How to adjust Alpha laser engraver to the best engraving performance?

Check as following steps.

1. X-axis Gantry Adjustment

X-axis gantry is most likely not parallel to the front and rear frames, you need to refer to this video to re-adjust your gantry.

Related video link address:

https://drive.google.com/file/d/1Gp6d6ZY1o-QbbVCrxZVXWsSf6WCaH3EF/view?usp=drive_link

2. Belt Adjustment

Refer to following video. Our advice would be to completely remove the screws and install it again, starting from scratch tends to be less misguided.

Related video link address:

https://www.youtube.com/watch?v=Y1BKN4ECZgg&list=PLoXeRVaWUkNL15Z8xHS0aLSyMM_qjklAO&index=8&pp=iAQB

3. Coupling Adjustment

Ensure that the gap in the coupling and the connection point of the left and right motor extension shaft are aligned.

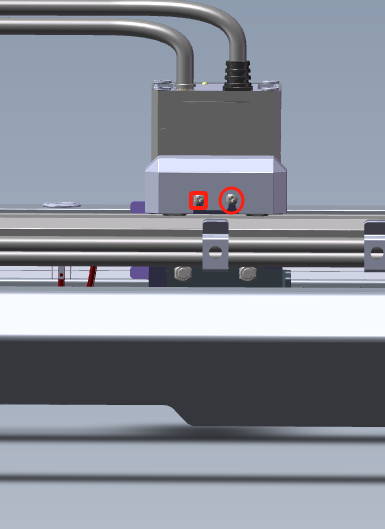

4. Eccentric Nut Adjustment

It will make the machine run perfect. Please follow the steps to adjust the eccentric nut.

The positions to be adjusted are the x-axis and y-axis, located behind the z-axis backplate (screws need to be unscrewed) and the backplates at the ends of the x-gantry, respectively.

4.1 The screws on the back of the z-axis backplate, first you need to unscrew the housing screws.

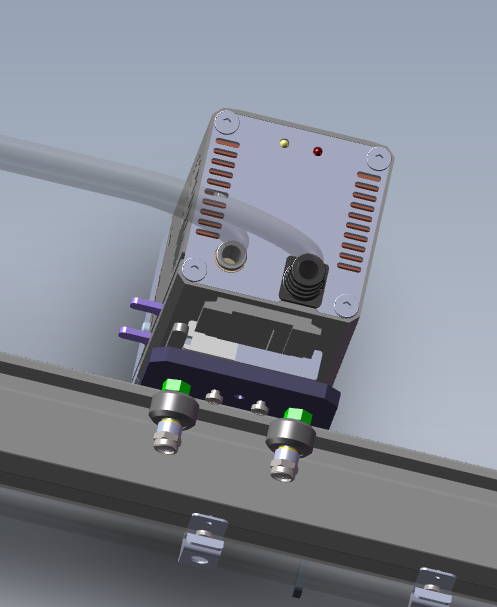

4.2 y-axis position of the eccentric nut to be adjusted

Left position of the eccentric nut, please remember to move the cable of laser engraver for easy adjustment.

The eccentric nut is responsible for adjusting the degree of looseness or tightness between the rollers and the rail.

