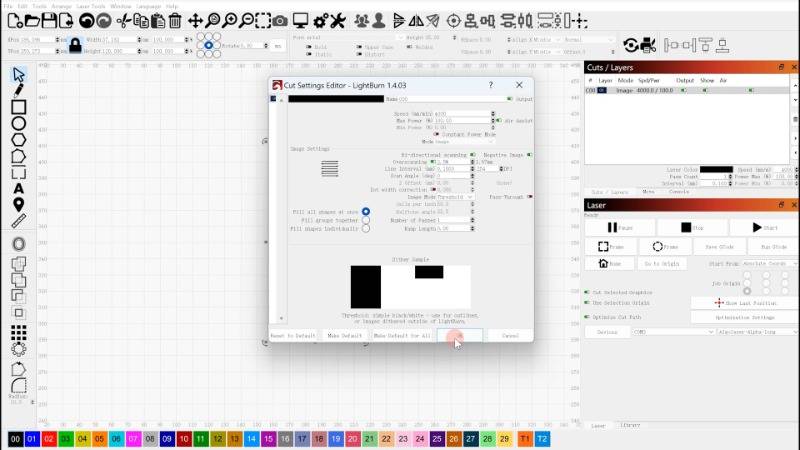

One of the key features of LightBurn is its advanced control over laser parameters, including power, speed, and focal depth. This level of precision enables users to achieve consistent and high-quality results when engraving on stainless steel, ensuring crisp and accurate markings every time. Additionally, LightBurn offers real-time preview functionality, allowing users to visualize their designs before sending them to the laser engraver, minimizing errors and optimizing workflow efficiency.

LightBurn also supports a wide range of file formats, including vector graphics and raster images, giving users the flexibility to work with their preferred design software and import files seamlessly into the application. This compatibility ensures that engravers can leverage existing designs and artwork without the need for extensive conversion or modification.

Furthermore, LightBurn offers comprehensive support for diode laser engraving machines, including those used by Alpha Engraves. This compatibility ensures seamless integration between the software and hardware, allowing for smooth communication and precise control over the engraving process. Whether engraving intricate designs or cutting through stainless steel materials, LightBurn provides the tools and functionality needed to achieve exceptional results with ease.

