Acrylic Engraving and Cutting with Delta Laser Engraver and LightBurn

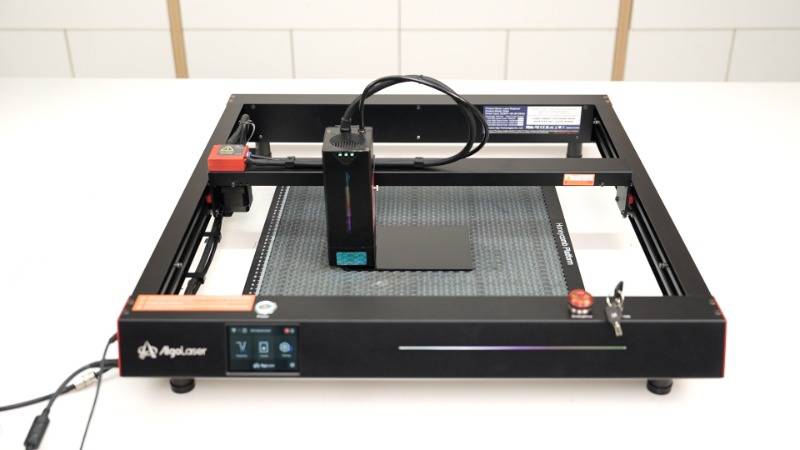

Acrylic, with its versatility and adaptability, has become a favorite material for artists, designers, and hobbyists alike. From personalized gifts to intricate decorations, acrylic offers endless possibilities. Central to unlocking its potential is the precision of laser engraving and cutting. We explore the art of acrylic engraving and cutting, focusing on the powerful combination of the Delta Laser Engraver and LightBurn software. Together, they empower users to transform their ideas into stunning creations with unparalleled accuracy and finesse.

Types Materials of Laser Engraving and Cutting on Acrylic

Laser engraving and cutting on acrylic materials can be categorized into different types based on the approach and outcome:

Vector Engraving/Cutting

Vector engraving involves cutting through the material along defined paths, creating precise shapes and outlines. This method is ideal for cutting out shapes, letters, and intricate designs from acrylic sheets. Vector cutting, on the other hand, involves cutting completely through the material along specified lines, resulting in clean edges and precise shapes.

Raster Engraving

Raster engraving, also known as image engraving, involves etching images or patterns onto the surface of the acrylic material. This technique is perfect for adding intricate details, textures, and gradients to acrylic surfaces, creating visually stunning designs and artworks.

The Role of LightBurn in Laser Engraving and Cutting on Acrylic

LightBurn serves as the backbone of laser engraving and cutting operations, offering a myriad of features tailored to the needs of users. Key functionalities of LightBurn include:

Vector and Raster Support

LightBurn seamlessly supports both vector and raster engraving/cutting, allowing users to work with a diverse range of designs and patterns.

Advanced Editing Tools

The software provides a suite of editing tools, including node editing, text manipulation, and shape creation, enabling users to customize their designs with ease.

Material Database

LightBurn features a built-in material database that offers pre-configured settings for various materials, including acrylic. This simplifies the setup process and ensures optimal engraving and cutting results.

Integration with Delta Laser Engraver

LightBurn integrates seamlessly with the Delta Laser Engraver, providing users with complete control over the engraving and cutting process. Users can import designs, adjust settings, and preview the results before sending the job to the laser engraver.

