How Alpha Engraves on Leather with LightBurn

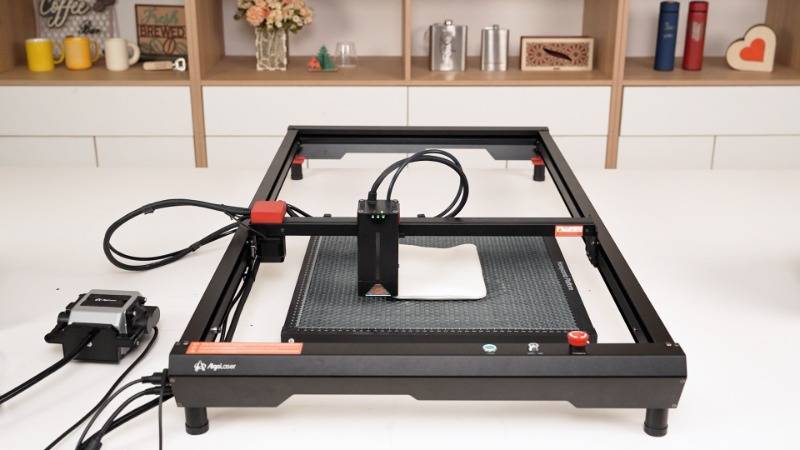

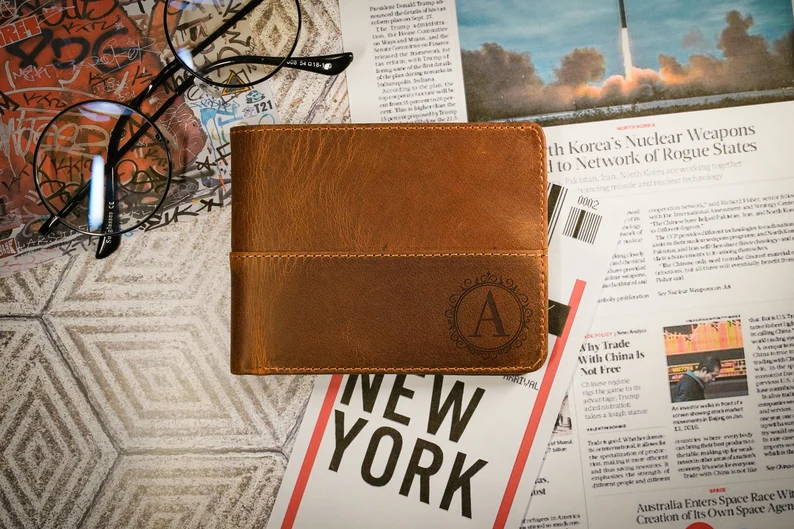

Leather engraving has become a popular choice for adding personalized touches to various items, ranging from wallets and bags to bracelets and keychains. With the advent of technology, laser engraving has emerged as the go-to method for achieving precise and intricate designs on leather surfaces. We will delve into the world of laser engraving on leather materials, focusing on the utilization of LightBurn software with AlgoLaser Alpha, a diode laser engraving machine.

Types of Laser Engraving on Leather Materials

Laser engraving on leather materials offers a plethora of options for customization and personalization. The versatility of laser technology allows for various techniques to achieve different effects on leather surfaces. Let's explore the three primary types of laser engraving on leather:

Surface Engraving

Surface engraving is one of the most common techniques used on leather. In this method, the laser beam interacts with the surface of the leather, altering its appearance without penetrating deeply. Surface engraving creates a contrast between the engraved area and the untouched surface of the leather, resulting in visually striking designs. This technique is ideal for adding logos, text, or intricate patterns to leather products such as wallets, keychains, or phone cases. Surface engraving can be subtle or bold, depending on the desired effect and the laser settings used.

Deep Engraving

Deep engraving involves penetrating the surface of the leather to create a more pronounced effect. Unlike surface engraving, which only alters the top layer of the leather, deep engraving goes deeper into the material, resulting in a more tactile and textured finish. This technique is commonly used for creating bold designs, 3D reliefs, or decorative elements with depth and dimension. Deep engraving is particularly suitable for leather products where a tactile or embossed effect is desired, such as belts, bracelets, or book covers. By adjusting the laser power and speed, users can control the depth of engraving to achieve the desired outcome.

Cutting

Laser cutting is another popular application of laser technology on leather materials. Unlike engraving, which alters the surface of the leather, cutting involves removing sections of the material to create precise shapes and patterns. Laser cutting offers unparalleled precision and accuracy, allowing for the creation of intricate designs that would be challenging to achieve with traditional cutting methods. This technique is commonly used for producing leather patches, inlays, or appliqués for various products such as garments, accessories, or footwear. Laser cutting can be combined with engraving to create intricate designs with both engraved and cut elements on the same piece of leather.