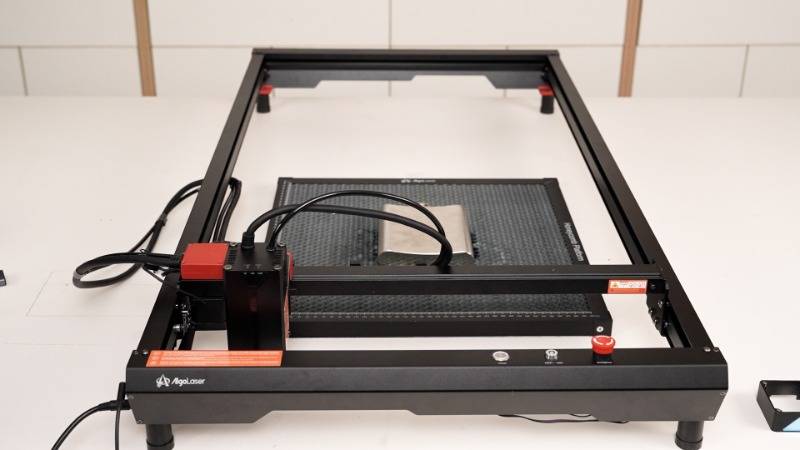

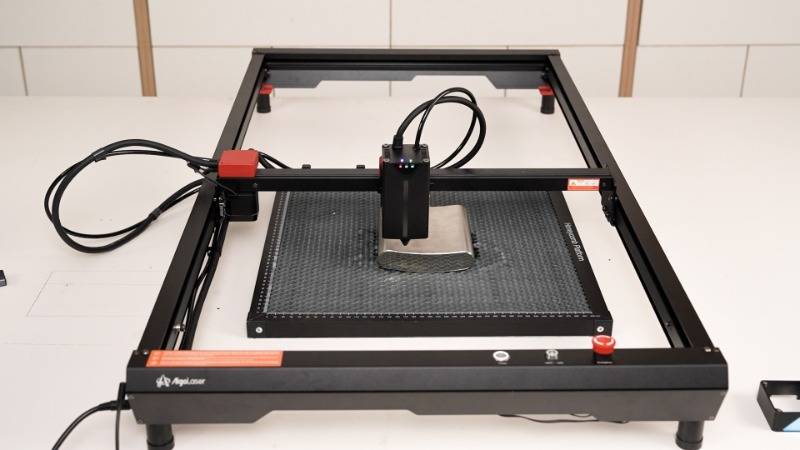

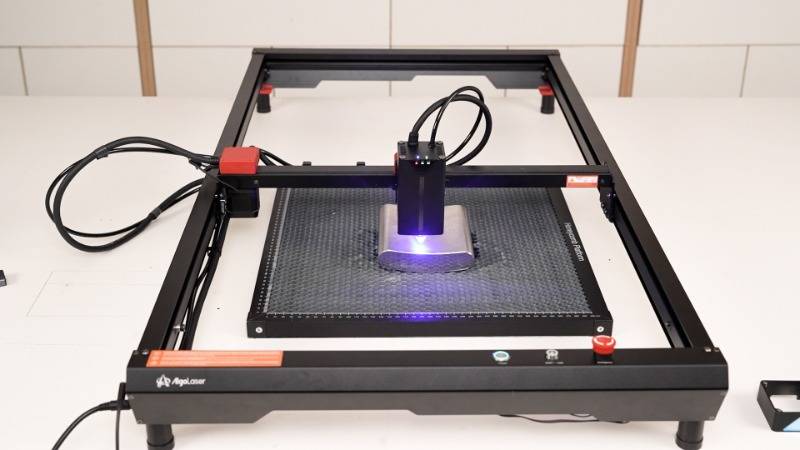

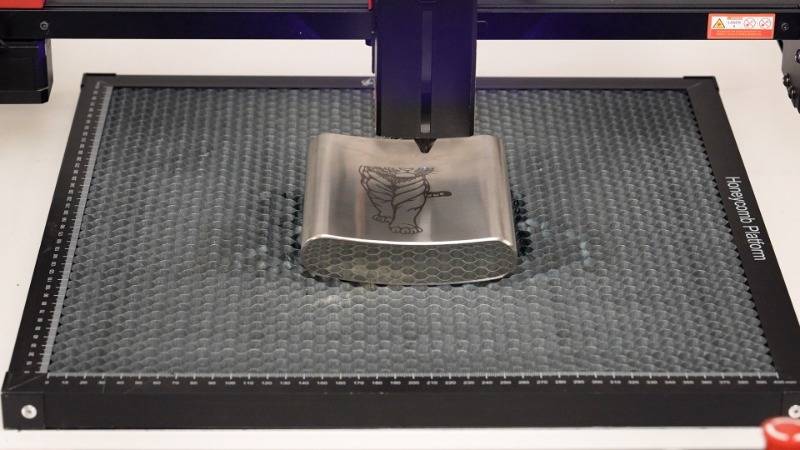

How Alpha Engraves on Stainless Steel with LightBurn by AlgoLaser Alpha

Alpha Engraves, powered by AlgoLaser Alpha, exemplifies excellence in stainless steel engraving with LightBurn.

Step 1, power on the machine, get the focus right.