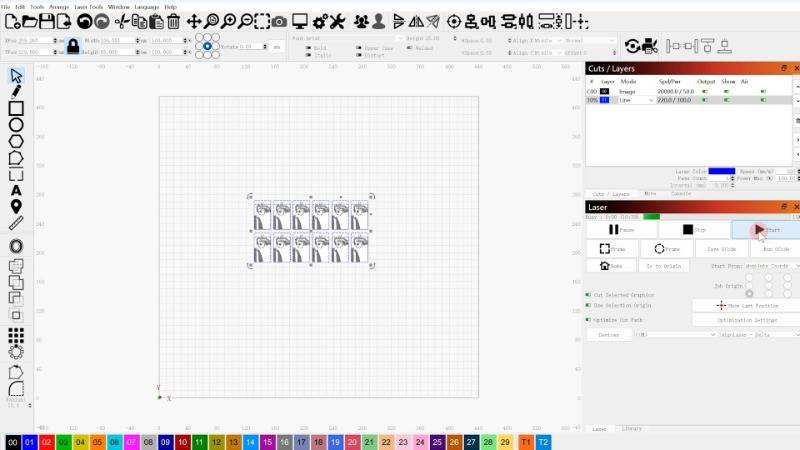

How Delta Engraves and Cut on Acrylic with LightBurn

The Delta Laser Engraver is renowned for its precision and reliability in engraving and cutting acrylic materials. When paired with LightBurn, it becomes a formidable tool for artisans and creators. Here's a step-by-step overview of how the process unfolds:

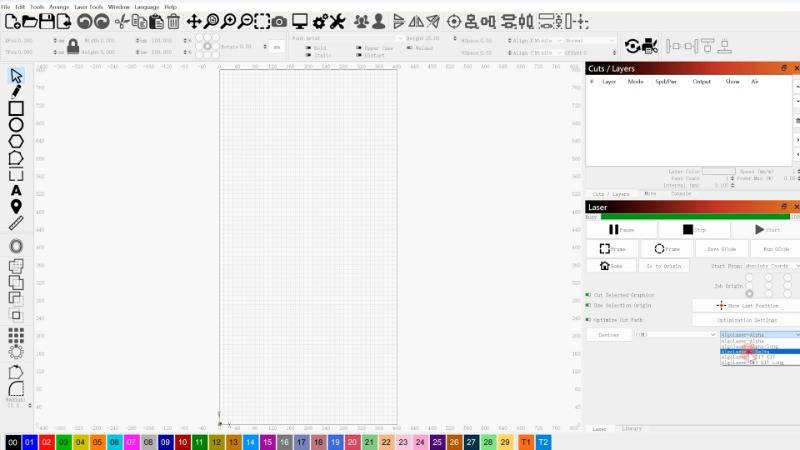

Step 1, power on the machine, and wait for the module stopping at the original point.

Step 2, open the LightBurn. Choose the corresponding machine. Wait for the console to display "OK" .