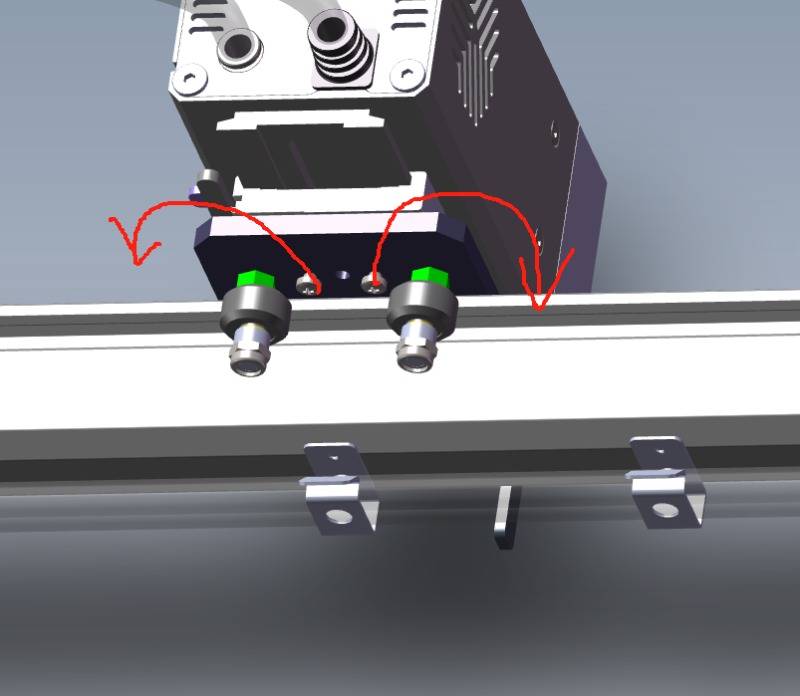

4.3 Adjustment

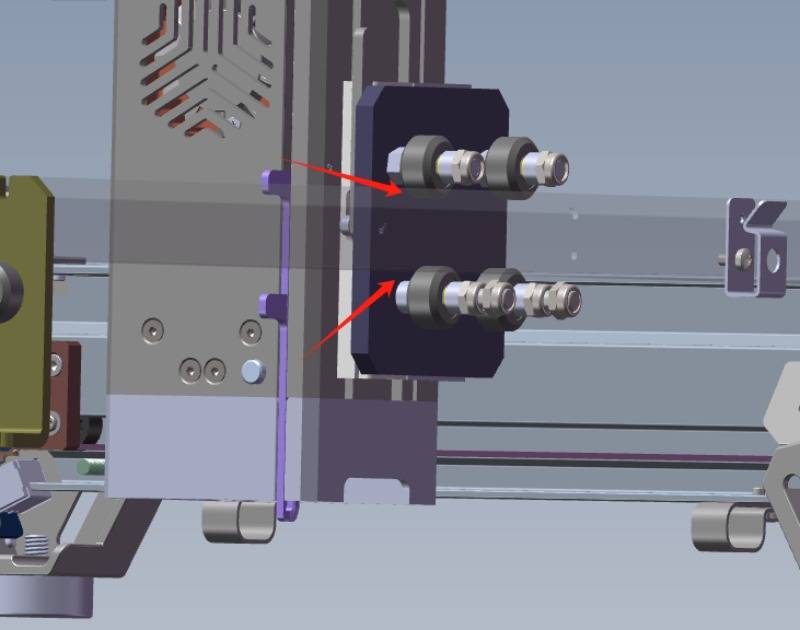

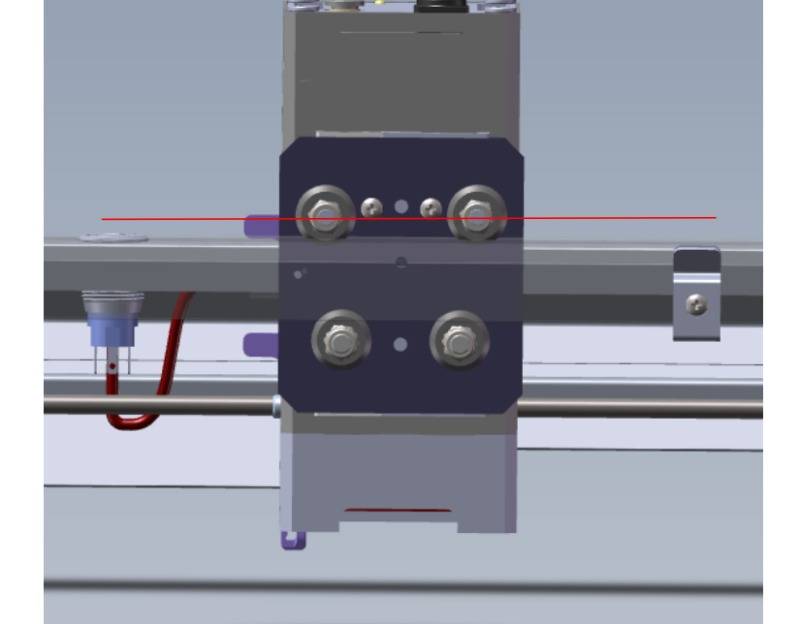

The direction of the rollers on the left and right sides need to be in different directions in order to achieve the effect of loosening or tightening at the same time. As shown in the picture

4.4 Criteria for determining tightness

The two rollers snap right out of the rail, not too tight nor remaining space.

4.5 Caution

It must be ensured that the nuts at both ends are on the same level.

Free SVG & Gcode Files for Laser Engraving & Cutting can be found here, wich you can import into our laser cutters directly.

- Choosing a selection results in a full page refresh.