The Role of LightBurn in Laser Engraves on Leather

LightBurn is a powerful software solution designed specifically for laser engraving machine. Its intuitive interface and extensive features make it an ideal companion for the AlgoLaser Alpha in engraving on leather. This section will discuss the key functionalities of LightBurn, including:

Design Import and Manipulation

LightBurn allows users to import various file formats, such as SVG and DXF, and manipulate designs with ease, enabling precise placement and scaling.

Control Parameters

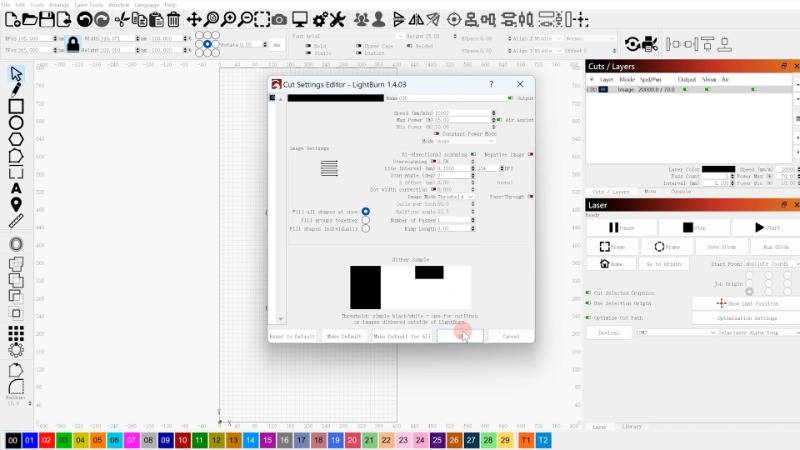

With LightBurn, users can adjust laser power, speed, and other parameters to achieve the desired engraving depth and clarity on leather.

Preview and Simulation

The software offers a preview mode, allowing users to simulate the engraving process before execution, ensuring accurate results and minimizing errors.

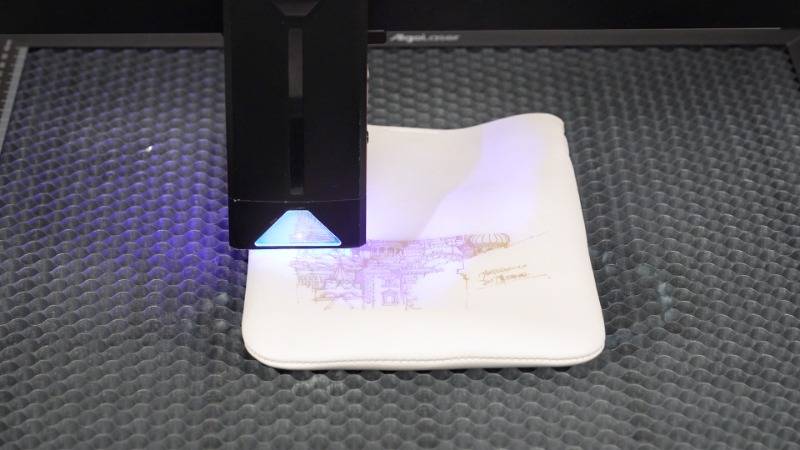

How To Laser Engrave and Engraves on Leather with LightBurn by AlgoLaser Alpha

This section will provide a step-by-step guide on how to laser engrave and cut leather using LightBurn with the AlgoLaser Alpha machine. The process will cover:

Step 1, power on the machine, and wait for the module stopping at the original point.

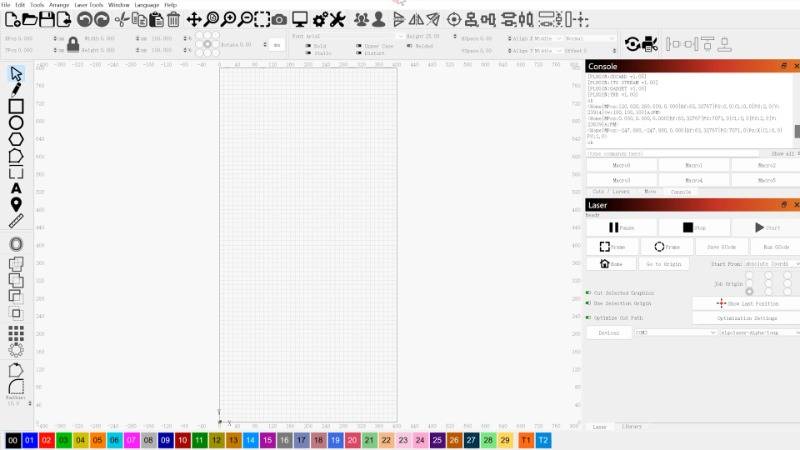

Step 2, open the LightBurn. Wait for the console to display "OK" .