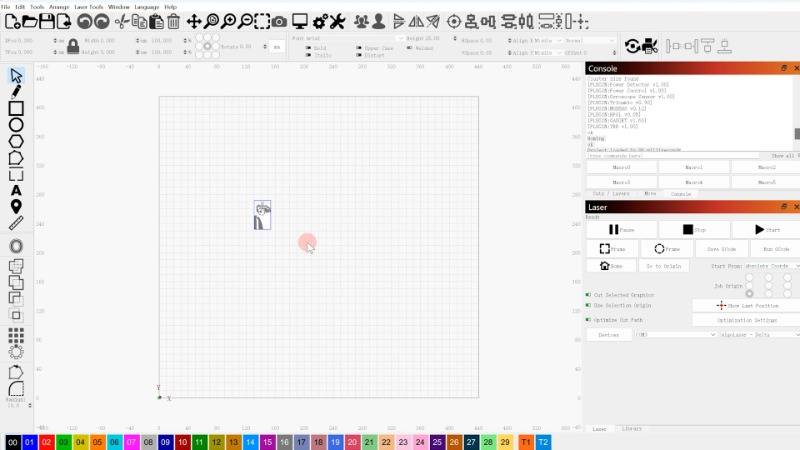

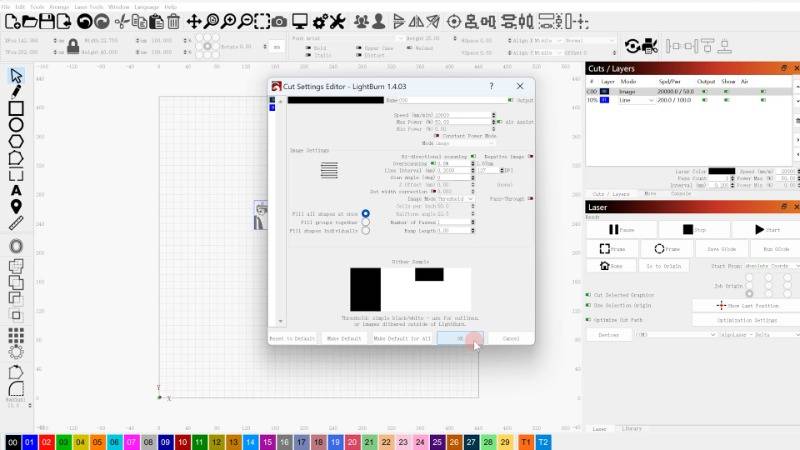

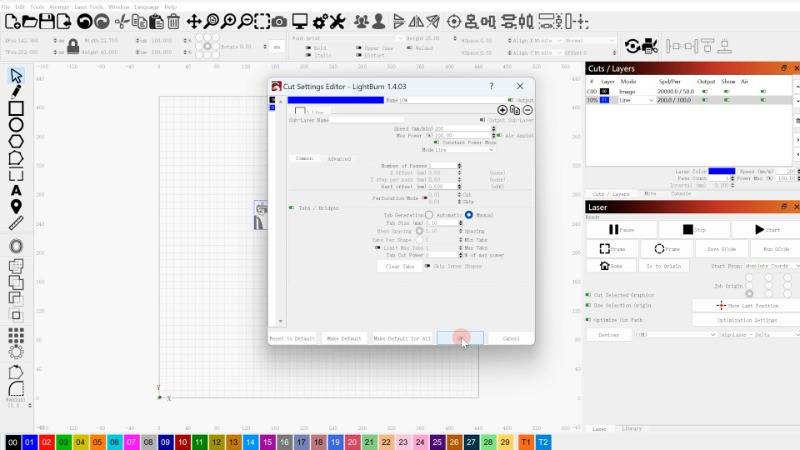

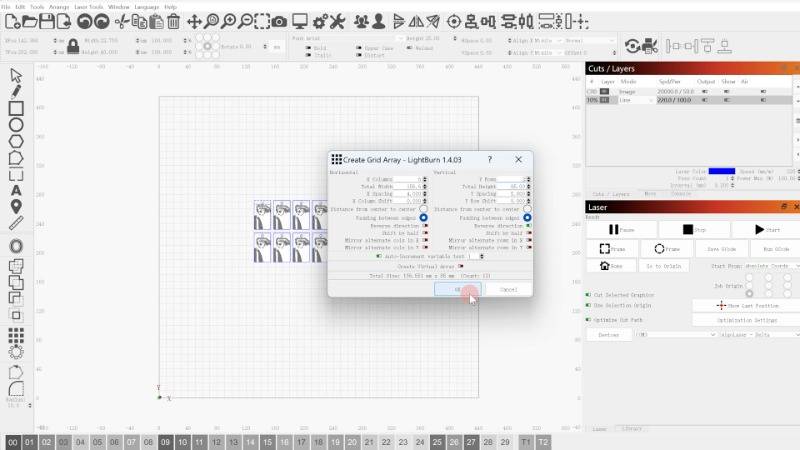

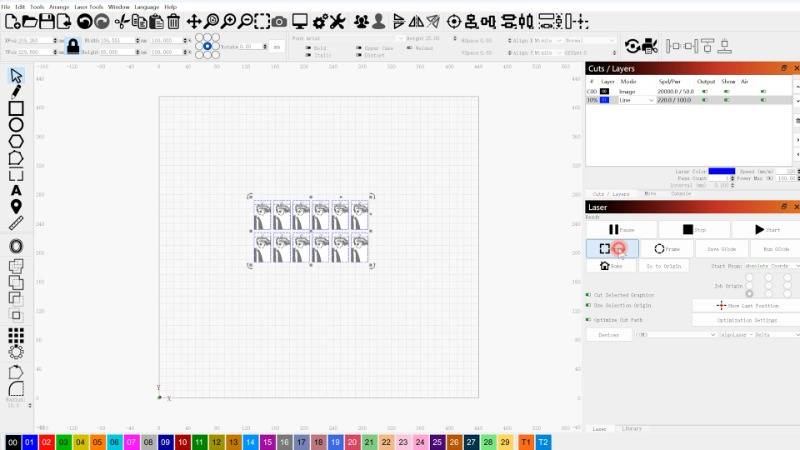

Step 3, drag the prepared pattern into the workspace. The recommended parameters for cutting and engraving acrylic are shown in the video. Click the icon for batch operation, you can set the rows and columns according to your own needs.