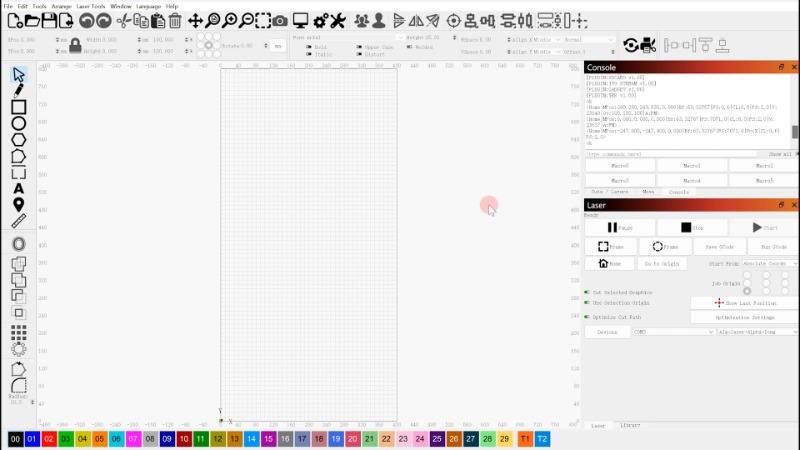

Step 2, open the LightBurn. Choose the corresponding machine. Wait for the console to display "OK" .