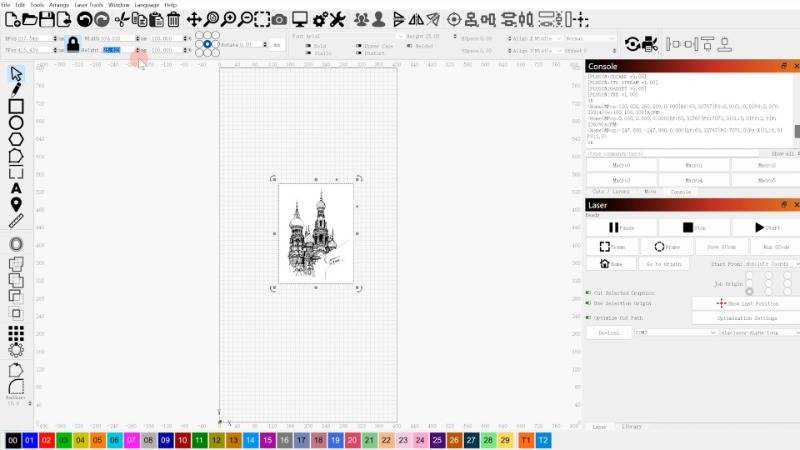

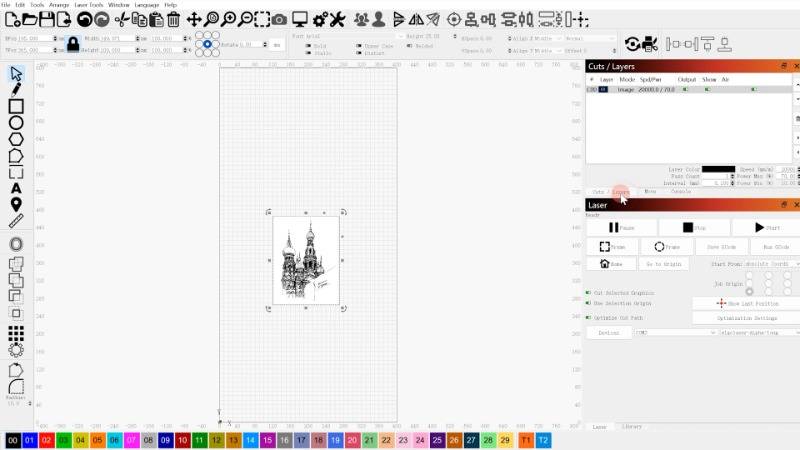

Step 3, drag the prepared pattern into the workspace. Setting the image size. Moving the picture to the right position. Click on the console to set the engraving parameters.

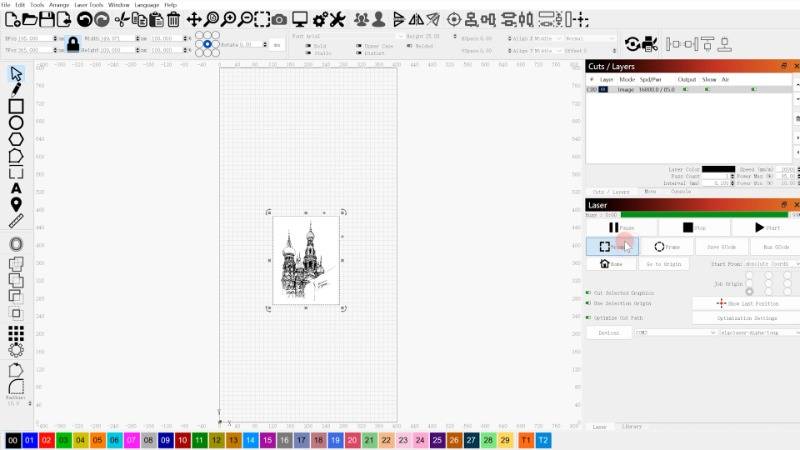

Step 4, click "Frame" button to determine the processing area.