Step 4, click "Frame" button to determine the processing area.

Step 5, click "Start" .

FAQs About Laser Engraves and Cut on Acrylic with LightBurn

What types of acrylic materials can be engraved and cut with LightBurn and the Delta Laser Engraver?

LightBurn and the Delta Laser Engraver support a wide range of acrylic materials, including cast acrylic, extruded acrylic, and acrylic sheets of various thicknesses.

What is the maximum thickness of acrylic that can be cut with the Delta Laser Engraver?

The maximum thickness of acrylic that can be cut with the Delta Laser Engraver depends on the wattage of the laser tube. Generally, thicker acrylic materials require higher wattage lasers for clean cuts.

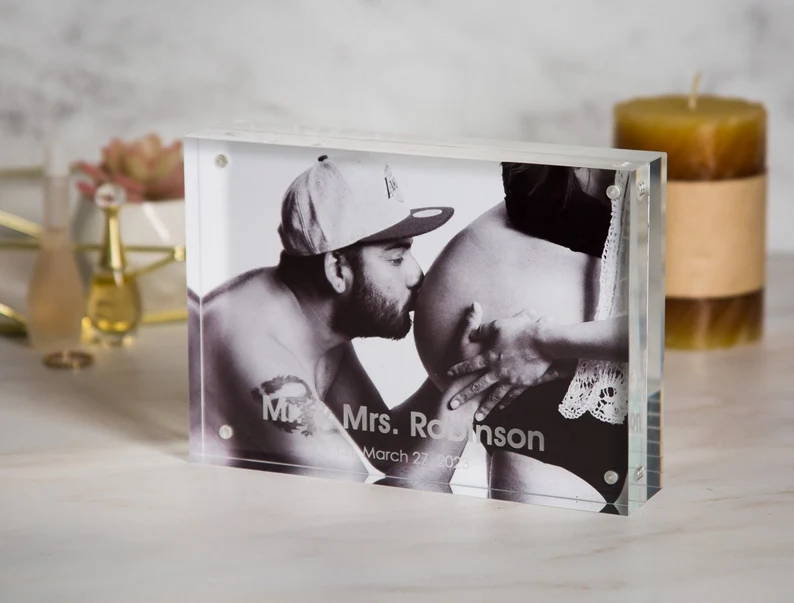

Can I engrave photographs or images onto acrylic with LightBurn?

Yes, LightBurn supports raster engraving, allowing users to engrave photographs, images, and complex designs onto acrylic surfaces with high precision and detail.

How do I prevent acrylic from melting or catching fire during the engraving/cutting process?

To prevent acrylic from melting or catching fire, it's important to use appropriate power, speed, and frequency settings in LightBurn. Additionally, utilizing air assist and proper ventilation can help dissipate heat and prevent combustion.

Can I engrave and cut acrylic in one pass with the Delta Laser Engraver?

Yes, the Delta Laser Engraver supports both engraving and cutting in a single pass, enabling efficient production and precise results.

Is it possible to engrave and cut intricate designs and text on acrylic with the Delta Laser Engraver?

Absolutely, the Delta Laser Engraver, in conjunction with LightBurn, can engrave and cut intricate designs, text, and patterns on acrylic materials with exceptional precision and clarity.

Conclusion

In conclusion, the combination of the Delta Laser Engraver and LightBurn software opens up a world of possibilities for acrylic engraving and cutting. By understanding the different techniques, leveraging the capabilities of LightBurn, and harnessing the precision of the Delta Laser Engraver, enthusiasts can elevate their projects to new heights of quality and craftsmanship. With proper preparation, execution, and finishing, the results are nothing short of breathtaking – stunning acrylic creations that captivate and inspire. The journey of acrylic engraving and cutting is not just about crafting objects; it's about unleashing creativity and turning visions into reality.

- Choosing a selection results in a full page refresh.