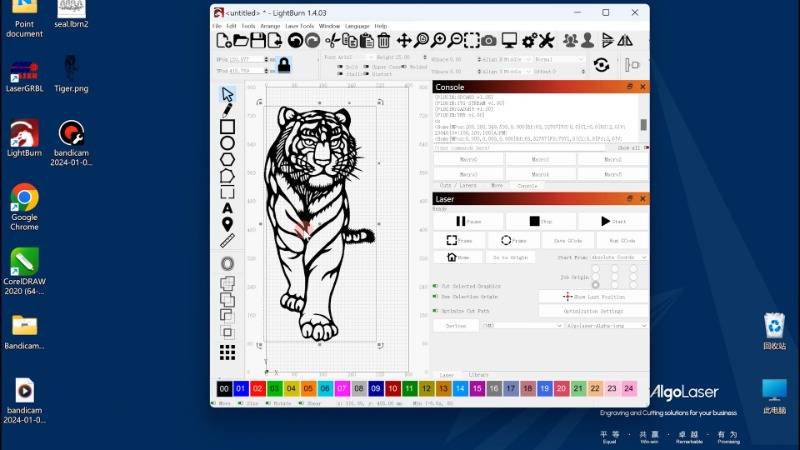

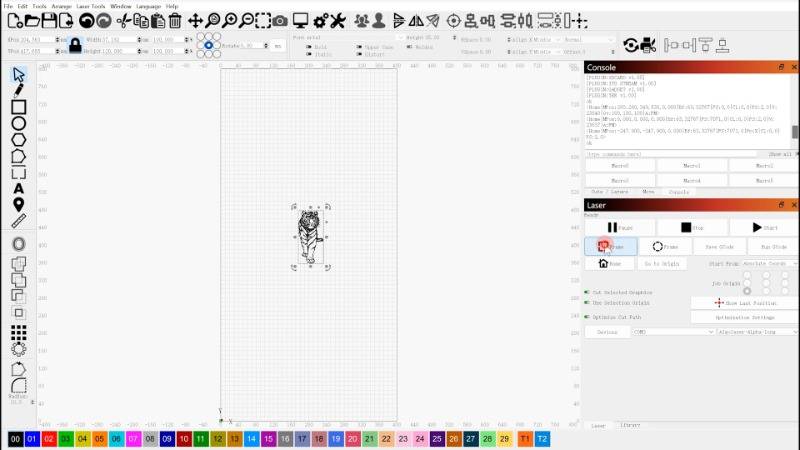

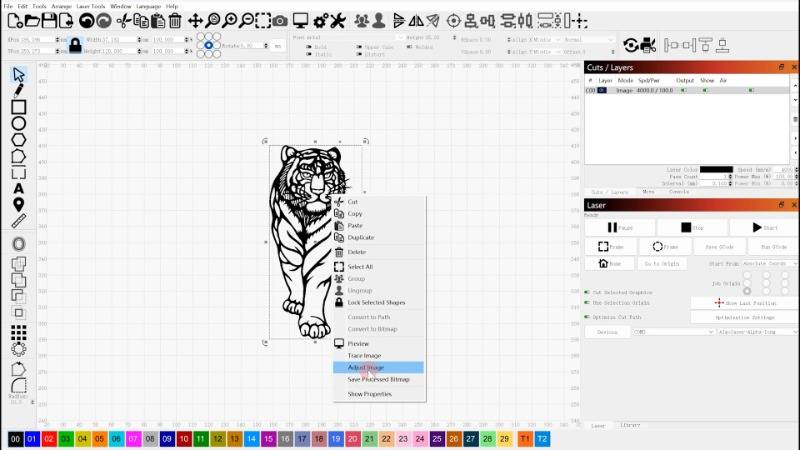

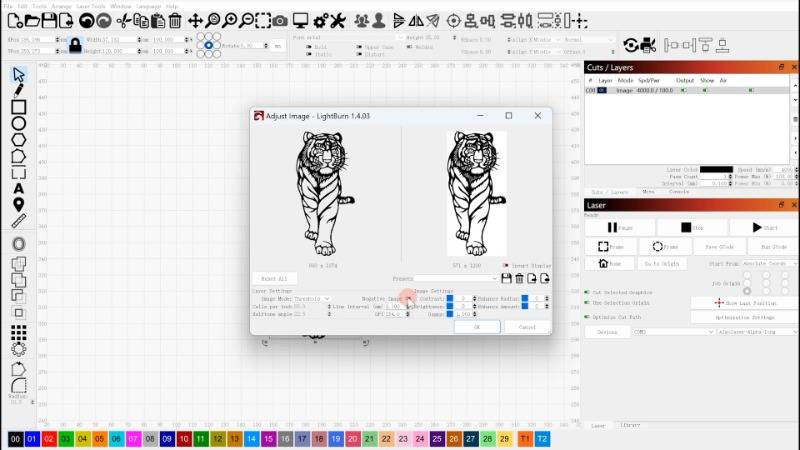

Step 3, drag the prepared pattern into the workspace. Setting the image size.

Step 4, click "Frame" button to determine the processing area. Click on the console to set the engraving parameters. Click "Adjust Image" .

Step 5, click "Start" .

FAQs About Laser Engraving on Stainless Steel

What type of laser engraver is best for engraving on stainless steel?

Diode laser engravers are well-suited for engraving on stainless steel due to their high precision and versatility.

Can laser engraving on stainless steel withstand outdoor conditions?

Yes, laser engraving on stainless steel is highly durable and resistant to outdoor elements, making it suitable for signage and other outdoor applications.

How deep can laser engraving penetrate into stainless steel?

The depth of laser engraving on stainless steel can vary depending on factors such as laser power and material thickness, but typically ranges from surface etching to several millimeters deep.

Is annealing a permanent form of engraving on stainless steel?

Yes, annealing alters the color of the stainless steel surface permanently, creating a long-lasting and visually striking engraving.

Can intricate designs be engraved on stainless steel with a laser engraver?

Yes, laser engravers equipped with advanced software like LightBurn can engrave intricate designs, text, and graphics with precision and clarity on stainless steel surfaces.

How can I ensure the longevity of laser engravings on stainless steel?

Properly maintaining and cleaning the engraved surface can help preserve the integrity and longevity of laser engravings on stainless steel.

Conclusion

In conclusion, mastering the art of stainless steel engraving with LightBurn opens up a world of possibilities for creativity and innovation. Whether it's crafting personalized gifts, adding branding elements to industrial components, or creating intricate artworks, the combination of advanced technology and precise software facilitates limitless potential. As exemplified by Alpha Engraves, laser engraving on stainless steel with LightBurn is not just a skill but a testament to craftsmanship and ingenuity.

- Choosing a selection results in a full page refresh.