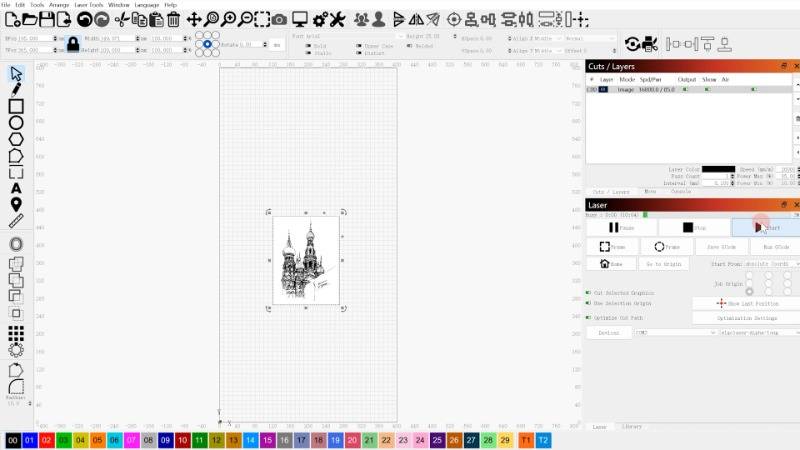

Step 5, click "Start" .

FAQs About Laser Engraving on Leather

Laser engraving on leather is a fascinating process that opens up a world of creative possibilities for artisans, designers, and enthusiasts alike. However, it's natural for beginners and even experienced users to have questions about this innovative technique. Here are more than six frequently asked questions (FAQs) about laser engraving on leather, along with detailed answers:

What types of leather are suitable for laser engraving?

Laser engraving can be performed on various types of leather, including but not limited to cowhide, sheepskin, goatskin, and even synthetic leather. However, it's essential to consider the quality and finish of the leather, as well as any coatings or treatments applied to the surface. Smooth, untreated leather typically yields the best results, as it allows for crisp and clear engraving without interference from coatings or textures.

Is laser engraving permanent on leather?

Yes, laser engraving on leather is permanent. The laser beam physically alters the surface of the leather by either removing material (in the case of cutting) or causing localized discoloration (in the case of engraving). Once engraved, the design becomes an integral part of the leather and is resistant to fading, peeling, or rubbing off over time.

How deep can laser engraving penetrate into leather?

The depth of laser engraving into leather can vary depending on several factors, including the type and thickness of the leather, the power and speed settings of the laser, and the desired outcome. Surface engraving typically penetrates only a fraction of a millimeter into the leather, while deep engraving can go several millimeters deep, creating a more pronounced effect. Laser cutting, on the other hand, can penetrate through the entire thickness of the leather, allowing for precise cutting of shapes and patterns.

Can intricate designs be achieved with laser engraving on leather?

Yes, laser engraving is incredibly versatile and capable of producing intricate designs with high precision and detail. Modern laser engraver, coupled with advanced software like LightBurn, allow users to create and engrave intricate patterns, fine text, and complex images with ease. The level of detail achievable depends on factors such as the resolution of the design file, the laser's capabilities, and the quality of the leather surface.

What safety precautions should be taken when laser engraving leather?

Safety is paramount when working with laser engraving machines. Some essential safety precautions to follow when laser engraving on leather include:

Wearing appropriate personal protective equipment (PPE), such as safety glasses, to protect against laser radiation and flying debris.

Ensuring proper ventilation in the workspace to remove smoke and fumes generated during the engraving process.

Following manufacturer guidelines and recommendations for operating the laser engraving machine safely, including proper machine setup, maintenance, and emergency procedures.

How to maintain and clean laser-engraved leather products?

Laser-engraved leather products require minimal maintenance to preserve their appearance and longevity. To clean laser-engraved leather, gently wipe the surface with a soft, dry cloth to remove any dust or debris. For more stubborn stains or dirt, lightly dampen the cloth with water and mild soap, then gently wipe the affected area. Avoid using harsh chemicals or abrasive cleaners, as they can damage the engraved surface or alter its appearance. Additionally, store laser-engraved leather products away from direct sunlight and excessive heat to prevent fading or discoloration over time.

Can laser engraving on leather be used for personal or commercial purposes?

Yes, laser engraving on leather can be utilized for both personal and commercial purposes. Many individuals and businesses use laser engraving to customize leather products such as wallets, belts, bags, and accessories with names, logos, artwork, or other designs. From personalized gifts to branded merchandise, laser-engraved leather products add a touch of elegance and uniqueness that resonates with customers and recipients alike.

Conclusion

In conclusion, laser engraving with LightBurn and the AlgoLaser Alpha machine offers a versatile and precise method for customizing leather products. Whether it's adding intricate designs, personalizing gifts, or creating unique accessories, the combination of advanced technology and user-friendly software makes leather engraving accessible to enthusiasts and professionals alike. With proper techniques and attention to detail, the possibilities for creativity are endless in the realm of laser engraving on leather.

- Choosing a selection results in a full page refresh.